Abstract

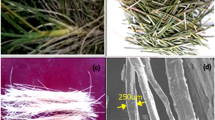

In this study, epoxy resin vacuum infused in screwpine fibres has been used to investigate whether it can emerge as a realistic alternative to glass fibre composites. The screwpine fibres were mercerized and treatment conditions were selected on the basis of cellulose percentage and fibre surface morphology. Experimental design, based on Taguchi’s L9 Orthogonal Array showed that mercerization with 5 % NaOH for 45 min at 75 °C offered optimum results. ANOVA illustrated that temperature was in fact the most influential parameter followed by NaOH concentration and time. ATR-FTIR was used to analyze the fibre-composition change as a result of mercerization. Compression testing of composites showed that alkali-treated fibre composites withstand more load than untreated fibre composites at 5, 10, and 15 % (weight basis) fibre loadings. Fatigue test also confirmed that results are significantly better when composites are made from treated fibre. The outcomes indicate that screwpine fibres may be used as a potential reinforcing material for low-load bearing composites such as automobile components.

Similar content being viewed by others

References

Mohanty K. Amar, Manjusri Misra, Lawrence T. Drzal, Susan E. Selke, Bruce R. Harte, Georg Hinrichsen (2005) Natural fibers, biopolymers and biocomposites. CRC Press. Carbohydrate Polymers, Volume 68, Issue 4, p. 809

Ramadevi P, Sampathkumar D, Srinivasa CV, Bennehalli B (2012) Effect of alkali treatment on water absorption of single cellulosic abaca fiber. Bioresources 7(3):3515–3524

Faruk O, Bledzki K, Hans-Peter F, Mohini S (2012) Biocomposites reinforced with natural fibers. Progress in polymer science. Elsevier Publ 37(11):1552–1596

Cristaldi G, Latteri A, Recca G, Cicala G (2010) Composites Based on Natural Fibre Fabrics, Woven Fabric Engineering, Polona Dobnik Dubrovski (Ed.), ISBN: 978-953-307-194-7, InTech, Available from: http://www.intechopen.com/books/woven-fabric-engineering/composites-based-on-naturalfibre-fabrics

Malkapuram R, Kumar V, Negi YS (2009) Recent development in natural fiber reinforced polypropylene composites. J Reinf Plast Compos 28(10):1169–1189

Kim J, N. N (2010) Mercerization of sisal fibers: effect of tension on mechanical properties of sisal fiber and fiber-reinforced composites. Elsevier Publ Compos A: Appl Sci Manuf 41(9):1245–1252

Dittenber D, Gangarao VS (2012) Critical review on publication on natural composites in infrastructure. Elsevier Publ Compos A: Appl Sci Manuf 43(8):1419–1429

Barreto ACH, Rosa DS, Fechine PBA, Mazzetto SE (2011) Properties of sisal fibres treated by alkali solution and their application into cardanol-based biocomposites. Elsevier Publ Compos A: Appl Sci Manuf 42(5):492–500

Xie Y, Callum ASH, Zefang X, Holger M, Carsten M (2010) Silane coupling agents used for natural fiber/polymer composite. Elsevier Publ Compos A: Appl Sci Manuf 41(7):806–819

Mylsamy K, Rajendran I (2011) Influence of alkali treatment and fibre length on mechanical properties of short agave fibre reinforced epoxy composites. Elsevier Publ Mater Des 32(8–9):4629–4640

Jahn A, Schroder MW, Futing M, Schenzel K, Diepenbrock W. Characterization of alkali treated flax fibres by means of FT Raman spectroscopy and environmental scanning electron microscopy. Spectrochimica Acta Part A: Molecular and Biomolecular Spectroscopy 58(10): 2271–2279

Towo A, Ansell P (2007) Fatigue evaluation and dynamic thermal analysis of sisal fibre-thermosetting resin composites. Elsevier Publ Compos Sci Technol 68(3–4):925–932

Towo A, Ansell P (2007) Fatigue of sisal fibre reinforced composites: constant life diagrams and hysteresis loop capture. Elsevier Publ Compos Sci Technol 68(3–4):915–924

Callister WD, Rethwisch D (2009) Material science and engineering, an introduction, 8th edition. Wiley, New York

Alves C, Ferrão P, Silva A, Freitas M, Rodrigues LB, Alves DE (2010) Ecodesign of automotive components making use of natural jute fiber composites. J Clean Prod 18(4):313–327

Abral H, Andriyanto H, Rendi S, Sapuan SM, Ishak MR (2012) Mechanical properties of screw pine (Pandanus Odoratissimus) fibers unsaturated polyester composites. Polym Plast Technol Eng 51(5):500–506

Brink M, & Achigan-Dako EG (2012) Fibres (Vol. 16), p 346. PROTA

Barreto ACH, Rosa DS, Fechine PBA, Mazzetto SE (2011) Properties of sisal fibres treated by alkali solution and their application into cardanol-based biocomposites. Compos A: Appl Sci Manuf 42(5):492–500

Sipiao BLS, Paiva RLM, Goulart SAS, Mulinari DR (2011) Effect of chemical modification on mechanical behavior of polypropylene reinforced pineapple crown fibres composites. Elsevier Publ Procedia Eng 10:2028–2033

Van Soest PJ (1963) Using of detergents in the analysis of fibrous feeds. A rapid method for the determination of fibre and lignin. J Assoc Off Anal Chem 46:828

Tecator Application SubNote (ASN 3431). The determination of neutral detergent fibre in feed

Tecator Application SubNote (ASN 3436). The determination of acid detergent fibre of feed

Tecator Application SubNote (ASN 3438). The determination of acid detergent lignin in feed

Tecator Application SubNote (ASN 304). Fibre determination using the FibreTec I and M systems

SOOCHETA, V. (2009). Investigation into the Textile applications of fibres extracted from Pandanus Utilis. Personal communication & presentation available at http://vcampus.uom.ac.mu/researchweek/conference2009/uploads/posters/paper1965368.ppt

Ashby MF (2011) Materials selection in mechanical design, 4th edn. Elsevier, USA, p 149

Deepa B, Abraham E, Cherian BM, Bismarck A, Blaker JJ, Pothan LA (2011) Structure, morphology and thermal characteristics of banana nano fibers obtained by steam explosion. Bioresour Technol 102:1988–1997

Dufresne A, Dupeyre D, Vignon MR (2000) Cellulose micro fibrils from potato tuber cells: processing and characterization of starch–cellulose micro fibril composites. J Appl Polym Sci 76:2080–2092

Strömberg C, Guralnick R, Simison B, Speer B, & Cordero A (1998) Laboratory I: Introduction to plant structure. Berkeley: The Museum of Paleontology of the University of California. http://www.ucmp.berkeley.edu/IB181/VPL/Ana/AnaTitle.html

Abraham E, Deepa B, Pothan LA, Jacob M, Thomas S, Cvelbar U, And Anandjiwala R (2011) Extraction of nanocellulose fibrils from lignocellulosic fibres. Elsevier Publ Carbohydr Polym 86(4):1468–1475

Bledzki A, Mamun AA, Volk J (2010) Barley husk and coconut shell reinforced polypropylene composites: the effect of fibre physical, chemical and surface properties. Elsevier Publ Compos Sci Technol 70(5):840–846

Vas s, Ferenc R, Tibor C (2009) Active fiber length distribution and its application to determine the critical fiber length. Elsevier Publ Polym Test 28:752–759

Kristiina O, Mathew AP, Långström R, Nyström B, Kuruvilla J (2009) The influence of fibre microstructure on fibre breakage and mechanical properties of natural fibre reinforced polypropylene. Elsevier Publ Compos Sci Technol 69:1847–1853

Joshi SV, Drzal LT, Mohanty AK, Arora S (2003) Are natural fiber composites environmentally superior to glass fiber reinforced composites. Elsevier Publ Compos A: Appl Sci Manuf 35(3):371–376, March 2004

Vasiliev VV, Morozov EV (2001) Mechanics and analysis of composites. Elsevier, New York

Kaw AK (2006) Mechanics of composite material, 2nd edn. CRC Taylor and Francis, Boca Raton

Prasanna GV, Subbaiah KV (2013) Modification, flexural, impact, compressive properties & chemical resistance of natural fibres reinforced blend composites. Malays Polym J 8(1):38–44

Riedel U (2012) Bio-composites: long natural fibre-reinforced biopolymers. Elsevier Publ Polym Sci: Compr Ref 10:295–315

Ross J (1988) Taguchi techniques for quality engineering. McGraw-Hill, United States

Acknowledgments

The authors gratefully acknowledge the timely help rendered by the following staff of the University of Mauritius: Mr. R Sheik Manoga, Ms. Vencatasamy, Mr. Awatar, Mrs. Seeruttun, Mrs. Bissoundoyal, Mrs. Nathalie, Mr. Debiddin and his team.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Deesoruth, A., Ramasawmy, H. & Chummun, J. Investigation into the use of alkali treated screwpine (Pandanus Utilis) fibres as reinforcement in epoxy matrix. Int J Plast Technol 18, 263–279 (2014). https://doi.org/10.1007/s12588-014-9082-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12588-014-9082-z