Abstract

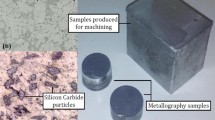

Metal matrix composites (MMCs) with high specific stiffness, high strength, improved wear resistance, and thermal properties are being increasingly used in advanced structural, aerospace, automotive, electronics, and wear applications. Aluminum alloy-silicon carbide composites were developed using a new combination of the vortex method and the pressure die-casting technique in the present work. Machining studies were conducted on the aluminum alloy-silicon carbide (SiC) composite work pieces using high speed steel (HSS) end-mill tools in a milling machine at different speeds and feeds. The quantitative studies on the machined work piece show that the surface finish is better for higher speeds and lower feeds. The surface roughness of the plain aluminum alloy is better than that of the aluminum alloy-silicon carbide composites. The studies on tool wear show that flank wear increases with speed and feed. The end-mill tool wear is higher on machining the aluminum alloy-silicon carbide composites than on machining the plain aluminum alloy.

Similar content being viewed by others

References

S. Barnes, I.R. Pashby, and A.B. Hashim, Effect of heat treatment on the drilling performance of aluminium/SiC MMC, Appl. Compos. Mater., 6(1999), p.121.

M. El-Gallab and M. Sklad, Machining of Al/SiC particulate metal-matrix composites Part I: Tool performance, J. Mater. Process. Technol., 83(1998), p.151.

S. Kannan and H.A. Kishawy, Tribological aspects of machining aluminium metal matrix composites, J. Mater. Process. Technol., 198(2008), p.399.

J.E. Allison and G.S. Cole, Metal-matrix composites in the automotive industry: Opportunities and challenges, JOM, 45(1993), p.19.

D.J. Lloyd, Particle reinforced aluminum and magnesium matrix composite, Int. Mater. Rev., 39(1994), p.1.

M.K. Surappa and P.K. Rohatgi, Preparation and properties of aluminium alloy ceramic particle composites, J. Mater. Sci., 16(1981), p.983.

M.K. Surappa, Aluminium matrix composites: Challenges and opportunities, Sadhana, 28(2003), p.319.

T. Sornakumar and A.S. Kumar, Machinability of bronzealumina composite with tungsten carbide cutting tool insert, J. Mater. Process. Technol., 202(2008), p.402.

A. Tharumarajah, Benchmarking aluminium die casting operations, Resour. Conserv. Recycl., 52(2008), p.1185.

R.N. Lumley, I.J. Polmear, H. Groot, and J. Ferrier, Thermal characteristics of heat-treated aluminum high-pressure die-castings, Scripta Mater., 58(2008), p.1006.

C. Gologlu and N. Sakarya, The effects of cutter path strategies on surface roughness of pocket milling of 1.2738 steel based on Taguchi method, J. Mater. Process. Technol., 206(2008), p.7.

R.A. Walsh, Handbook of Machining and Metalworking Calculations, McGraw-Hill, New York, 2001, p.5.22

M. Liang, T. Yeap, S. Rahmati, and Z.X. Han, Fuzzy control of spindle power in end milling processes, Int. J. Mach. Tools Manuf., 42(2002), p.1487.

T. Sornakumar, R. Krishnamurthy, and C.V. Gokularathnam, Machining performance of phase transformation toughened alumina and partially stabilised zirconia composite cutting tools, J. Eur. Ceram. Soc., 12(1993), p.455.

T.V. SreeramaReddy, T. Sornakumar, M. VenkataramaReddy, and R. Venkatram, Machinability of C45 steel with deep cryogenic treated tungsten carbide cutting tool inserts, Int. J. Refract. Met. Hard Mater., 27(2009), p.181.

A. Senthilkumar, A. Rajadurai, and T. Sornakumar, Machinability of hardened steel using alumina based ceramic cutting tools. Int. J. Refract. Met. Hard Mater., 21(2003), p.109.

A. Senthilkumar, A. Rajadurai, and T. Sornakumar, Wear behavior of alumina based ceramic cutting tools on machining steels, Tribol. Int., 39(2006), p.191.

S. Kalpakjian, Manufacturing Engineering and Technology, Addison Wesley Publishing Company, Reading, Massachusetts, 1995, p.594.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Sornakumar, T., Kathiresan, M. Machining studies of die cast aluminum alloy-silicon carbide composites. Int J Miner Metall Mater 17, 648–653 (2010). https://doi.org/10.1007/s12613-010-0369-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-010-0369-6