Abstract

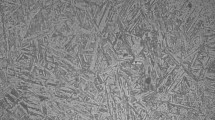

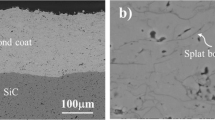

Active control of turbine blade tip clearance for aircraft engine continues to be a concern in engine operation, because turbine blades are subjected to wear and therefore cause an increasing tip clearance between the rotating blades and the shroud and also reduce the engine efficiency. In this work, a Ni-rich Ni3Al coating with γ′/γ two-phase microstructure was deposited by electron beam physical vapor deposition (EB-PVD), which worked as repairing the worn blade tips of single crystal blades. Nb molten pool was used to increase the molten pool temperature and thus to enhance the deposition rate. The microstructures and mechanical properties can be modified by the deposition temperatures and the following heat treatments. All coatings consist of γ′ and γ phases. At deposition temperature of 600 °C, a dense microstructure can be achieved to produce a coating with grain size of ~1 μm and microhardness of ~HV 477. After being heated for 4 h at a temperature of 1,100 °C, the coatings have a more uniform microstructure, and microhardness maintains at a high level of ~HV 292. Effect of Hf and Zr on EB-PVD Ni3Al repair coating will be further investigated.

Similar content being viewed by others

References

Bunker RS. A review of turbine blade tip heat transfer. Ann N Y Acad Sci. 2001;934(1):64.

Lakshminarayana B. Predicting the tip clearance flow in axial flow turbomachines. J Basic Eng. 1970;92(3):467.

Xiao XW, McCarter AA, Lakshminarayana B. Tip clearance effects in a turbine rotor: part I—pressure field and loss. J Turbomach. 2001;123(2):296.

McCarter AA, Xiao XW, Lakshminarayana B. Tip clearance effects in a turbine rotor: part II—velocity field and flow physics. J Turbomach. 2001;123(2):305.

Schell JD, Farr HJ. Abrasive ceramic matrix turbine blade tip and method for forming, USA Patent; No. 5952110; 1996.

Ameri AA, Steinthorsson E, Rigby DL. Effects of tip clearance and casing recess on heat transfer and stage efficiency in axial turbines. J Turbomach. 1999;12(4):683.

Boyle RJ, Haas JE, Katsanis T. Turbine endwall aerodynamics and heat transfer. J Propul Power. 1985;1(3):242.

Wiseman MW, Guo T. An investigation of life extending control techniques for gas turbine engines, In: Processing of the American Control Conference, Piscataway, 2001;5:3706.

Azad GS, Han JC, Boyle RJ. Heat transfer and flow on the squealer tip of a gas turbine blade. J Turbomach. 2000;122(4):725.

Wd Xing, Fan XX, Dong HG, Wu YD, Fu GQ, Liu Y. Regeneration technology and progress of waste superalloy. Chin J Rare Met. 2013;37(3):494.

Caron P, Khan T. Evolution of Ni-based superalloys for single crystal gas turbine blade applications. Aerosp Sci Technol. 1999;3(8):513.

Huang X, Miglietti W. Wide gap braze repair of gas turbine blades and vanes—a review. J Eng Gas Turb Power. 2012;134(4):1.

Bonifaz EA, Richards NL. Modeling cast IN-738 superalloy gas tungsten arc welds. Acta Mater. 2009;57(6):1785.

Nematzadeh F, Akbarpour MR, Parvizi S, Kokabi AH, Sadrnezhaad SK. Effect of welding parameters on microstructure, mechanical properties and hot cracking phenomenon in Udimet 520 superalloy. Mater Design. 2012;36(4):94.

Chen GQ, Fu XS, Wei YH, Li S, Zhou WL. Microstructure and wear properties of nickel-based surfacing deposited by plasma transferred arc welding. Surf Coat Technol. 2013;228(1):S276.

Su CY, Chou CP, Wu BC, Lih WC. Plasma transferred arc repair welding of the nickel-base superalloy IN-738LC. J Mater Eng Perform. 1997;6(5):619.

Gäumann M, Bezençon C, Canalis P, Kurz W. Single-crystal laser deposition of superalloys: processing–microstructure maps. Acta Mater. 2001;49(6):1051.

Mokadem S, Bezencxon C, Hauert A, Jacot A, Kurz W. Laser repair of superalloy single crystals with varying substrate orientations. Metall Mater Trans A. 2007;38(7):1500.

David SA, Vitek JM, Babu SS, Boatner LA, Reed RW. Welding of nickel base superalloy single crystals. Sci Technol Weld Join. 1997;2(2):79.

Singh J, Wolfe DE. Review nano and macro-structured component fabrication by electron beam physical vapor deposition (EB-PVD). J Mater Sci. 2005;40(1):1.

Movchan BA. EB-PVD technology in the gas turbine industry: present and future. JOM. 1996;48(11):40.

Lee KS, Jung KI, Heo YS, Kim TW, Jung Y, Paik U. Thermal and mechanical properties of sintered bodies and EB-PVD layers of Y2O3 added Gd2Zr2O7 ceramics for thermal barrier coatings. J Alloys Compd. 2010;507(2):448.

Aoki K, Izumi O. Ductility of intermetallic compound Ni3Al. J Jpn Inst Met. 1978;19(5):203.

Messmer RP, Briant CL. The role of chemical bonding in grain boundary embrittlement. Acta Metall. 1982;30(2):457.

Liu CT, Stiegler JO. Ductile ordered intermetallic alloys. Science. 1984;226(4675):636.

He J, Guo HB, Peng H, Gong SK. Microstructural mechanical and oxidation features of NiCoCrAlY coating produced by plasma activated EB-PVD. Appl Surf Sci. 2013;274(1):144.

Sanyal S, Waghmare UV, Subramanianc PR, Gigliottic MF. First-principles understanding of environmental embrittlement of the Ni/Ni3Al interface. Scripta Mater. 2010;63(4):391.

Xu ZH, He LM, Mu RD, He SM, Cao XQ. Preparation and characterization of La2Zr2O7 coating with the addition of Y2O3 by EB-PVD. J Alloys Compd. 2010;492(1):701.

Movchan BA, Yakovchuk KY. Graded thermal barrier coatings, deposited by EB-PVD. Surf Coat Technol. 2004;188(11):85.

Shee SK, Pradhan SK, De M. Effect of alloying on the microstructure and mechanical properties of Ni3Al. J Alloys Compd. 1998;265(1):249.

Guo JT, Sheng LY, Xie Y, Zhang ZX, Ovcharenko VE, Ye HQ. Microstructure and mechanical properties of Ni3Al and Ni3Al-1B alloys fabricated by SHS/HE. Intermetallics. 2011;19(2):137.

Schulson EM, Weihs TP, Viens DV, Baker I. The effect of grain size on the yield strength of Ni3Al. Acta Metall. 1985;33(9):1587.

Hall EO. The deformation and aging of mild steel: III discussion of results. Proc Phys Soc B. 1951;64(9):747.

Petch NJ. Cleavage strength of polycrystals. J Iron Steel Inst. 1953;174(5):25.

Meyers MA, Chawla KK. Mechanical Behavior of Materials. 2nd ed. Cambridge: Cambridge University Press; 2009. 212.

Acknowledgments

This work was financially supported by the Postdoctoral Science Foundation of China (No. 2013M540037).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sun, JY., Pei, YL., Li, SS. et al. Improved mechanical properties of Ni-rich Ni3Al coatings produced by EB-PVD for repairing single crystal blades. Rare Met. 36, 556–561 (2017). https://doi.org/10.1007/s12598-014-0340-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-014-0340-1