Abstract

Purpose

This paper presents a method for optimising freight traffic procedures on the border between Slovakia (European Union) and Ukraine.

Background

In Eastern Europe a considerable volume of goods is usually carried by rail. On the Ukrainian side there is the Chop railway station, the largest entry/exit rail point and on the Slovakian side there is the Čierna nad Tisou railway station. The latter station is on the TEN-T as part of the Rhine-Danube Core Network Corridor. Total railway freight between Slovakia and Ukraine makes around 16 million tonnes per year, which amounts to about 40 % of the entire railway freight transport in Slovakia. The most frequently transported goods are iron, coal and metal. Around 247,000 freight cars are used for transport between Slovakia and Ukraine every year.

Methodology

The most important organisational aspect of transport in this case is the existence of two different procedures. In Slovakia, transport is organised according to the Convention concerning International Carriage by Rail (COTIF), and in Ukraine, transport is organised according to the Agreement on International Goods Transport by Rail (SMGS). Today all procedures are completely manual. This means that transport documentation is rewritten from SMGS to COTIF, or vice versa. This process is very labour-intensive and time-consuming. Following an analysis we performed a case study using the critical path method (CPM) for optimisation of the technological process for transport methodology at the Čierna nad Tisou railway station and we proposed a method for electronic data exchange between the rail and customs authorities of Slovakia and Ukraine.

Results

The research optimised organisational procedures by using the critical path method (CPM) and introducing electronic data exchange to cut down the whole process by 170 min or 66.7 % of the total time spent at the border station.

Conclusion

Railway freight transport has a very important role in Eastern Europe, but also in the European Union (EU), so to enable seamless connections there is a need to cut down the time that the freight/wagons spend at the border station. To meet the future demand for transport between the East and West there is a need to introduce electronic data exchange between COTIF and SMGS to achieve a quicker and easier use of freight railways for transport of goods.

Similar content being viewed by others

1 Introduction

Railway freight offers a quick, large-scale, safe transportation of goods over long distances in a reasonable period of time. In order to keep pace with road and sea transport, it is important to develop technical, technological and organisational aspects of this freight mode. The organisation of rail transport of goods between Slovakia and Ukraine is a demanding and time-consuming process requiring the cooperation and coordination of a large number of services to satisfy legal, technological, organisational and technical regulations.

During the transport of goods between Slovakia and Ukraine significant problems can arise Tarrova [19].

-

1)

A technical problem is presented by different track gauges (1435 mm in Slovakia, and 1520 mm in Ukraine).

-

2)

An organisational problem is posed by a different organisation of freight transport (CIM - Uniform Rules Concerning the Contract of International Carriage of Goods by Rail, and SMGS - The Agreement on International Goods Transport by Rail).

-

3)

Customs issues. Slovakia is in both the European Union (EU) and the Schengen Area. This means that goods going from Ukraine to Slovakia are not subject to any additional customs control within the European Union. Therefore, Slovakia represents a strategic control point for goods entering the EU. The Ukraine-EU Strategic Framework for Customs Cooperation is currently in force for goods transported between Ukraine and the EU.

In order to achieve competitiveness and coherence of international rail transport it is important to harmonise the Convention concerning International Carriage by Rail (COTIF) and the Organisation for Cooperation of Railways (OSJD). The OSJD was established to create and improve the coordination of international rail transport, especially transport between Europe and Asia Knížka [15]. The Convention concerning International Carriage by Rail was convened in Bern on 9 May 1980, and entered into force on 1 May 1985. This agreement brings together 49 members and one associate member state (http://www.otif.org/en/about-otif/list-of-member-states.html) of the Intergovernmental Organisation for International Carriage by Rail (OTIF). Its mission is to create a uniform legal framework for the carriage of passengers, baggage and goods within the member states (http://www.otif.org/index.php?L=2).

Network techniques are often used in technological processes of optimisation that contain many interrelated activities. One approach that has been widely used is the critical path method, in which a network diagram depicts activities ranked in order of precedence. This method also calculates their starting, float, and finishing times to identify critical activities, and it constructs a time chart to display possible project schedules. Critical path method (CPM) was developed by the DuPont Company in 1957 Pašagić [16].

The focus of this research is on organisational problems in different procedures, such as CIM and SMGS. The paper is organised as follows: Section 2 provides a literature review on international freight transport, Section 3 gives an analysis of traffic between Slovakia and Ukraine, Section 4 describes differences between transport conditions for CIM and SMGS procedures, Section 5 constitutes a case study of the border station Čierna nad Tisou, and Section 6 provides a conclusion. Section 2 offers a critical overview of the most important scientific research in the field of international freight transport, especially that one which attempts to resolve organisational problems. In Section 3 we provide analyses of railway traffic flows between Slovakia and neighbouring countries and between Slovakia and Ukraine. In Section 4 we tackle the organisational problem of different conditions between CIM and SMGS procedures. In Section 5 we propose a new technological process to resolve organisational differences between CIM and SMGS. To identify an optimal solution we use CPM network techniques. In Section 6 we give an overview of our research steps and point out the most important results.

2 Literature review on international freight transport

International railway transport is crucial for a country’s as well as a region’s economy, so a huge amount of research investigates the role and the function of international railway transport and regional economy. In this section we review the most important research on the organisation of international railway freight transport. A comprehensive review is given by Ben Akiva et al. [3], who divided freight transport into three categories: (1) global (international), (2) regional, and (3) local (urban). The global (international) category identifies two factors crucial for organising railway freight transport. The first one is the relation between economy and freight transport, and the second one is a dynamic optimisation with a game theory approach. Tavasszy and De Jong [20] examined key issues to do with modelling freight transport; one of the most important aspects in freight transport is a demand modelling. Afterwards a research of freight generation connected with freight trip generation models and flow by distribution problems in freight transport was conducted. An excellent case study of freight trip generation in the New York City Metropolitan Area is provided. Rich et al. [18] introduced a weighted logit freight mode-choice model. They found a way to establish suitable decoupling of agents and shipments and determined transport demand elasticities with respect to monetary cost and travel time. Crisalli et al. [6] investigated the connection between rail and road freight policy for long-distance freight transport with an emphasis on freight demand. Islam and Eidhammer [11] explored Pan-European and international rail freight services. Other recent examples of such a research include CREAM [5], RETRACK [17], Islam et al. [14] and Islam et al. [13]. The CREAM [5] study, co-funded by the European Commission within the Sixth Framework Programme, contained a number of technological and operational research and development activities identified by the stakeholders, who comprised rail infrastructure operators, railway operators, intermodal operators and their customers. The CREAM study claims credit for a substantial increase in rail freight transport on this important East–west freight corridor which contributed to the EU transport policy goals. The RETRACK [17] study, co-funded by the European Commission within the Sixth Framework Programme, aimed to contribute to the Commission’s aspirations of a modal shift of freight traffic from road to rail with a market share of 15 % by 2020 to achieve a commercial viability and contribute to sustainable mobility. Islam et al. [13] conducted research to determine future (2030 and 2050) fleet size and found, among others, that significantly more rolling stock (in particular flat wagons, covered wagons and covered hopper wagons) as well as improved asset utilisation would be vital to facilitate the transport of increased freight volume as required in the EU Transport White Paper 2011 European Commission [8]. Another important aspect of international railway freight transport was examined by Islam et al. [14]. They established six key performance indicators (KPI) in transport chains: (1) transport cost, (2) transport time, (3) flexibility, (4) reliability, (5) quality, and (6) sustainability. Biškup [4] conducted research on the organisation of international freight transport between the European Union countries and Ukraine. He established main indicators that produced bottlenecks on the borders. He points out that technical problems have been eliminated or significantly reduced over the years but organisational and technological issues still need to be addressed in the interest of time and cost savings at border stationsIslam et al. [12] looked at the impact of EU transport in a White Paper in rail freight demand forecast. They suggested that demand for railway freight transport would grow significantly, especially when considering the high scenarios, that is very optimistic, but possibly there exists a necessitating investment in technologies, infrastructure and terminals so that the railway sector would be able to increase productivity significantly.

In this part we concentrate on research that focuses on organisational and technological procedures in international railway transport. Evtimov [9] suggested that there should be interoperability between CIM and SMGS procedures, and identified three phases: (1) a common CIM/SMGS consignment note, (2) a unique claim handling mechanism, and (3) a single Eurasian rail transport law. Zitrický [23] investigated the rationalisation of technological processes in international railway freight transport using network optimising methods such as the program evaluation and review technique (PERT) and the critical path method (CPM). His main focus was on how to reduce the time spent by technological processes. Abramović [1] examined the use of demand forecasting models in international freight transport. Through these models he established not only the influence of the traffic sector but also the key drivers of the economy. Zitrický and Blaho [24] suggested technical and technological parameters for use with the common consignment note CIM/SMGS. In research Drożdziel et al. [7] make a proposal of solving the problems within the East – West transport by building a new broad gauge infrastructure, but they did not make any analyses for organisational optimisation in transport between the East and West. In our research we have used following resources about network techniques modelling: Pašagić [16] and Tulsian and Pandey [21]. Both resources take a strict mathematical approach for explaining network techniques. But Pašagić [16] has also introduced some possible uses of network techniques in transport.

3 Analysis of traffic between Slovakia and Ukraine

Trade within the European Union member countries and with external countries offers to states a chance to prepare for multilateral and bilateral negotiations within the common commercial policy and to evaluate the progress of the common market and the integration of European economies. Merchandise trade is an important source of information for the balance of payments, national accounts and short-term and long-term statistics.

The majority of freight traffic entering Slovakia from Ukraine employs the Čierna nad Tisou and Maťovce railway stations. The Čierna nad Tisou station is on the TENT-T corridor as part of the Rhine-Danube Core Network Corridor, and Maťovce railway station is on the wide gauge track 104 from Uzhhorod to Košice, which is connected by track 103 to the TEN-T corridor. ZSSK Cargo, a national cargo carrier in Slovakia, is responsible for wagon shipments, intermodal (containerised cargo) units, car transportation and trans-shipment services in eastern Slovakia’s trans-shipment yards (ESTY). Figure 1 illustrates the volume and proportion of cargo flows between ZSSK Cargo and neighbouring railway administrations in 2012.

Trade flows between ZSSK cargo and neighbouring railway administrations. Source: http://www.zscargo.sk/files/brozury/vseobecna-brozura-aj-ru_2013_full.pdf [25]

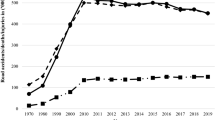

Iron ore (see Fig. 2) is the most common goods type carried by ZSSK Cargo, and its highest point was reached in 2006 when 15,235,000 tonnes were transported. Most freight traffic consisted of the following: metal products totalling 8,374,000 tonnes were transported in 2007; 8,652,000 tonnes of coal were transported in 2005; 5,160,000 tonnes of building materials were transported in 2006; 3,515,000 tonnes of petroleum products were transported in 2007; 3,517,000 tonnes of wood were transported in 2005; 3,759,000 tonnes of chemical products were transported in 2005; 2,280,000 tonnes of intermodal goods were transported in 2008; 1,577,000 tonnes of undefined goods were transported in 2006; and 1,288,000 tonnes of food were transported in 2005. Figure 2 illustrates the relationship of certain goods in the period from 2005 to 2012.

Volume development by individual commodities from 2005 to 2012. Source: http://www.zscargo.sk/files/dokumenty/2013/statisticka-rocenka_2012_en_nahlad.pdf [26]

Most goods were transported across the Čierna nad Tisou and Maťovce border stations in 2006 from the direction of Ukraine. They accounted for 17,342,721 tonnes and 269,329 wagons. Thereafter there was a drop in goods transported in 2012: 14,995,719 tonnes of cargo and 231,214 wagons. The first reason for the decreased volume of transport was the world financial crisis which started in 2008. Because of the financial crisis industrial production was highly restricted which was reflected in the volume of transport. Another very important factor was the political situation between Russia and Ukraine which affected shipments from Russia to the European Union. In the last few years shippers have made an active search for alternative transport routes. One such alternative route is through Belarus, bypassing Slovakia. Table 1 illustrates the entry of goods from Ukraine to Slovakia through the Čierna nad Tisou and Maťovce border crossings.

Most goods were transported across the Čierna nad Tisou and Maťovce border stations in 2005 from the direction of Slovakia and accounted for 1,849,387 tonnes and 50,033 wagons. Over the years the amount of export goods from Slovakia to Ukraine has decreased and in 2012 some 586,933 tonnes of goods and 17,163 wagons were transported. Table 2 shows the entry of goods through the Maťovce and Čierna nad Tisou stations from Slovakia to Ukraine.

Previous data analyses of traffic flows show the importance of Čierna nad Tisou as a border crossing station. For example, traffic volume with Ukraine is a one-third of the total volume of goods transported by ZSSK Cargo (Slovakia’s biggest freight railway undertaking), and if an alternative route were to be found it would mean huge problems not only for freight undertakings but also for railway infrastructure managers in Slovakia. Therefore it is necessary to optimise technological services in border stations because we need to minimise the time trains spend there. Of course, all factors which influence this situation (customs, transport laws, technical problems, reloading of goods) must also be taken into account. For example, when goods are at a station waiting for reloading or are delayed by customs, their owner suffers financial lost. We can conclude that faster transport would cut costs for all stakeholders in the transport chain: infrastructure managers, railway undertakings, owners of goods, customers, etc.

4 Differences between transport conditions for CIM and SMGS procedures

International rail traffic begins in the territory of one country and ends in the territory of another one, i.e., it spans the territory of at least two countries. International agreements and the resulting regulations related to international carriage by rail include the Convention concerning International Carriage by Rail (COTIF) and the Warsaw agreements (SMGS, SMPS).

The transport of goods in international rail freight transport is regulated by the Convention on International Carriage by Rail (COTIF) dated 1 January 2001, COTIF 1999, Appendix B - Uniform Rules concerning the Contract of International Carriage of Goods by rail (CIM) and implementing international railway regulations, pursuant to which users of transport and railway workers or railway employees alone are to act. This contract defines the rules for transport of goods between rail carriers and users. The purpose of the contract is to establish responsibility for the organisation of transport, establish obligations to be met by the carrier and the user, create a unified tariff system to prevent a monopoly, and ensure a transparent railway market is available to all on equal terms. The CIM is in accordance with competition requirements under Articles 100 to 108 of the EU Consolidated Treaty. The contract of carriage shall be determined by the consignment note that is signed and confirmed by the carrier and the consignee. Acceptance of goods is confirmed in two copies of the consignment note, with the recipient receiving a duplicate of the consignment note as a proof of accepting the goods. A consignment note is issued for each shipment. Table 3 shows sheets names and users of each sheet of CIM consignment note. The consignor and the carrier are to agree the transit period. The maximum transit period is as follows:

-

a)

for wagon-load consignments

-

period for consignment = 12 h,

-

period for carriage, for each 400 km = 24 h;

-

-

b)

for less than wagon-load consignments

-

period for consignment = 24 h,

-

period for carriage, for each 400 km = 24 h.

-

According to the SMGS agreement on carriage of goods, having an SMGS consignment note gives a railway administration that is a party to the SMGS Agreement a direct transport passage through all the stations to the destination station. Table 4 shows sheets names and users of each sheet of SMGS consignment note.

The delivery times in SMGS are:

-

period for consignment = 1 day;

-

period for carriage:

-

wagon loads for each 200 tariff kilometres = 1 day,

-

large container loads for each 150 tariff kilometres = 1 day.

-

We can determine a difference between number of sheets between CIM and SMGS consignment note and also a difference between the delivery times between transport rules of CIM and SMGS. Except for differences in delivery times and structures of the consignment notes there are other differences between CIM and SMGS in terms of transport law. For example, there are differences in the responsibility for a loss or damage of goods, and in the compensation if the delivery time is exceeded. Based on the transport conditions of CIM maximum of compensation is four times the carriage charge (article 33 of CIM). Transport rules of SMGS grade compensation according to delay time (article 45 of SMGS):

-

6 % carriage charge for exceeding the delivery times by up to 1/10

-

18 % carriage charge for exceeding the delivery times by 1/10 up to 3/10

-

30 % carriage charge for exceeding the delivery times by more than 3/10

Disparity also exists in the application of the Berne Convention (CIM) and the Warsaw Pact (SMGS) in the case of the use of wagons. CIM makes use of the AVV agreement and SMGS makes use of the PGV agreement. These agreements apply different rules. Last but not least, there is also a difference in the case of payment of fees for the use of railway infrastructure in countries which use CIM or SMGS.

The transport rules of CIM and SMGS help to better organise transport processes in international rail freight transport and they harmonise conditions for quick, quality and safe international rail freight transport. Establishing the advantages and disadvantages of the transport rules of CIM and SMGS is a complicated process which is affected by several factors. For example, Belarus, the Russian Federation and Kazakhstan have common customs areas and for these countries and their railway companies SMGS transport rules are preferable. In the Slovak Republic it is more convenient to use CIM transport rules based on the membership in the EU. One of great advantages of CIM rules is that the consignment note can be used as a customs paper in rail transport. When a carrier uses CIM consignment note for import or export to/from the EU there is no need to make an additional customs document. With the SMGS consignment note this option does not exist and the carrier (or shipper) must create a transit declaration based on the Union Customs Code (http://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32013R0952&from=EN) [22].

The International Committee of the Railway and the Organisation for Cooperation of Railways is working on the implementation of legal frameworks to enable simpler, more acceptable and faster transport of goods by rail. A unique CIM/SMGS consignment note is to be created. For example, transport through the Slovak Railways is to be regulated by the rules of the CIM until the border station, where the rules concerning SMGS for the further transport path in Ukraine will be applied, and vice versa. Benefits of a CIM/SMGS consignment note include the following: both the contracts of carriage can be displayed on a single sheet of paper that can be issued in an electronic form, with greater legal certainty for all participants in the process of transportation, reduced transportation costs, reduced transport time, improved quality of transport, and greater competitiveness of railways in international freight.

5 Case study: analysis of the Čierna nad Tisou border station

Connection of two direct transport regimes (CIM/SMGS) in Čierna nad Tisou on different railway gauges has to respect both the border of the Schengen Area and the EU policy. The transfer of goods by rail in Čierna nad Tisou is realised by international transport policy and railways must respect their conditions.

Technological activities on the cross-border station of Čierna nad Tisou can be represented as an acyclic edge-oriented network graph. This graph defines the start and the end of the technological process. All activities are interdependent and they have their own rules. Every factor which influences technological work at the cross-border station of Čierna nad Tisou must be reflected in a network graph.

While optimising operations of trains we work on the presumption that double-exchange crossing stations, or common interchange station, are utilised.

The technological graph reflects the following actions:

-

border and customs control,

-

control of train inventory and train documentation,

-

manipulation of transport documents between necessary subjects,

-

transport inspection of train,

-

phytosanitary and veterinary control of train, and

-

shunting work by train.

In the following sections we will elaborate our methodology and use of a network graph for freight transport between the Slovak Republic and Ukraine at the border station of Čierna nad Tisou.

5.1 Methodological approach to case study

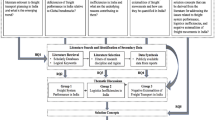

In our study, we used a model of eight steps: (1) data collection, (2) analysis of a current organisational process, (3) technological graph process, (4) using CPM and determining bottlenecks, (5) proposal of an improved organisational process, (6) new technological graph process, (7) comparative analysis between a current and proposed organisational process, and (8) conclusions and recommendations.

The first step was the most sensitive because without excellent data it is very difficult to take the second step of a current situation analysis. After analysis of the current organisational process we made a technological graph, so that in the next step we could use the critical path method to determine bottlenecks in the organisational process. The next step was the proposal of an improved organisational process. To be confident of advantages and disadvantages of that new organisational process we again made a technological graph and used the critical path method. In this stage we conducted a comparative analysis between the current and the proposed organisational process. The last step was to formulate conclusions and recommendations for introducing the new organisational process. Figure 3 shows a scheme of research methodology approach for the case study.

5.2 A short overview of Critical Path Method (CPM)

First of all we made a graph of the technological processes at the cross-border station of Čierna nad Tisou. A network graph based on the analysis of technological activities when trains cross the border between Slovakia and Ukraine was required.

Then we applied the CPM method:

-

to determine activities and their earliest start TMi, in all vertices and to determine minimal time of activity tij, which is equal to the earliest possible start of operations of the end vertices (tn = TMe)

-

to determine activities and their latest start TPi, in all vertices and to determine the critical path

-

to conduct analysis and identify reallocation reserves in the graph

Before searching for the critical path solution in the network graph it is necessary to show (Fig. 4) the normalised definition of vertices (V) and edges (E) such as it is used in the CPM method.

5.2.1 Determination of the earliest start of activities

The initial vertex V1 is a value of the earliest start of activity TM1 = 0. The next vertices have a value that is calculated based on the formula 1 and the graphical representation is shown in the Fig. 5.

If vertex j enters more activities (Fig. 6), the value of the latest start of activity in vertex j is the maximum of the sum in the formula 2.

In the formula 2 there exists a simple rule: all activities which exit from a vertex can start after the end of all activities which enter a vertex. This rule is applied across all vertices in the graph until the end vertex Ve. The value of the earliest start of activity in Vertex Ve is the minimal time of the project (modelling process). The minimal time of the project ensures the realisation of all activities in the project (process) – this is the algorithm of the longest path in the oriented graph.

All procedures are shown on the network graph in the Fig. 7, where the time duration of all activities tij can be located directly (shown by the edges in the squares). After application of the above-mentioned rules we find the times of the earliest start in all vertices until the end vertex. The value of the earliest start in the end vertex is TM9 equals 34. This value is also the minimal time of the whole project (modelling process).

5.2.2 Determination of the last start of activities and the critical path

To determine the last start of activities in vertices we started with the end vertex, in which we assigned the value of the time duration of project (modelling process) – Tn. This is shown in the formula 3.

Then we determined times of the latest start of activities in all vertices as follows:

-

if only one activity (one edge) exits from vertex i as in the Fig. 8 we determine values based on the formula 4.

$$ {\mathrm{TP}}_{\mathrm{i}}={\mathrm{TP}}_{\mathrm{j}}\hbox{--} {\mathrm{t}}_{\mathrm{i}\mathrm{j}} $$(4) -

if more activities exit from vertex i (Fig. 9) we determine the value of the latest start of activities by the formula 5.

$$ T{P}_i= min\ \left(T{P}_j\hbox{--} {t}_{ij}\right) $$(5)

Formula 6 shows that the earliest start of activities must be set so as not to endanger the project (modelling process) deadline. We continued using the above mentioned method until the start vertex V1 is calculated based on the formula 6; and also formula 6 serves as a proof of accuracy.

Subsequently it is possible to determine the critical path in the network graph. The critical path connects the vertices, which have the same value as the earliest and the latest start (TPi = TMi). Vertices with zero difference are connected, because these activities have no critical reserve and any delay could extend the project (modelling process).

If we apply these steps of the CPM method to the example which is presented in the Fig. 7, we obtain a value of the latest start of activity in all vertices and we can calculate the critical path, which begins in the start vertex V1 and continues across the vertices V4, V5, V6 and V8 until the end vertex V9. The critical path is formed by edges (activities) (1–4), (4–5), (5–6), (6–8) and (8–9). It is obvious that the sum of durations is equal to the duration of the event. The result is shown in the Fig. 10.

5.3 Technological graph for incoming trains: present situation

The set of vertices of technological practices of an incoming train \( V=\left({V}_1\dots {V}_n\right) \) includes the activities for safe, quick and regular transfer of goods at the border crossing.

The set of vertices of the network graph \( {G}_1\left(V,E\right) \) for the analysis of the operating activities of incoming trains to the border station consists of the following technological activities (Fig. 11):

-

the regulations resulting from administrative formalities:

-

customs inspection of accompanying documents, and

-

veterinary and phytosanitary control.

-

-

work with accompanying documents:

-

train inventory check,

-

approval of the consignment notes (CN),

-

execution of wagon stickers (for reloading),

-

taping the wagons, and

-

preparing the documentation for customs office.

-

-

technical inspection,

-

transport inspection, and

-

shunting work.

Below the graph in the Fig. 11 there are listed specific technological activities. These activities formed the individual vertices.

5.4 Searching the critical path using the CPM method

A network graph represents a tool from Graph theory that allows a search for the critical path of processes by using the CPM method.

After the creation of a network graph of technological processes of the incoming train \( {G}_1 \) it is possible to search for a solution using the critical path method.

Single activities in the technological process of incoming trains are identified by analysis of the border station of Čierna nad Tisou.

The resulting critical path determines the earliest possible start and the latest possible end. A critical path of the technological process is shown in the Fig. 12.

The critical path consists of these activities:

-

start of process

-

technical inspection

-

execution of wagon stickers

-

taping the wagons

-

preparing the documentation for customs office

-

transport inspection

-

customs control of documentation

-

ending operation

5.5 Technological graph for incoming trains: proposed situation

The critical path of graph G1 identifies critical activities of the technological process of an incoming train to Čierna nad Tisou.

The process can be shortened after the reorganisation of technological operations. This depends on information systems and their level of application. Another option how to reduce time of a technological process is to use the common consignment note CIM/SMGS in an electronic form. In Čierna nad Tisou more than 90 % of shipments still crosses the border with the SMGS classical consignment note. This means that it is necessary to use a completely manual rewriting from the SMGS consignment note to a CIM consignment note. This operation is not only time-consuming but it is frequently error-ridden. Each such error increases transport costs.

Rationalisation measures of the technological process of the incoming train are:

-

electronic processing of transition documentation before the train arrives at the border station,

-

creating the wagon label before the train arrives at the border station, and

-

using an electronic form of customs clearance.

The proposal for a new technological process for incoming trains at the border station is shown on the graph \( {G}_2\left(V,E\right) \) (Fig. 13). The graph contains necessary technological operations which are needed for the train to enter the EU and/or the Schengen Area.

Because of the rules for acceptance of rolling stock in international transport the technical inspection is necessary. But also due to change in transport regime there is a need for the cooperation of both railway companies. In the case of technical errors of a wagon the railway undertakings discard the wagon from the train. After taping the wagons it is possible to allocate the wagons to reloading places.

Transport inspection of consignments is based on the use of information systems, and conveys information about trains and consignments before their arrival at the border station, making this operation more efficient and shorter.

Preparing the documentation for the customs office is not required, because thanks to the information system it can be prepared much earlier. This operation accelerates the whole technological operation.

According to the technological process the transport inspection is the last operation with incoming trains in the border station Čierna nad Tisou.

Graph \( {G}_2\left(\mathrm{V},\mathrm{E}\right) \) shows the critical path (Fig. 14). Critical operations are:

-

transport inspection, and

-

ending operations.

6 Conclusion

Organisation of the rail transport of goods between Slovakia and Ukraine is a demanding and time-consuming process requiring the cooperation and coordination of all services to observe legal, technological, organisational and technical regulations. Establishing a common CIM/SMGS consignment note is a key goal in the implementation of fast, efficient and safe transportation of goods between the European Union and Ukraine. The introduction of a common CIM/SMGS consignment note will contribute to a greater legal certainty for all participants in the process of transportation of cargo in international traffic. Moreover the time of freight transport will be reduced, thus contributing to a reduction in transport costs and an improved quality of transport. Failings in electronic data processing of CIM and SMGS consignment notes greatly extend the processing time of transport documentation, leading to increased transportation costs. In the interests of offering customers a simpler method for organising transport between member states signatories to the CIM and SMGS, contract work to improve existing rules and introduction of new technical and technological innovations are needed. It is necessary to introduce an electronic information system that will enable the electronic processing of transport documents or electronic CIM/SMGS consignment notes. The system must be compatible with the system of the countries participating in the implementation of rail freight transport between Slovakia and Ukraine so as to accelerate the process of checking and issuing the documentation required when goods move from Ukraine to Slovakia, and vice versa. Electronic processing of transport documentation offers a flexible and efficient service with the information available in real time among all participants involved in the process of transporting goods by rail. The introduction of electronic processing of transport documents reduces the technological processing time for handling the wagons, speeds up the transport process and increases the efficiency of employees. According to the case study, if electronic waybills were to be applied, this would equate to a saving of 170 min or 66.7 % of the total time spent at border stations.

References

Abramović B (2010) Modeliranje potražnje u funkciji prijevoza željeznicom (Demand Modelling of Functions of Railway Transport - in Croatian), PhD Thesis, University of Zagreb Faculty of Traffic and Transport Sciences, Zagreb

Agreement on International Goods Transport by Rail - SMGS, http://osjd.org/doco/public/ru?STRUCTURE_ID=5038, Retrieved 8 October 2015

Ben Akiva M, Meersman H, Van de Voorde E (eds) (2013) Freight transport modelling. Emerald Group Publishing Limited, Bingley, ISBN 978-1-78190-285-1

Biškup V (2014) Organizacija željezničkog prijevoza između Europske unije i Republike Ukrajine (Organization of Railway Transport between the European Union and Ukraine - in Croatian), Master thesis, University of Zagreb Faculty of Traffic and Transport Sciences, Zagreb

CREAM (2012) Final Report. The CREAM Project – ‘Customer-driven rail-freight services on a European mega-corridor based on advanced business and operating models’, Technical and operational innovations implemented on a European rail freight corridor, HaCon Ingenieurgesellschaft Gmbh, 30163 Hannover, Germany, from http://www.creamproject.eu/home/index.php, Retrieved 9 February 2016

Crisalli U, Comi A, Rosati L (2013) A methodology for the assessment of rail-road freight transport policies. In Procedia - social and behavioural sciences 87, doi:10.1016/j.sbspro.2013.10.611, Elsevier Ltd, 292–305

Drożdziel P, Buková B, Brumerčíková E (2015) Prospect of international freight transport in the East - West direction. Transp Probl 10(4):1896–0596

European Commission (2011) WHITE PAPER – Roadmap to a Single European Transport Area – Towards a competitive and resource efficient transport system, Brussels, 28.3.2011, COM(2011) 144 final

Evtimov E (2009) Interoperability CIM and SMGS. In: e-Freight Conference Brussels, 17 February 2009, http://www.euro-case.org/documents/EVTIMOV.pdf, Retrieved 8 October 2015

HŽ Cargo Priručnik o CIM-ovu teretnom listu (GLV-CIM) (Handbook for CIM consignment note), http://www.hzcargo.hr/UserDocsImages/150a%20-%20Priru%C4%8Dnik%20o%20CIM-ovu%20teretnom%20listu%20(GLV-CIM),(stanje%20od%201.7.2016.).pdf, Retrieved 8 October 2015

Islam DMZ, Eidhammer O (2015) Advances in the competitiveness of pan-European rail freight services: findings from a case study. R&D Manag. doi:10.1111/radm.12135

Islam DMZ, Jackson R, Zunder TH, Burgess A (2015) Assessing the impact of the 2011 EU Transport White Paper - a rail freight demand forecast up to 2050 for the EU27. Eur Transp Res Rev 7(3):1–9. doi:10.1007/s12544-015-0171-7

Islam DMZ, Jackson R, Robinson M (2015) European freight rolling stock fleet size in 2050 in light of the transport white paper 2011. J Rail Transp Plann Manag 5(4):195––210. doi:10.1016/j.jrtpm.2015.09.001

Islam DMZ, Zunder TH, Jorna R (2013) Performance evaluation of an online benchmarking tool for European freight transport chains. BIJ 20(2):233–250

Knížka J (2006) Medzinárodná železničná preprava (International railway transport). Edis, Žilina, ISBN 80-8070-638-7

Pašagić H (1998) Matematičko modeliranje i teorija grafova (Mathematical modelling and graph theory - in the Croatian language). University of Zagreb Faculty of Traffic and Transport Sciences, Zagreb, ISBN 953-6221-69-1

RETRACK (2012) The RETRACK Project – ‘Reorganization of Transport Networks by advanced Rail freight Concepts’, Final Report, November, TNO, Delft, NL, project website http://www.retrack.eu/, Retrieved 9 February 2016

Rich J, Holmbland PM, Hansen CO (2009) A weighted logit freight mode-choice model. Transportation Research Part E, 45, Elsevier, 1006–1019

Tarrova L (2013) Návrh na zlepšenie kontrolných služieb a prepravno - obstarávateľských činností v sekcii Východoslovenské prekladiská (The proposal of measures to improve control and shipping services of the East-Slovakian reloading station – in the Slovak language), Diploma thesis, University of Žilina Faculty of operation and economics of transport and communications, Žilina

Tavasszy L, De Jong G (eds) (2014) Modelling freight transport. Elsevier, Oxford

Tulsian PC, Pandey V (2006) Quantitative techniques: theory and problems. Pearson Education, India, ISBN 978-81-317-0186-7

Union Custom Code, http://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32013R0952&from=EN, Retrieved 9 February 2016

Zitrický V (2010) Racionalizácia technologických procesov v medzinárodnej železničnej doprave (Rationalization of Technological Process in International Railway Traffic - in the Slovak language), PhD Thesis, University of Žilina, Faculty of Operation and Economics of Transport and Communications, Žilina

Zitrický V, Blaho P (2011) Using of common consignment note CIM/SMGS in international railway transport, 12th International Scientific Conference LOGI 2011, Pardubice

ZSSK Cargo General Information, http://www.zscargo.sk/files/brozury/vseobecna-brozura-aj-ru_2013_full.pdf, Retrieved 9 February 2016

ZSSK Cargo Statistical Yearbook 2012, http://www.zscargo.sk/files/dokumenty/2013/statisticka-rocenka_2012_en_nahlad.pdf, Retrieved 9 February 2016

Author information

Authors and Affiliations

Corresponding author

Additional information

This article is part of Topical Collection on The Future of rail freight transport and logistics

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Abramović, B., Zitricky, V. & Biškup, V. Organisation of railway freight transport: case study CIM/SMGS between Slovakia and Ukraine. Eur. Transp. Res. Rev. 8, 27 (2016). https://doi.org/10.1007/s12544-016-0215-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12544-016-0215-7