Abstract

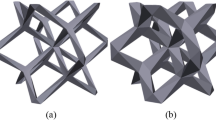

This paper compares the results of a theoretical approach, finite element analysis (FEA) and mechanical tests of monolithic TA6V Dode-Thin lattice core sandwich structures manufactured by powder bed laser beam melting process. An analytical approach to evaluate the mechanical properties of one Dode-Thin strut is briefly presented. The strut is then replaced by an equivalent beam whose cross-section is a solid circle. Various finite element (FE) models are used to calculate the effective mechanical properties of a defect-free structure and compared to the analytical results of beam theory. Besides the calculations, different experimental tests and measurements are carried out to measure the stiffness of the sandwich beams. These experiments show that both theoretical and numerical predictions significantly overestimate the stiffnesses. The discrepancies between the models and the as-built components are mainly due to geometrical imperfections and internal defects (porosity) caused by the AM process. Optical observations and X-ray computed tomography (CT) are then performed to determine the actual cross-sectional properties of the struts. Finally, this study provides the engineer with a simple method to replace a Dode-Thin strut with an equivalent beam of solid circular cross-section, and to define the equivalent 3D-orthotropic material with homogenized mechanical properties. Another contribution of this work is the insight into the as-built physical parameters to improve the correlation between models and experimental data.

Similar content being viewed by others

Abbreviations

- AM:

-

Additive manufacturing

- CAD:

-

Computer-aided design

- CT:

-

Computed tomography

- DIC:

-

Digital image correlation

- DMA:

-

Dynamic mechanical analysis

- DOF:

-

Degrees of freedom

- DT:

-

Dode-Thin

- FE:

-

Finite element

- FEA:

-

Finite element analysis

- FEM:

-

Finite element model

- FRF:

-

Frequency response function

- HSV:

-

Hue, saturation, lightness

- LBM:

-

Laser beam melting

- RD:

-

Rhombic dodecahedron

- SLM:

-

Selective laser melting

- ZOI:

-

Zone of interest

- i.e.:

-

Id est

- µCT:

-

Micro-computed tomography

- wrt:

-

With respect to

- a :

-

Length of the sides of the equilateral triangle

- A :

-

Cross-sectional area

- A eq :

-

Equivalent cross-sectional area

- D :

-

Diameter of the beam

- D eq :

-

Equivalent diameter of the beam

- E* :

-

Effective Young’s modulus of the lattice unit cell

- E S :

-

Young’s modulus of the solid material

- F :

-

Force

- F Y :

-

Force component about y-axis

- G* :

-

Effective shear modulus of the lattice unit cell

- G S :

-

Shear modulus of the solid material

- I :

-

Second-area moment, commonly referred to as moment of inertia

- I eq :

-

Equivalent moment of inertia

- K axial :

-

Axial stiffness

- L :

-

Length of the beam

- L Cell :

-

Edge length of the cube into which the lattice unit cell is inscribed

- M :

-

Bending moment

- N :

-

Normal force

- T :

-

Transverse shear force

- λ :

-

Relative position along the beam axis from origin

- ν*:

-

Effective Poisson’s ratio of the lattice unit cell

- ν S :

-

Poisson’s ratio of the solid material

- ρ S :

-

Density of the solid material

References

Nickels, L.: AM and aerospace: an ideal combination. Met. Powder Rep. 70(6), 300–303 (2015). https://doi.org/10.1016/j.mprp.2015.06.005

Bici, M., et al.: Development of a multifunctional panel for aerospace use through SLM additive manufacturing. Procedia CIRP 67(1), 215–220 (2018). https://doi.org/10.1016/j.procir.2017.12.202

Maconachie, T., et al.: SLM lattice structures: properties, performance, applications and challenges. Mater. Des. 183, 108137 (2019). https://doi.org/10.1016/j.matdes.2019.108137

Pommatau, G., et al.: Issues for Design, Modelling and Laser Beam Manufacturing of Structures Including Aluminium Lattices. In: Proceedings of 15th European Conference on Spacecraft Structures, Materials and Environmental Testing, Ecssmet 2018, Esa-Estec, Noordwijk, The Netherlands (2018)

Guy, Ph., et al.: Equivalent Beam Model for the Strut of a Lattice Dode-Thin Unit Cell, submitted (2023)

Yang, Y., et al.: Multiple strut-deformation patterns based analytical elastic modulus of sandwich BCC lattices. Mater. Des. 181, 107916 (2019). https://doi.org/10.1016/j.matdes.2019.107916

Ushijima, K., Cantwell, W.J., Chen, D.H.: Prediction of the mechanical properties of micro-lattice structures subjected to multi-axial loading. Int. J. Mech. Sci. 68, 47–55 (2013). https://doi.org/10.1016/j.ijmecsci.2012.12.017

Acknowledgements

The authors wish to acknowledge and convey their appreciation to those individuals, Erasmus+ students, institutions and corporations, in particular Thales Alenia Space—France (TAS-F) in Toulouse, who have generously given permission to use and study their TA6V lattice core sandwich structures fabricated by the laser beam melting (LBM) additive manufacturing technique. We also thank Dr. Paul Duru from FERMAT (Fluids, Energy, Reactors, Materials and Transfers) Research Federation in Toulouse for carrying out the X-ray micro-computed tomography of the sample.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Data availability

The data presented in this study is available on request.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Guy, P., Dorival, O., Pérez, M.A. et al. Investigations into the mechanical properties of TA6V Dode-Thin lattice sandwich beams fabricated by powder bed laser beam melting process. CEAS Space J (2024). https://doi.org/10.1007/s12567-024-00543-1

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12567-024-00543-1