Abstract

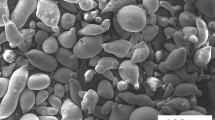

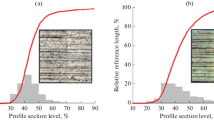

Three kinds of cast iron coatings were prepared by atmospheric plasma spraying. During the spraying, the mild steel substrate temperature was controlled to be averagely 50, 180, and 240°C, respectively. Abrasive wear tests were conducted on the coatings under a dry friction condition. It is found that the abrasive wear resistance is enhanced with the substrate temperature increasing. SEM observations show that the wear losses of the coatings during the wear tests mainly result from the spalling of the splats. Furthermore, the improved wear resistance of the coatings mainly owes to the formation of oxides and the enhancement in the mechanical properties with the substrate temperature increasing.

Similar content being viewed by others

References

S. Uozato, K. Nakata, and M. Ushio, Corrosion and wear behaviors of ferrous powder thermal spray coatings on aluminum alloy. Surf. Coat. Technol., 169–170(2003), p.691.

I. Ozdemir, T. Ueno, Y. Tsunekawa, and M. Okumiya, Cast iron coatings containing graphite structure by atmospheric plasma spraying, [in] Proceedings of 2004 International Thermal Spray Conference, Osaka, 2004, p.298.

M.F. Morks, Y. Tsunekawa, N.F. Fahim, and M. Okumiya, Microstructure and friction properties of plasma sprayed Al-Si alloyed cast iron coatings, Mater. Chem. Phys., 96(2006), p.170.

C.J. Li and W.Z. Wang, Quantitative characterization of lamellar microstructure of plasma-sprayed ceramic coatings through visualization of void distribution, Mater. Sci. Eng. A, 386(2004), p.10.

W.Z. Wang, Quantitative Characterization of Lamellar Microstructure of Plasma Sprayed Coatings and Relationship between Lamellar Microstructure and Properties of Coatings [Dissertation], Xi’an Jiaotong University, Xi’an, 2004, p.60.

C.J. Li and A. Ohmori, Relationships between the microstructure and properties of thermally sprayed deposits, J. Therm. Spray Technol., 11(2002), p.365.

C.J. Li, A. Ohmori, and R. McPherson, The relationship between microstructure and Young’s modulus of thermally sprayed ceramic coatings, J. Mater. Sci., 32(1997), p.997.

R. McPherson, A model for the thermal conductivity of plasma sprayed ceramic coatings, Thin Solid Films, 112(1984), p.89.

C.J. Li, G.J. Yang, and A. Ohmori, Relationship between particle erosion and lamellar microstructure for plasma-sprayed alumina coatings, Wear, 260(2006), p.1166.

Y.Z. Xing, C.J. Li, Q. Zhang, C.X. Li, and G.J. Yang, Influence of microstructure on the ionic conductivity of plasma-sprayed yttria-stabilized zirconia deposits, J. Am. Ceram. Soc., 91(2008), p.3931.

R.G. Castro, A.H. Bartlett, K.J. Hollis, and R.D. Fields, The effect of substrate temperature on the thermal diffusivity and bonding characteristics of plasma sprayed beryllium, Fusion Eng. Des., 37(1997), p.243.

S. Dallaire, Influence of temperature on the bonding mechanism of plasma-sprayed coatings, Thin Solid Films, 95(1982), p.237.

M. Mellali, P. Fauchais, and A. Grimaud, Influence of substrate roughness and temperature on the adhesion/cohesion of alumina coatings, Surf. Coat. Technol., 81(1996), p.275.

D.B. Marshall, T Noma, and A.G. Evans, A simple method for determining elastic-modulus-to-hardness ratios using Knoop indentation measurements, J. Am. Ceram., Soc., 65(1982), p.C175.

K. Niihara, R. Morena, and D.P.H. Hasselman, Evaluation of K 1c of brittle solids by the indentation method with low crack-to-indent ratios, J. Mater. Sci. Lett., 1(1982), p.13.

M.M. Lima, C. Godoy, J.C. Avelar-Batista, and P.J. Modenesi, Toughness evaluation of HVOF WC-Co coatings using non-linear regression analysis, Mater. Sci. Eng. A, 357(2003), p.337.

X. Jiang, J. Matejicek, and S. Sampath, Substrate temperature effects on the splat formation, microstructure development and properties of plasma sprayed coatings: Part II. Case study for molybdenum, Mater. Sci. Eng. A, 272(1999), p.189.

V. Pershin, M. Lufitha, S. Chandra, and J. Mostaghimi, Effect of substrate temperature on adhesion strength of plasma-sprayed nickel coatings, J. Therm. Spray Technol., 12(2003), p.370.

C.J. Li, Y.Z. Xing, Y. Li, C.X. Li, and G.J. Yang, Experimental simulation study of intersplat bonding formation by deposition of YSZ splats on preheated YSZ substrate, [in] Proceedings of 2008 International Thermal Spray Conference, Maastricht, 2008, p.1423.

Y.Z. Xing, C.J. Li, C.X. Li, and G.J. Yang, Influence of through-lamella grain growth on ionic conductivity of plasma-sprayed yttria stabilized zirconia as an electrolyte in solid oxide fuel cells, J. Power Sources, 176(2008), p.31.

G. Espie, A. Denoirjean, P. Fauchais, J.C. Labbe, J. Dubsky, O. Schneeweiss, and K. Volenik, In-flight oxidation of iron particles sprayed using gas and water stabilized plasma torch, Surf. Coat. Technol., 195(2005), p.17.

A.A. Syed, A. Denoirjean, P. Fauchais, and J.C. Labbe, On the oxidation of stainless steel particles in the plasma jet, Surf. Coat. Technol., 200(2006), p.4368.

Author information

Authors and Affiliations

Corresponding author

Additional information

This work was financially supported by the Special Fund for Basic Scientific Research of Central Colleges, Chang’an University (No. CHD2009JC131)

Rights and permissions

About this article

Cite this article

Xing, Yz., Wei, Ql., Jiang, Cp. et al. Abrasive wear behavior of cast iron coatings plasma-sprayed at different mild steel substrate temperatures. Int J Miner Metall Mater 19, 733–738 (2012). https://doi.org/10.1007/s12613-012-0620-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-012-0620-4