Abstract

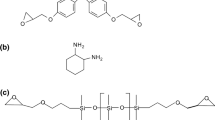

The blends of diglycidyl ether of bisphenol-A (DGEBA) and poly (hydroxyl ether of bisphenol-A) or phenoxy were synthesized by melt blending at 120 °C. These blends were cured by an aromatic amine hardener, 4,4′- diaminodiphenyl sulphone (DDS). The experiments were performed to study the different amount of phenoxy (10 to 40 parts per hundred resins) on mechanical and electrical properties of the DGEBA/phenoxy blends, such as tensile properties, flexural properties, impact strength, Rockwell hardness, and volume resistivity. The oxirane group of DGEBA epoxy resin reacts with hydroxyl group of phenoxy which provides good toughness to the epoxy resin. The tensile strength, tensile modulus, flexural strength, flexural modulus, heat deflection temperature and volume resistivity of DGEBA/phenoxy blends decreased with increasing the amount of phenoxy from 10 to 40 parts per hundred resins (phr). The opposite trend was observed in impact strength and Rockwell hardness of all DGEBA/phenoxy blends which were increased with increasing the phenoxy content from 10 to 20 phr, but then decreased upto 40 phr. The SEM studies revealed that the DGEBA/phenoxy blends show a multiphase system with an increase in the phenoxy content from 10 to 40 phr. due to inconvenience of mixing of two phases.

Similar content being viewed by others

References

May CA (1988) Epoxy resins chemistry and technology. Marcel Dekker, New York, p 1

Park SJ, Jin FL, Lee JR (2004) Mater Sci Eng A 374:109

Rowe EH, Siebert AR, Drake RS (1970) Mod Plast 47:110

Sultan JM, Magarry F (1973) Polym Eng Sci 13:29

Bucknell CB (1977) Toughened plastics. Applied Science Publishers, London

Guo Q, Peng X, Wang Z (1989) Polymer 21:593

Bucknal CB, Partridge IK (1983) Polymer 24:639

Hourston DJ, Lane JM (1992) Polymer 33:1379

Cardwell BJ, Yee AF (1994) Polym Mater Sci Eng 70:254

Dinakaran K, Alagar M (2002) J Appl Polym Sci 85:2853–2861

Dyakonov T, Mann PJ, Chen Y, Stevenson WTK (1996) Polym Degrad Stab 54:67–83

Bucknal CB, Partridge IK (1996) Polym Eng Sci 26:54

Bucknal CB, Gomez CM, Quintard I (1994) Polymer 35:353

Song X, Zheng S, Huang J, Zhu P, Guo Q (2001) Miscibility and mechanical properties of tetrafunctional epoxy resin/phenolphthalein poly (ether ether ketone) blends. J Appl Polym Sci 79(4):598–607

Hseih HK, Su CC, Woo EM (1998) Cure kinetics and inter-domain etherification in an amine-cured phenoxy/epoxy system. Polymer 39(11):2175–2183

Gupta A, Singhal R, Nagpal AK (2005) J Appl Polym Sci 96:537–549

Arundhati SR, Nagpal AK (2010) Int J Plast Technol 13(2)

Mark HF, Bikales NM, Overberger CG, Menges G (1986) Encyclopedia of Polymer Engineering and Science: NY 5:507

Woo EM, Hseih HK (1998) Polymer 39(1):7–13

Guo Q (1995) Polymer 36(25):4753–4760

Acknowledgement

The authors wish to thank to the Director, HBTI, Kanpur. The authors would also like to thank Smt. Rekha & Anil Sainy, IIC, IIT, and Roorkee for the SEM and TGA analysis of samples. We greatfully acknowledge to Dr. Vijay Mathur, Director, CIPET, Lucknow for mechanical and electrical testing of samples.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Dixit, V., Nagpal, A.K. & Singhal, R. Influence of phenoxy modifier on mechanical, electrical and morphological properties of epoxy/DDS system. Int J Plast Technol 14, 38–52 (2010). https://doi.org/10.1007/s12588-010-0001-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12588-010-0001-7