Abstract

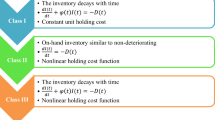

A combination of complementary and substitute products are very significant for any business industry to make all-round profit from various prospect. How deterioration affects complementary products or substitute products is discussed in this study. A deterministic production inventory control model for complementary and/or substitute items with a constant deterioration rate is studied. Here a shortage is also allowed. During shortage period, the demand of available item increases due to the shortage of substitute items. Similarly, the demand of available item decreases due to the shortage of complementary items during the said period. The demand is both price and stock dependent and the deteriorated items are salvaged. Here the total profit function consist of sales of product, inventory holding cost, green technology cost, carbon tax, production cost and salvage value. Numerical examples illustrate the theoretical results. The Pontryagin Maximum principle is used to solve the said optimal control inventory model. To justify the effectiveness of our model we check the sensitivity analysis. The results of this model are also graphically presented with the help of MATLAB software.

Similar content being viewed by others

Data availability

This manuscript has no associated data.

References

Arrow, K.J., Harris, T., Marschak, J.: Optimal inventory policy. Econometrica 19, 250–272 (1951)

Naddor, E.: Inventory Systems. Wiley, New Yeork (1966)

Padmannabha, G., Vrat, P.: Analysis of multi-systems under resource constraint, a nonlinear Goal programming approach. Eng. Cost Prod. Manag. 13(11), 104–112 (1990)

Bendaya, M., Rauof, A.: On the constraint multi-item single period inventory problem. Int. J. Prod. Manag. 13, 104–112 (1993)

Bhunia, A.K., Maiti, M.: A deterministic inventory problem for deteriorating items with dependent demand and shortages for finite time horizon. OPSEARCH, India 34(1), 51–61 (1997)

Mandal, M., Maiti, M.: Inventory of damageable items variable replenishment rate, stock-dependent demand and some units in hand. Appl. Math. Model. 23, 799–807 (1999)

Maity, K., Maiti, M.: Numerical approach of multi-objective optimal control problem in imprecise environment. Fuzzy Optim. Decis. Mak. 4, 313–330 (2005)

Maity, K., Maiti, M.: Possibility and necessity constraints and their defuzzification a multi-item production. Eur. J. Oper. Res. 177, 882–896 (2007)

Maity, K., Maiti, M.: A numerical approach to a multi-objective optimal inventory control problem for deteriorating multi-items under fuzzy inflation and discounting. Comput. Math. Appl. 55, 1794–1807 (2008)

Mandal, B.N., Phaujder, S.: An inventory model for deteriorating items and stock-dependent consumption rate. J. Oper. Res. Soc. 40, 483–488 (1989)

Agrawal, N., Smith, S.A.: Management of multi-item retail inventory system with demand substitution. Oper. Res. 48, 50–64 (2000)

Rao, H., Wu, M.Y., Wee, H.M.: Deteriorating item inventory model with shortage due to supplier in an integrated supply chain. Int. J. Syst. Sci. 20, 293–303 (2004)

Maity, K., Maiti, M.: Inventory of deteriorating complementary and substitute items with stock dependent demand. Am. J. Math. Manag. Sci. 25, 83–96 (2005)

Giri, R.N., Mondal, S.K., Maiti, M.: Analysis of pricing decision for substituteable and complementary products with a common retailer. Nat. Sci. Eng. 18(3), 190–202 (2016)

Mokhtari, H.: Economic order quantity for joint complementary and substitutable items. Math. Comput. Simul. 154, 34–47 (2018)

Mishra, U., Wa, J.Z., Sarkar, B.: A sustainable production-inventory model for a controllable carbon emissions rate under shortages. J. Clean. Prod. 256, 120268 (2020)

Taleizadeh, A.A., Soleymanfar, V.R., Govindan, K.: Sustainable economic production quantity models for inventory systems with shortage. J. Clean. Prod. 174, 1011–1020 (2018)

Duary, A., et al.: Advance and delay in payments with the price-discount inventory model for deteriorating items under capacity constraint and partially backlogged shortages. Alex. Eng. J. 61(2), 1735–1745 (2022)

Khatua, D., Maity, K., Kar, S.: A fuzzy production inventory control model using granular differentiability approach. Soft. Comput. 25, 2687–2701 (2021)

Hati, S., Maity, K.: Pollution control multi-objective inventory model of product-process innovation with stock dependent demand and gathering knowledge accumulation in finite time horizon. Contemp. Issues Bus. Econ. 1, 83–100 (2022)

Hati, S., Maity, K.: Reliability dependent imperfect production inventory optimal control fractional order model for uncertain environment under granular differentiability. Fuzzy Inf. Eng. 14(4), 379–406 (2022)

Hati, S., Maity, K.: Product process innovation model of fuzzy optimal control of nonlinear system with finite time horizon under granular differentiability concept. OPSEARCH 60, 753–775 (2023)

Hati, S.: A sustainable pollution control fuzzy production inventory model with imperfect and breakable items through Pontryagin maximum principle. J. Intell. Fuzzy Syst. 45(1), 1587–1601 (2023)

Hati, S., Panigrahi, G., Maity, K.: Stability analysis of fuzzy differential equation for prey-predator system under Z-number fuzzy and granular differentiability concept. RAIRO-Oper. Res. 58(1), 759–774 (2024)

Sawik, B.: Space mission risk, sustainability and supply chain: review, multi-objective optimization model and practical approach. Sustainability 15(14), 11002 (2023)

Sawik, T., Sawik, B.: Risk-averse decision-making to maintain supply chain viability under propagated disruptions. Int. J. Prod. Res. (2023)

Sawik, T.: Reshore or not reshore: a stochastic programming approach to supply chain optimization. Omega 118, 102863 (2023)

Sawik, B.: Selected multiple criteria supply chain optimization problems. In: Applications of management science, pp. 31–58 (2020)

Sana, S.S.: Price competition between green and non green products under corporate social responsible firm. J. Retail. Consum. Serv. 55, 102118 (2020)

Sana, S.S.: A structural mathematical model on two echelon supply chain system. Ann. Oper. Res. 315, 1997–2025 (2021)

Sana, S.S.: The effects of green house gas costs on optimal pricing and production lotsize in an imperfect production system. RAIRO-Oper. Res. 57, 2209–2230 (2023)

Sana, S.S.: Sale through dual channel retailing system-a mathematical approach. Sustain. Anal. Model. 2, 100008 (2022)

Pontryagin, L.S., Boltyanski, V.G.: The Mathematical Theory of Optimal Process. Inter Science, New York (1962)

Acknowledgements

The authors thank to Department of Science & Technology and Biotechnology, Govt of West Bengal [475(Sanc.)/ST/P/S &T/16 G-31/2018 dated 15.03.2019] for financial help.

Author information

Authors and Affiliations

Contributions

We developed a two items production inventory optimal control model for complementary and/or substitute items for deterioration with and without shortage under resource constraints.

Corresponding author

Ethics declarations

Conflict of interest

The author declare that there is no Conflict of interest regarding the publication of this article

Human or animal right

The authors declare that this research did not involve in human participation and animals.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Hati, S., Maity, K. Production inventory control model for deteriorating complementary and substitute items with shortage. OPSEARCH (2024). https://doi.org/10.1007/s12597-024-00770-4

Accepted:

Published:

DOI: https://doi.org/10.1007/s12597-024-00770-4