Abstract

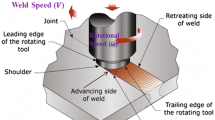

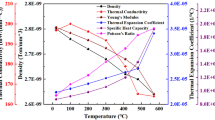

Heat flux characteristics are critical to good quality welding obtained in the important engineering alloy Al2024-T3 by the friction stir welding (FSW) process. In the present study, thermocouples in three different configurations were affixed on the welding samples to measure the temperatures: in the first configuration, four thermocouples were placed at equivalent positions along one side of the welding direction; the second configuration involved two equivalent thermocouple locations on either side of the welding path; while the third configuration had all the thermocouples on one side of the layout but with unequal gaps from the welding line. A three-dimensional, non-linear ANSYS computational model, based on an approach applied to Al2024-T3 for the first time, was used to simulate the welding temperature profiles obtained experimentally. The experimental thermal profiles on the whole were found to be in agreement with those calculated by the ANSYS model. The broad agreement between the two kinds of profiles validates the basis for derivation of the simulation model and provides an approach for the FSW simulation in Al2024-T3 and is potentially more useful than models derived previously.

Similar content being viewed by others

References

V. Soundararajan, S. Zekovic, and R. Kocacevic, Thermomechanical model with adaptive boundary conditions for friction stir welding of Al 6061, Int. J. Mach. Tool. Manuf., 45(2005), p. 1577.

Y.J. Chao, X. Qi, and W. Tang, Heat transfer in friction stir welding — experimental and numerical studies, J. Manuf. Sci. Eng., 125(2003), p. 138.

P. Prasanna, B.S. Rao, and G.K.M. Rao, Finite element modeling for maximum temperature in friction stir welding and its validation, Int. J. Adv. Manuf. Technol., 51(2010), p. 925.

S. Mandal, J. Rice, and A.A. Elmustafa, Experimental and numerical investigation of the plunge stage in friction stir welding, J. Mater. Process. Technol., 203(2008), p. 411.

H. Schmidt, J. Hattel, and J. Wert, An analytical model for the heat generation in friction stir welding, Modell. Simul. Mater. Sci. Eng., 12(2004), p. 143.

P.A. Colegrove, H.R. Shercliff, and R. Zettler, Model for predicting heat generation and temperature in friction stir welding from the material properties, Sci. Technol. Weld. Joining, 12(2007), p. 284.

W. Tang, X. Guo, J.C. McClure, L.E. Murr, and A. Nunes, Heat input and temperature distribution in friction stir welding, J. Mater. Process. Manuf. Sci., 7(1998), p. 163.

Y.J. Chao and X.H. Qi, Thermal and thermo-mechanical modeling of friction stir welding of aluminum alloy 6061-T6, J. Mater. Process. Manuf. Sci., 7(1998), p. 215.

H. Zhang, J.H. Huang, S.B. Lin, L. Wu, and J.G. Zhang, Temperature simulation of the preheating period in friction stir welding based on the finite element method, Proc. Inst. Mech. Eng. B., 220(2006), p. 1097.

N. Rajamanickam, V. Balusamy, G.M. Reddy, and K. Natarajan, Effect of process parameters on thermal history and mechanical properties of friction stir welds, Mater. Des., 30(2009), p. 2726.

P. Prasanna, B.S. Rao, G.K.M. Rao, and A. Prasad, Experimental and numerical evaluation of friction stir welds of AA6061-T6 aluminium alloy, J. Eng. Appl. Sci., 5(2010), p. 1.

P. Prasanna, Ch. Penchalayya, and D. Anandamohana Rao, Optimization and validation of process parameters in friction stir welding on AA6061 aluminum alloy using gray relational analysis, Int. J. Eng. Res. Appl., 3(2013), p. 1471.

K. Elangovan and V. Balasubramanian, Influences of pin profile and rotational speed of the tool on the formation of friction stir processing zone in AA2219 aluminium alloy, Mater. Sci. Eng. A, 459(2007), p. 7.

Z. Zhang and H.W. Zhang, Effect of contact model on numerical simulation of friction stir welding, Acta Metall. Sin., 44(2008), No. 1, p. 85.

H.B. Chen, K. Yan, T. Lin, S.B. Chen, C.Y. Jiang, and Y. Zhao, The investigation of typical welding defects for 5456 aluminum alloy friction stir welds, Mater. Sci. Eng. A, 433(2006), p. 64.

N.S. Shanmugam, G. Buvanashekaran, and K. Sankaranarayanasamy, Experimental investigation and finite element simulation of laser beam welding of AISI 304 stainless steel sheet, Exp. Tech., 34(2010), No. 5, p. 25.

K.C. Mills, Recommended Values of Thermophysical Properties for Selected Commercial Alloys, ASM International, 2002, p. 167.

Y.M. Hwang, Z.W. Kang, Y.C. Chiou, and H.H. Hsu, Experimental study on temperature distributions within the workpiece during friction stir welding of aluminum alloys, Int. J. Mach. Tool. Manuf., 48(2008), No. 7–8, p. 778.

M.Z.H. Khandkar, J.A. Khan, and A.P. Reynolds, Input torque based thermal model of friction stir welding of Al-6061, [in] Proceedings of the 6th International Conference: Trend in Welding Research, Arizona, 2002, p. 218.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yau, Y.H., Hussain, A., Lalwani, R.K. et al. Temperature distribution study during the friction stir welding process of Al2024-T3 aluminum alloy. Int J Miner Metall Mater 20, 779–787 (2013). https://doi.org/10.1007/s12613-013-0796-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-013-0796-2