Abstract

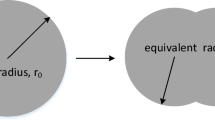

The macroscopic behaviour of an assembly of polydisperse spherical particles is studied using a numerical model based on discrete element method (DEM), which accounts for the microscopic interactions between individual particles and their damage. DEM models particle–particle interactions enabling to understand the influence of microscopic particle–particle interactions on the macroscopic response. The method is used to stimulate the mechanical response of a polydisperse particle assembly under uniaxial compressive load. The influence of damage rate and the initial packing fraction on the macroscopic stress–strain response is investigated. The analysis shows that the initial nonlinear elastic behaviour is influenced by the initial packing factor, whereas the critical stress is influenced by both initial packing fraction and damage rate. It is also observed that critical stress occurs when the assembly reaches a particular damage state. Furthermore, the failure behaviour of different sized particles within a polydisperse assembly is also investigated. The experimental data from the literature show that the crush strength of the particle of given size is observed to vary over a range. Such variation of crush strengths for a given particle size is also implemented in the present work.

Similar content being viewed by others

References

Pupeschi, S., Knitter, R., Kamlah, M.: Effective thermal conductivity of advanced ceramic breeder pebble beds. Fusion Eng. Des. 116, 73–80 (2017)

Reimann, J., Hermsmeyer, S.: Thermal conductivity of compressed ceramic breeder pebble beds. Fusion Eng. Des. 61, 345–351 (2002)

Moscardini, M., Gan, Y., Pupeschi, S., Kamlah, M.: Discrete element method for effective thermal conductivity of packed pebbles accounting for the Smoluchowski effect. Fusion Eng. Des. 127, 192–201 (2018)

Piazza, G., Jörg Reimann, E., Günther, R.K., Roux, N., Lulewicz, J.D.: Characterisation of ceramic breeder materials for the helium cooled pebble bed blanket. J. Nucl. Mater. 307, 811–816 (2002)

Peeketi, Akhil Reddy, Moscardini, Marigrazia, Vijayan, Akhil, Gan, Yixiang, Kamlah, Marc, Annabattula, Ratna Kumar: Effective thermal conductivity of a compacted pebble bed in a stagnant gaseous environment: An analytical approach together with DEM. Fusion Eng. Des. 130, 80–88 (2018)

Cundall, P.A., Strack, O.D.L.: A discrete numerical model for granular assemblies. Geotechnique 29(1), 47–65 (1979)

Annabattula, R.K., Gan, Y., Zhao, S., Kamlah, M.: Mechanics of a crushable pebble assembly using discrete element method. J. Nucl. Mater. 430, 90–95 (2012)

Lew, V., Jon, T., Ying, A., Abdou, M.: A discrete element method study on the evolution of thermomechanics of a pebble bed experiencing pebble failure. Fusion Eng. Des. 89(7), 1151–1157 (2014)

Gan, Y., Kamlah, M.: Discrete element modelling of pebble beds: with application to uniaxial compression tests of ceramic breeder pebble beds. J. Mech. Phys. Solids 58(2), 129–144 (2010)

Ying, A., Akiba, M., Boccaccini, L.V., Casadio, S., Dell’Orco, G., Enoeda, M., Hayashi, K., Hegeman, J.B., Knitter, R., van der Laan, J., et al.: Status and perspective of the R&D on ceramic breeder materials for testing in ITER. J. Nucl. Mater. 367, 1281–1286 (2007)

Reimann, J., Boccaccini, L., Enoeda, M., Ying, A.Y.: Thermomechanics of solid breeder and Be pebble bed materials. Fusion Eng. Des. 61, 319–331 (2002)

Zaccari, N.: Aquaro, donato: mechanical characterization of Li2TiO3 and Li4SiO4 pebble beds: experimental determination of the material properties and of the pebble bed effective values. Fusion Eng. Des. 82(15), 2375–2382 (2007)

Löbbecke, B., Knitter, R.: Procurement and quality control of Li\(_4\)SiO\(_4\) pebbles for testing of breeder unit mock-ups. Report on TW6-TTBB-006-D2, FZK Fusion (2007)

Zhao, S.: Multiscale modeling of thermomechanical properties of ceramic pebbles. Ph.D. Thesis, Karlsruhe Institute of Technology (2010)

Desu, R.K., Chaudhuri, P., Annabattula, R.K.: High temperature oedometric compression of Li2TiO3 pebble beds for Indian TBM. Fusion Eng. Des. 136, 945–949 (2018)

Annabattula, R.K., Kolb, M., Gan, Y., Rolli, R., Kamlah, M.: Size-dependent crush analysis of lithium orthosilicate pebbles. Fusion Sci. Technol. 66, 136–141 (2014)

Gan, Y., Kamlah, M., Reimann, J.: Computer simulation of packing structure in pebble beds. Fusion Eng. Des. 85(10–12), 1782–1787 (2010)

Desu, R.K., Annabattula, R.K.: Particle size effects on the contact force distribution in compacted polydisperse granular assemblies. Granul. Matter 21(2), 29 (2019)

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Desu, R.K., Gan, Y., Kamlah, M. et al. Compaction mechanics of a polydisperse crushable spherical granular assembly using discrete element method. Int J Adv Eng Sci Appl Math 13, 114–121 (2021). https://doi.org/10.1007/s12572-020-00282-6

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12572-020-00282-6