Abstract

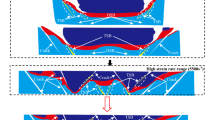

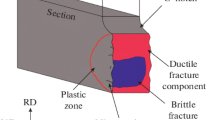

The multilayered 7XXX series aluminum alloy was impacted by 7.62 mm ogival projectiles at velocities ranging from 787 to 851 m·s−1. The deformed microstructure under various impacting velocities and fracture surfaces of different sections were investigated at different physical scales to determine the process of failure. Optical microscopy (OM), electron back-scattered diffraction (EBSD) and scanning electron microscopy (SEM) were used in the investigation. The results show that crater is constrained in the 7B52 front layer and two types of adiabatic shear bands which are transformed bands and deformed bands and different types of cracks are observed. Spall fracture is the significant failure mode of 7B52 front layer, and the resulting delamination leads to the presence of bending tensile fracture instead of the shear plugging. The ductile 7A01 layer blunts and deflects the spall crack tips, preventing the targets from full spall, and induces a constraint of 7A52 rear layer. The level of the constraint determines different fracture modes of 7A52 layer, accounting for the asymmetry of damage.

Similar content being viewed by others

References

Lesuer DR, Syn CK, Sherby OD, Wadseorth J, Lewandowski JJ, Hunt WH. Mechanical behaviour of laminated metal composites. Int Mater Rev. 1996;41(5):169.

Li XB, Zu GY, Wang P. Asymmetry in interface and bending property of Al/Cu/Al bimetallic laminates. Rare Met. 2014;33(5):556.

Radin J, Goldsmith W. Normal projectile penetration and perforation of layered targets. Int J Impact Eng. 1988;7(2):229.

Woodward RL. The interrelation of failure modes observed in the penetration of metallic targets. Int J Impact Eng. 1984;2(2):121.

Murr LE, Ramirez AC, Gaytan SM, Lopez MI, Martinez EY, Hermandez DH, Martinez E. Microstructure evolution associated with adiabatic shear bands and shear band failure in ballistic plug formation in Ti–6Al–4V targets. Mater Sci Eng A. 2009;516(1):205.

Sullivan A, Derry C, Robson JD, Horsfall I, Prangnell PB. Microstructure simulation and ballistic behaviour of weld zones in friction stir welds in high strength aluminium 7xxx plate. Mater Sci Eng A. 2011;528(9):3409.

Pedersen KO, Børvik T, Hopperstad OS. Fracture mechanisms of aluminium alloy AA7075-T651 under various loading conditions. Mater Des. 2011;32(1):97.

Woodward RL, Tracey SR, Crouch IG. The response of homogeneous and laminated metallic sheet material to ballistic impact. J Phys IV. 1991;1(C3):277.

Woodward RL, Cimpoeru SJ. A study of the perforation of aluminium laminate targets. Int J Impact Eng. 1998;21(3):117.

Deng Y, Zhang W, Cao Z. Experimental investigation on the ballistic resistance of monolithic and multi-layered plates against hemispherical-nosed projectiles impact. Mater Des. 2012;41:266.

Dey S, Børvik T, Teng X, Wierzbicji T, Hopperstad OS. On the ballistic resistance of double-layered steel plates: an experimental and numerical investigation. Int J Solids Struct. 2007;44(20):6701.

Kennedy C, Murr LE. Comparison of tungsten heavy-alloy rod penetration into ductile and hard metal targets: microstructural analysis and computer simulation. Mater Sci Eng A. 2002;325(1):131.

Deng YF, Zhang W, Yang YG, Shi LZ, Wei G. Experimental investigation on the ballistic performance of double-layered plates subjected to impact by projectile of high strength. Int J Impact Eng. 2014;70:38.

Mondal C, Mishra B, Jena PK, Kumar KS, Bhat TB. Effect of heat treatment on the behavior of an AA7055 aluminum alloy during ballistic impact. Int J Impact Eng. 2011;38(8):745.

Lee WM, Zikry MA. Microstructural characterization of a high-strength aluminum alloy subjected to high strain-rate impact. Metall Mater Trans A. 2011;42(5):1215.

Murr LE, Ayala A, Niou CS. Microbands and shear-related microstructural phenomena associated with impact craters in 6061-T6 aluminum. Mater Sci Eng A. 1996;216(1):69.

Seidt JD, Michael Pereira J, Gilat A, Revilock DM, Nandwana K. Ballistic impact of anisotropic 2024 aluminum sheet and plate. Int J Impact Eng. 2013;62:27.

Deshpande NU, Gokhale AM, Denzer DK, Liu J. Relationship between fracture toughness, fracture path, and microstructure of 7050 aluminum alloy: part I. Quantitative characterization. Metall Mater Trans A. 1998;29(4):1191.

Dumont D, Deschamps A, Brechet Y. On the relationship between microstructure, strength and toughness in AA7050 aluminum alloy. Mater Sci Eng A. 2003;356(1):326.

Deng XG. Study on the dynamic deformation behavior of pure Ti and Ti–xAl (x = 2, 4, 6) alloys. Beijing: General Research Institute for Nonferrous Metals; 2008. 20.

Field JE, Walley SM, Proud WG, Goldrein HT, Siviour CR. Review of experimental techniques for high rate deformation and shock studies. Int J Impact Eng. 2004;30(7):725.

Xu YB, Zhong WL, Chen YJ, Shen LT, Liu Q, Bai YL, Meyers MA. Shear localization and recrystallization in dynamic deformation of 8090 Al–Li alloy. Mater Sci Eng A. 2001;299(1):287.

Antoun T, Seaman L, Curran DR, Kanel GI, Razorenov SV, Utkin AV. Spall Fracture. New York: Springer; 2003. 10.

Acknowledgments

This study was financially supported by the National Basic Research Program of China (No. 2012CB619504) and the National Natural Science Foundation of China (No. 51274046).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, MY., Xiong, BQ., Wang, GJ. et al. Fracture mechanism of a laminated aluminum alloy plate during ballistic impact. Rare Met. 36, 737–745 (2017). https://doi.org/10.1007/s12598-015-0684-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-015-0684-1