Abstract

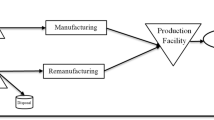

For decades, manufacturers have dealt with uncertain demands, and many solutions—such as manufacturing semi-finished products–have been presented to help manage the uncertainties. This paper considers the demand uncertainties in two echelons of a supply chain, unlike most of the field research, which has focused on the final customers’ demand uncertainty. In order to decrease the operating costs of a manufacturer, a model is proposed to use hybrid manufacturing in two levels of a supply chain with two echelons of manufacturers. The output of the presented model is the quantity of semi-finished products ordered to the decoupling point upstream manufacturer. The number of processes that must be done based upon Make to Stock, the order quantity of the decoupling point downstream manufacturers, and the order quantity of the final customers are obtained by the presented model as well. A numerical example and a vast sensitivity analysis are presented to better show the applicability of the presented model.

Similar content being viewed by others

References

Adan, I.J., Van der Wal, J.: Combining make to order and make to stock. OR Spectrum 20(2), 73–81 (1998)

Andreev, O.D., Koleva, N.V.: Opportunities for Applying Customer Order Decoupling Point Approach. The European Entrepreneurship: How Entrepreneurs (Should) Act in Global Business Environment (2013)

Da Rocha, C.G., Kemmer, S.L.: Method to implement delayed product differentiation in construction of high-rise apartment building projects. J. Constr. Eng. Manag. 139(10), 05013001 (2013)

Eivazy, H., Rabbani, M., Ebadian, M.: A developed production control and scheduling model in the semiconductor manufacturing systems with hybrid make-to-stock/make-to-order products. Int. J. Adv. Manuf. Technol. 45(9–10), 968–986 (2009)

Garg, A., Tang, C.S.: On postponement strategies for product families with multiple points of differentiation. IIE Trans. 29(8), 641–650 (1997)

Gupta, D., Benjaafar, S.: Make-to-order, make-to-stock, or delay product differentiation? A common framework for modeling and analysis. IIE Trans. 36(6), 529–546 (2004)

Hajfathaliha, A., Teimoury, E., Fathi, M.: Using queuing approach for locating the order penetration point in a two-echelon supply chain with customer loss. Int. J. Bus. Manag 6(1), p258 (2010)

Hanafy, M., ElMaraghy, H.: Developing assembly line layout for delayed product differentiation using phylogenetic networks. Int. J. Prod. Res. 53(9), 2633–2651 (2015)

Hedenstierna, P., Ng, A.H.: Dynamic implications of customer order decoupling point positioning. J. Manuf. Technol. Manag. 22(8), 1032–1042 (2011)

Jeong, I.J.: A dynamic model for the optimization of decoupling point and production planning in a supply chain. Int. J. Prod. Econ. 131(2), 561–567 (2011)

Jewkes, E.M., Alfa, A.S.: A queueing model of delayed product differentiation. Eur. J. Oper. Res. 199(3), 734–743 (2009)

Ji, J.H., Qi, L.L., GU, Q.L.: Study on CODP position of process industry implemented mass customization. Syst. Eng. Theory Pract. 27(12), 151–157 (2007)

Kalantari, M., Rabbani, M., Ebadian, M.: A decision support system for order acceptance/rejection in hybrid MTS/MTO production systems. Appl. Math. Model. 35(3), 1363–1377 (2011)

Kerkkänen, A.: Determining semi-finished products to be stocked when changing the MTS-MTO policy: case of a steel mill. Int. J. Prod. Econ. 108(1), 111–118 (2007)

Lee, H.L., Tang, C.S.: Modelling the costs and benefits of delayed product differentiation. Manag. Sci. 43(1), 40–53 (1997)

Liu, W., Mo, Y., Yang, Y., Ye, Z.: Decision model of customer order decoupling point on multiple customer demands in logistics service supply chain. Prod. Plan. Control 26(3), 178–202 (2015)

Mason-Jones, R., Towill, D.R.: Using the information decoupling point to improve supply chain performance. Int. J. Logist. Manag. 10(2), 13–26 (1999)

Naylor, J.B., Naim, M.M., Berry, D.: Leagility: integrating the lean and agile manufacturing paradigms in the total supply chain. Int. J. Prod. Econ. 62(1), 107–118 (1999)

Olhager, J.: Strategic positioning of the order penetration point. Int. J. Prod. Econ. 85(3), 319–329 (2003)

Olhager, J.: The role of the customer order decoupling point in production and supply chain management. Comput. Ind. 61(9), 863–868 (2010)

Rafiei, H., Rabbani, M.: Order partitioning and order penetration point location in hybrid make-to-stock/make-to-order production contexts. Comput. Ind. Eng. 61(3), 550–560 (2011)

Rahimnia, F., Moghadasian, M.: Supply chain leagility in professional services: how to apply decoupling point concept in healthcare delivery system. Supply Chain Manag. Int. J. 15(1), 80–91 (2010)

Wikner, J., Rudberg, M.: Integrating production and engineering perspectives on the customer order decoupling point. Int. J. Oper. Prod. Manag. 25(7), 623–641 (2005)

Sharda, B., Akiya, N.: Selecting make-to-stock and postponement policies for different products in a chemical plant: a case study using discrete event simulation. Int. J. Prod. Econ. 136(1), 161–171 (2012)

Sharman, G.: The rediscovery of logistics. Harvard Bus. Rev. 62(5), 71–79 (1984)

Shidpour, H., Da Cunha, C., Bernard, A.: Analyzing single and multiple customer order decoupling point positioning based on customer value: a multi-objective approach. Proc. CIRP 17, 669–674 (2014)

Soman, C.A., Van Donk, D.P., Gaalman, G.: Comparison of dynamic scheduling policies for hybrid make-to-order and make-to-stock production systems with stochastic demand. Int. J. Prod. Econ. 104(2), 441–453 (2006)

Soman, C.A., Van Donk, D.P., Gaalman, G.J.: Capacitated planning and scheduling for combined make-to-order and make-to-stock production in the food industry: an illustrative case study. Int. J. Prod. Econ. 108(1), 191–199 (2007)

Sun, X.Y., Ji, P., Sun, L.Y., Wang, Y.L.: Positioning multiple decoupling points in a supply network. Int. J. Prod. Econ. 113(2), 943–956 (2008)

Swaminathan, J.M., Tayur, S.R.: Managing broader product lines through delayed differentiation using vanilla boxes. Manag. Sci. 44(12-part-2), S161–S172 (1998)

Teimoury, E., Fathi, M.: An integrated operations-marketing perspective for making decisions about order penetration point in multi-product supply chain: a queuing approach. Int. J. Prod. Res. 51(18), 5576–5596 (2013)

Teimoury, E., Modarres, M., Khondabi, I.G., Fathi, M.: A queuing approach for making decisions about order penetration point in multiechelon supply chains. Int. Journal of Adv. Manuf. Technol. 63(1–4), 359–371 (2012)

Van Donk, D.P.: Make to stock or make to order: the decoupling point in the food processing industries. Int. J. Prod. Econ. 69(3), 297–306 (2001)

Vanteddu, G., Chinnam, R.B.: Supply chain focus dependent sensitivity of the point of product differentiation. Int. J. Prod. Res. 52(17), 4984–5001 (2014)

Wang, F., Lin, J., Liu, X.: Three-dimensional model of customer order decoupling point position in mass customisation. Int. J. Prod. Res. 48(13), 3741–3757 (2010)

Wikner, J.: A service decoupling point framework for logistics, manufacturing, and service operations. Int. J. Serv. Sci. 4(3–4), 330–357 (2012)

Wikner, J., Rudberg, M.: Integrating production and engineering perspectives on the customer order decoupling point. Int. J. Oper. Prod. Manag. 25(7), 623–641 (2005)

Wong, H., Wikner, J., Naim, M.: Analysis of form postponement based on optimal positioning of the differentiation point and stocking decisions. Int. J. Prod. Res. 47(5), 1201–1224 (2009)

Wong, H., Wikner, J., Naim, M.: Evaluation of postponement in manufacturing systems with non-negligible changeover times. Prod. Plan. Control 21(3), 258–273 (2010)

Wu, M.C., Jiang, J.H., Chang, W.J.: Scheduling a hybrid MTO/MTS semiconductor fab with machine-dedication features. Int. J. Prod. Econ. 112(1), 416–426 (2008)

Vanteddu, G., Chinnam, R.B.: Supply chain focus dependent sensitivity of the point of product differentiation. Int. J. Prod. Res. 52(17), 4984–5001 (2014)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ghalehkhondabi, I., Sormaz, D. & Weckman, G. Multiple customer order decoupling points within a hybrid MTS/MTO manufacturing supply chain with uncertain demands in two consecutive echelons. OPSEARCH 53, 976–997 (2016). https://doi.org/10.1007/s12597-016-0265-6

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12597-016-0265-6