Abstract

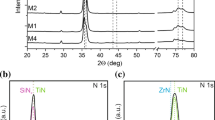

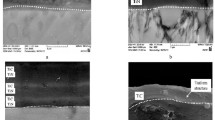

Multilayer hard coatings of TiC/Ti(C,N)/TiN on 35CrMo steel substrates were deposited by a chemical vapor deposition system (CVD). X-ray diffraction (XRD), scanning electron microscopy (SEM), and energy dispersive X-ray spectrometer (EDX) were used to analyze phase composition, morphology, and chemical composition of the coatings. The mechanical, corrosion, and wear properties of the produced coatings were primarily examined. The results indicate that multilayer coatings are consisted of TiC, Ti(C0.2N0.8), and TiN. The coatings surface is dense, and the thickness is about 11 μm. The adhesion between coatings and steel substrate was characterized by critical load (Lc) and is found to be about 70 N. The microhardness of the multilayer coatings is HV 2400, which is about 5 times as that of the 35CrMo steel substrate. The corrosion current of the coated sample is 4.368 × 10−5 A·cm−2, which decreases by one order of magnitude compared with the uncoated one (1.324 × 10−4 A·cm−2). Friction and wear tests show that the TiC/Ti(C,N)/TiN coatings with high hardness adhere well to the 35CrMo substrate and display good wear resistance and low friction coefficient under non-lubricated friction test at room temperature.

Similar content being viewed by others

References

Zhang JW, Lu LT, Shiozawa K, Zhou WN, Zhang WH. Effect of nitrocarburizing and post-oxidation on fatigue behavior of 35CrMo alloy steel in very high cycle fatigue regime. Int J Fatigue. 2011;33(7):880.

Yue W, Sun XJ, Wang CB, Fu ZQ, Liu YD, Liu JJ. A comparative study on the tribological behaviors of nitrided and sulfur-nitrided 35CrMo steel lubricated in PAO base oil with MoDTC additive. Tribol Int. 2011;44(12):2029.

Cigada A, Pastore T, Pedeferr P, Vicentini B. The sulfide stress corrosion cracking of high alloy stainless steels for oil and natural gas wells. Corros Sci. 1987;27(10–11):1213.

Yasuoka M, Wang PP, Murakami RI. Comparison of the mechanical performance of cutting tools coated by either a TiCxN1−x single-layer or a TiC/TiC0.5N0.5/TiN multilayer using the hollow cathode discharge ion plating method. Surf Coat Technol. 2012;206(8–9):2168.

Bao MD, Xu XB, Zhang HJ, Liu XP, Tian LH, Zeng ZX, Song YB. Tribological behavior at elevated temperature of multilayer TiCN/TiC/TiN hard coatings produced by chemical vapor deposition. Thin Solid Films. 2011;520(2):833.

Chen JY, Yu GP, Huang JH. Corrosion behavior and adhesion of ion-plated TiN films on AISI 304 steel. Mater Chem Phys. 2000;65(3):310.

Cheng YH, Browne T, Heckerman B, Meletis EI. Influence of the C content on the mechanical and tribological properties of the TiCN coatings deposited by LAFAD technique. Surf Coat Technol. 2011;205(16):4024.

Xiong J, Zhang F, Liu X, Zhao RP, Zhao XH, Tao BW. Epitaxial growth of MOCVD-derived YBCO films by modulation of Cu(tmhd)2concentration. Rare Met. 2014;33(1):70.

Yu YN, Song GH, Shen BT. Performance of TiC/a-C: H thin film, Chinese. J Rare Met. 2013;37(3):384.

Lee JK, Yang GS. Preparation of TiAlN/ZrN and TiCrN/ZrN multilayer by RF magnetron sputtering. Trans Nonferrous Met Soc China. 2009;19(4):795.

Xiao LS, Yan DR, He JN, Zhu L, Dong YC, Zhang JX, Li XZ. Nanostructured TiN coating prepared by reactive plasma spraying in atmosphere. Appl Surf Sci. 2007;253(18):7535.

Dreiling I, Haug A, Holzschuh H, Chassé T. Raman spectroscopy as a tool to study cubic Ti–C–N CVD coatings. Surf Coat Technol. 2009;204(6–7):1008.

Mariano JP, Lau KH, Alvarez E, Malhotra R, Hornbostel M, Krishnan G, Sanjurjo A. Multilayer coatings for corrosion protection of coal gasifier components. Mater Chem Phys. 2008;112(1):180.

Yigit R, Celik E, Findik F, Koksal S. Tool life performance of multilayer hard coatings produced by HTCVD for machining of nodular cast iron. Int J Refract Met Hard Mater. 2008;26(6):514.

Zhu L, He JN, Yan DR, Xiao LS, Dong YC, Zhang JX, Liao HL. Synthesis and microstructure observation of titanium carbonitride nanostructured coatings using reactive plasma spraying in atmosphere. Appl Surf Sci. 2011;257(20):8722.

Zhao YH, Lin GQ, Xiao JQ, Dong C, Wen LS. TiN-TiC multilayer films deposited by pulse biased arc ion plating. Vacuum. 2010;85(1):1.

Guo ZX, Xiong J, Yang M, Xiong SJ, Chen JZ, Bi SQ. Characterization and properties of MTCVD Ti (C, N) coated cemented carbide substrates with Fe/Ni binder. Int J Refract Met Hard Mater. 2010;28(2):238.

Casas B, Wiklund U, Hogmark S, Llanes L. Adhesion and abrasive wear resistance of TiN deposited on electrical discharge machined WC–Co cemented carbides. Wear. 2008;265(3–4):490.

Hogmark S, Jacobson S, Larsson M. Design and evaluation of tribological coatings. Wear. 2000;246(1–2):20.

Essen PV, Hoy R, Kamminga JD, Ehiasarian AP, Janssen GCAM. Scratch resistance and wear of CrNx coatings. Surf Coat Technol. 2006;200(11):3496.

Liu HB, Tao J, Xu J, Chen ZF, Gao Q. Corrosion and tribological behaviors of chromium oxide coatings prepared by the glow-discharge plasma technique. Surf Coat Technol. 2009;204(1–2):28.

Forn A, Picas JA, Fuentes GG, Elizalde E. Mechanical and tribological properties of TiCxN(1−x) wear resistant coatings. Int J Refract Met Hard Mater. 2001;19(4–6):507.

McCafferty E. Validation of corrosion rates measured by the Tafel extrapolation method. Corros Sci. 2005;47(12):3202.

Fenker M, Balzer M, Jehn HA, Kappl H, Lee JJ, Lee KH, Park HS. Improvement of the corrosion resistance of hard wear resistant coatings by intermediate plasma etching or multilayered structure. Surf Coat Technol. 2002;150(1):101.

Vancoille E, Celis JP, Roos JR. Tribological and structural characterization of a physical vapor deposited TiC/Ti(C, N)/TiN multilayer. Tribol Int. 1993;26(2):115.

Hubler R, Cozza A, Marcondes TL, Souza RB, Fiori FF. Wear and corrosion protection of 316-L femoral implants by deposition of thin films. Surf Coat Technol. 2001;142–144:1078.

Yang YL, Zhang D, Yan W, Zheng YR. Microstructure and wear properties of TiCN/Ti coatings on titanium alloy by laser cladding. Opt Laser Eng. 2010;48(1):119.

Bhatt A, Attia H, Vargas R, Thomson V. Wear mechanisms of WC coated and uncoated tools in finish turning of Inconel 718. Tribol Int. 2010;43(5–6):1113.

Takadoum J, Bennani HH, Allouard M. Friction and wear characteristics of TiN, TiCN and diamond-like carbon films. Surf Coat Technol. 1997;88(1–3):232.

Figueiredo MRD, Neidhardt J, Kaindl R, Reiter A, Tessadri R, Mitterer C. Formation mechanisms of low-friction tribo-layers on arc-evaporated TiC1−xNx hard coatings. Wear. 2008;265(3–4):525.

Acknowledgments

This study was financially supported by the National High Technology Research and Development Program of China (No.2007AA09Z202) and the Foundation of Sichuan Educational Committee (No.2012ZB164).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, J., Xue, Q., Li, SX. et al. Microstructure, corrosion and tribological properties of Ti(CN) multilayer coatings on 35CrMo steel by CVD. Rare Met. 39, 1314–1320 (2020). https://doi.org/10.1007/s12598-014-0305-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-014-0305-4