Abstract

In order to investigate the effect of erbium (Er) on the microstructure of orthorhombic Ti2AlNb-based alloys, four testing alloys were prepared by adding different contents of the rare earth metal Er to Ti–22Al–25Nb alloy and optical microscopy, X-ray diffraction, scanning electron microscopy, electron probe microanalysis, energy-dispersive spectrometry, and transmission electron microscopy were used. The results show that the addition of Er is capable of grain refining and the refinement effect is more obvious with increasing content of Er. The Er2O3 dispersoids formed by internal oxidation and Al3Er compound particles are observed in Er-doped alloys and the number of Er precipitates is increased with increasing Er addition. It is likely that the solubility of Er in the Ti2AlNb alloy is very low and Er precipitates tend to segregate at grain boundaries, which together with the surface activity of rare earth elements is supposed to decrease the prior B2 grain size of Ti–22Al–25Nb alloy effectively.

Graphical abstract

Rare earth element Er with a high-segregation tendency segregated at boundaries during cooling process and consequently led to the formation of Er-rich precipitates. These precipitates, acting as heterogeneous nucleation site, played an important role in refining grain size and functioning as obstacles to the migration of boundaries as well.

Similar content being viewed by others

References

Banerjee D, Gogia AK, Nandy TK, Joshi VA. A new ordered orthorhombic phase in a Ti3Al alloy. Acta Metall. 1988;36(4):871.

Chu F, Mitchell TE, Manjumdar B, Mriacle D, Nandy TK, Banerjee D. Elastic properties of O phase in Ti–Al–Nb alloys. Intermetallics. 1997;5(2):147.

Gogia AK, Nandy TK, Banerjee D, Carisey T, Strudel JL, Franchet JM. Microstructure and mechanical properties of orthorhombic alloy in the Ti–Al–Nb system. Intermetallics. 1998;6(7–8):741–8.

Nandy TK, Banerjee D. Creep of the orthorhombic phase based on the intermetallic Ti2AlNb. Intermetallics. 2000;8(5–6):915–28.

Mao Y, Li SQ, Zhang JW, Peng JH, Zou DX, Zhong ZY. Microstructure and tensile properties of orthorhombic Ti–Al–Nb alloys. Intermetallics. 2000;8(5–6):659–62.

Shagiev MR, Galeyev RM, Valiakhmetov OR, Safiullin RV. Improved mechanical properties of Ti2AlNb-based intermetallic alloys and composites. Adv Mater. 2009;59(13):105–8.

Muraleedharan K, Nandy TK, Banerjee D, Lele S. Phase stability and ordering behaviour of the O phase in Ti–Al–Nb alloys. Intermetallics. 1995;3(3):187.

Tang F, Nakazawa S, Hagiwara M. The effect of quaternary additions on the microstructures and mechanical properties of orthorhombic Ti2AlNb-based alloys. Mater Sci Eng A. 2002;329–331:492–8.

Germann L, Danerjee D, Guedou JY, Strudel JL. Effect of composition on the mechanical properties of newly developed Ti2AlNb-based titanium aluminide. Intermetallics. 2005;13(9):920–4.

Carisery TE, Gogia AK, Strudel J, Banerjee D. Titanium-based intermetallic alloys of the Ti2AlNb type with high yield strength and good creep resistance. European Patent, no. 0924308. 2002.

Carisey TE, Banerjee D, Franchet JM, Gogia AK. Titanium-based intermetallic alloys. US Patent, no. 6, 132, 526. 2000.

Yang SJ, Nam SW, Hagowara M. Phase identification and effect of W on the microstructure and micro-hardness of Ti2AlNb-based intermetallic alloys. J Alloy Compd. 2003;350(1–2):280–7.

Satoshi E, Kaneaki T, Koichi T. Improvement of room temperature ductility for Mo and Fe modified Ti2AlNb alloy. Mater Sci Eng A. 2010;528(1):355–62.

Tang F, Shizuo N, Hagowara M. Effect of boron microalloying on microstructure, tensile properties and creep behavior of Ti–22Al–20Nb–2W alloy. Mater Sci Eng A. 2001;315(1–2):147–52.

Li DQ, Wang QD, Ding WJ. Effects of Ho on the microstructure and mechanical properties of Mg-Zn-Ho-Zr magnesium alloys. Rare Met. 2011;30(2):131.

Chen YY, Si YF, Kong FT, Liu ZG, Li JW. Effects of yttrium on microstructures and properties of Ti–17Al–27Nb alloy. Trans Nonferrous Met Soc China. 2006;16(2):316–20.

Si YF, Cheng YY, Liu ZG, Kong FT. Influence of yttrium on microstructure and properties of Ti–23Al–25Nb alloy after heat treatment. Trans Nonferrous Met Soc China. 2006;16(Suppl 2):849–53.

Ke YB, Duan HP, Sun YR. Effect of yttrium and erbium on the microstructure and mechanical properties of Ti–Al–Nb alloys. Mater Sci Eng A. 2010;528(1):220–5.

Su MK, Zheng LJ, Lang B, Yan J, Zhang H. Microstructural evolution of a PM TiAl alloy during heat treatment in α+γ phase field. Rare Met. 2012;31(5):424.

Zhang YG, Hang YF, Chen G. High temperature intermetallic alloys. Beijing: National Defense Industry Press; 2001. p. 789–97.

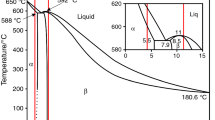

Zhang FZ, Gu LJ. Al-REE binary phase diagram. Beijing: China Academic Journal Electronic Publishing House; 1994–2010. p. 65.

Acknowledgments

This study was financially supported by the Science and Technology Ministry of China to the National High Technology “863” Project (No. 2012AA062302).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Dai, JR., Lu, HM., Cai, ZJ. et al. Grain refining of Er added to Ti–22Al–25Nb alloy and morphology of erbium precipitates. Rare Met. 32, 5–11 (2013). https://doi.org/10.1007/s12598-013-0006-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-013-0006-4