Abstract

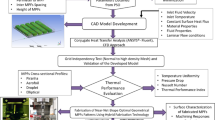

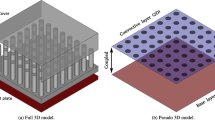

In this work, evaluation of thermal losses formulated on the “Entropy Generation Minimization” (EGM) approach is performed to design arrayed micro pin–fin (MPF) heat sinks. The thermodynamic approach primarily evaluates the effects of different thermal parameters: thermal resistance, pressure drop, Nusselt number, etc. The objective function in the EGM is formulated using the search-based Particle swarm optimization (PSO) algorithm on MATLAB® to optimize the dimensional parameters of the MPFs. The characteristic length, height, inter-MPF gaps, cross-sectional area, perimeter, and density of the MPFs are considered decisive design parameters for geometrical Optimization in inline and staggered patterns. The PSO code has run for 1000 iterations at optimal operating parameters. Eventually, the staggered pattern of the arrayed heat sink showed a prospective reduction in design parametric values over the inline pattern for constant heat sink volume and thermal loading conditions. The optimal design parameters are used to model various unconventional cross-sectional profiles, viz. elliptical, aerofoil, droplet, and piranha, of MPFs for numerical simulations. The manufacturing feasibility of the optimized profile of the MPFs heat sink is explored and verified for near-net-shape fabrication using a popular and novel microfabrication technology, presented in Part II of the work.

Similar content being viewed by others

References

Lee, S. H., & Lee, S. (2022). Fabrication of comb-structured acceleration sensors by roll-to-roll gravure printing. International Journal of Precision Engineering and Manufacturing-Green Technology, 9, 409–420. https://doi.org/10.1007/s40684-021-00342-7

Woodcock, C., Ng’oma, C., Sweet, M., Wang, Y., Peles, Y., & Plawsky, J. (2019). Ultra-high heat flux dissipation with Piranha Pin Fins. International Journal of Heat and Mass Transfer, 128, 504–515. https://doi.org/10.1016/j.ijheatmasstransfer.2018.09.030

Saraf, G., & Nirala, C. K. (2023). Novel texture pattern on WC inserts fabricated using reverse-μEDM for enhanced cutting of Ti6Al4V. Manufacturing Letters, 36, 72–75. https://doi.org/10.1016/j.mfglet.2023.04.001

Claude Sarno. (2001). Retrieved 18 Nov 2022 from https://www.electronics-cooling.com/2001/11/thermal-management-of-highly-integrated-electronic-packages-in-avionics-applications/

Tuckerman, D.B., Pease, R. F. W. (1981). Ultrahigh thermal conductance microstructures for cooling integrated circuits. In Proceedings 32nd Electronics Components Conference, San Diego, CA, May 10–12, IEEE, pp. 145–149.

Pragana, J. P. M., Bragança, I. M. F., Silva, C. M. A., & Martins, P. A. F. (2023). Hybrid wire-arc additive manufacturing of conformal cooling channels: A feasibility study. International Journal of Precision Engineering and Manufacturing-Green Technology, 10, 45–57. https://doi.org/10.1007/s40684-022-00436-w

Kim, S. H., Ahn, B. H., Ha, J. M., Young, S. A., & Beyong, K. C. (2016). Structural and vibration analysis considering the flow velocity of the heat exchanger. International Journal of Precision Engineering and Manufacturing, 17, 725–732. https://doi.org/10.1007/s12541-016-0090-0

Xia, G., Chen, Z., Cheng, L., Ma, D., Zhai, Y., & Yang, Y. (2017). Micro-PIV visualization and numerical simulation of flow and heat transfer in three micro Pin–fin heat sinks. International Journal of Thermal Sciences, 119, 9–23. https://doi.org/10.1016/j.ijthermalsci.2017.05.015

Gao, X., & Li, R. (2019). Spray impingement cooling: The state of the art. Advanced Cooling Technologies and Applications. https://doi.org/10.5772/intechopen.80256

Qiu, Y., Hu, W., Wu, C., & Chen, W. (2020). An experimental study of microchannel and micro- Pin–fin based on-chip cooling systems with silicon-to-silicon direct bonding. Sensors, 20, 1–14. https://doi.org/10.3390/s20195533

Chiu, H. C., Hsieh, R. H., Wang, K., Jang, J. H., & Yu, C. R. (2017). The heat transfer characteristics of liquid cooling heat sink with micro pin fins. International Communications in Heat and Mass Transfer, 86, 174–180. https://doi.org/10.1016/j.icheatmasstransfer.2017.05.027

Zhao, J., Huang, S., Gong, L., & Huang, Z. (2016). Numerical study and optimizing on micro square Pin–fin heat sink for electronic cooling. Applied Thermal Engineering, 93, 1347–1359. https://doi.org/10.1016/j.applthermaleng.2015.08.105

Koşar, A., & Peles, Y. (2007). TCPT-2006-096.R2: Micro scale pin fin heat sinks - Parametric performance evaluation study. IEEE Transactions on Components and Packaging Technologies, 30, 855–865. https://doi.org/10.1109/TCAPT.2007.906334

Wan, Z., & Joshi, Y. (2017). Pressure drop and heat transfer characteristics of pin fin enhanced microgaps in single phase microfluidic cooling. International Journal of Heat and Mass Transfer., 115, 115–126. https://doi.org/10.1016/j.ijheatmasstransfer.2017.06.117

Chen, S. T., & Huang, L. W. (2022). A micro-energy w-EDM power source based on high-frequency spark erosion for making diamond heat-sink arrays. International Journal of Precision Engineering and Manufacturing-Green Technology, 9, 1267–1283. https://doi.org/10.1007/s40684-021-00396-7

Tullius, J. F., Tullius, T. K., & Bayazitoglu, Y. (2012). Optimization of short micro pin fins in minichannels. International Journal of Heat and Mass Transfer, 55, 3921–3932. https://doi.org/10.1016/j.ijheatmasstransfer.2012.03.022

Gupta, D., Saha, P., & Roy, S. (2021). Computational analysis of perforation effect on the thermo-hydraulic performance of micro Pin–fin heat sink. International Journal of Thermal Sciences, 163, 106857. https://doi.org/10.1016/j.ijthermalsci.2021.106857

Ndao, S., Peles, Y., & Jensen, M. K. (2009). Multi-objective thermal design optimization and comparative analysis of electronics cooling technologies. International Journal of Heat and Mass Transfer, 52, 4317–4326. https://doi.org/10.1016/j.ijheatmasstransfer.2009.03.069

Bello-Ochende, T., Meyer, J. P., & Ighalo, F. U. (2010). Combined numerical Optimization and constructal theory for the design of microchannel heat sinks. Numerical Heat Transfer Part A: Applications, 58, 882–899. https://doi.org/10.1080/10407782.2010.529036

Normah, G. M., Oh, J. T., Nguyen, B. C., Il Choi, K., & Robiah, A. (2015). Comparison of the optimized thermal performance of square and circular ammonia-cooled microchannel heat sink with genetic algorithm. Energy Conversion and Management, 102, 59–65. https://doi.org/10.1016/j.enconman.2015.02.008

Tan, H., Wu, L., Wang, M., Yang, Z., & Du, P. (2019). Heat transfer improvement in microchannel heat sink by topology design and Optimization for high heat flux chip cooling. International Journal of Heat and Mass Transfer, 129, 681–689. https://doi.org/10.1016/j.ijheatmasstransfer.2018.09.092

Lorenzini-Gutierrez, D., & Kandlikar, S. G. (2014). Variable fin density flow channels for effective cooling and mitigation of temperature nonuniformity in three-dimensional integrated circuits. Journal of Electronic Packaging, Transactions of the ASME, 136, 1–11. https://doi.org/10.1115/1.4027091

Reddy, S. R., Abdoli, A., Dulikravich, G. S., Pacheco, C. C., Vasquez, G., Jha, R., Colaco, M. J., & Orlande, H. R. B. (2017). Multi-objective optimization of micro Pin–fin arrays for cooling of high heat flux electronics with a hot spot. Heat Transfer Engineering, 38, 1235–1246. https://doi.org/10.1080/01457632.2016.1242953

Vilarrubí, M., Riera, S., Ibañez, M., Omri, M., Laguna, G., Fréchette, L., & Barrau, J. (2018). Experimental and numerical study of micro-Pin–fin heat sinks with variable density for increased temperature uniformity. International Journal of Thermal Sciences, 132, 424–434. https://doi.org/10.1016/j.ijthermalsci.2018.06.019

Sakanova, A., & Tseng, K. J. (2018). Comparison of Pin–fin and finned shape heat sink for power electronics in future aircraft. Applied Thermal Engineering, 136, 364–374. https://doi.org/10.1016/j.applthermaleng.2018.03.020

Ismayilov, F., Akturk, A., & Peles, Y. (2021). Systematic micro heat sink optimization based on hydrofoil shape pin fins. Case Studies in Thermal Engineering., 26, 101028. https://doi.org/10.1016/j.csite.2021.101028

Bejan, A., Tsarsaronis, G., & Moran, M. (1996). Thermal Design and Optimization. Wiley.

Iyengar, M., & Bar-Cohen, A. (2003). Least-energy optimization of forced convection plate-fin heat sinks. IEEE Transactions on Components and Packaging Technologies, 26, 62–70. https://doi.org/10.1109/TCAPT.2003.811484

Yang, Y., Wang, Y., & Liao, Q. (2022). CNC corner milling parameters optimization based on variable-fidelity metamodel and improved MOPSO regarding energy consumption, international journal of precision engineering and manufacturing-green. Technology, 9, 977–995. https://doi.org/10.1007/s40684-021-00338-3

Liang, C. H., Zeng, S., Li, Z. X., Yang, D. G., & Sherif, S. A. (2016). Optimal design of plate-fin heat sink under natural convection using a particle swarm optimization algorithm. International Journal of Heat and Technology, 34, 275–280. https://doi.org/10.18280/ijht.340217

Hamadneh, N., Khan, W. A., Sathasivam, S., & Ong, H. C. (2013). Design optimization of pin fin geometry using particle swarm optimization algorithm. PLoS ONE, 8, 1–9. https://doi.org/10.1371/journal.pone.0066080

Wang, H., Luo, X., Wang, Y., & Sun, J. (2023). Identification of heat transfer coefficients in continuous casting by a GPU-based improved comprehensive learning particle swarm optimization algorithm. International Journal of Thermal Sciences, 190, 108284. https://doi.org/10.1016/j.ijthermalsci.2023.108284

Sai, J. P., & Nageswara Rao, B. (2022). Non-dominated sorting genetic algorithm II and particle Swarm optimization for design optimization of shell and tube heat exchanger. International Communications in Heat and Mass Transfer, 132, 105896. https://doi.org/10.1016/j.icheatmasstransfer.2022.105896

Azarkish, H., Farahat, S., & Sarvari, S. M. H. (2012). Comparing the performance of the particle swarm optimization and the genetic algorithm on the geometry design of longitudinal fin. Eps, 5, 836–839.

Mostaghimi, H., Park, S. S., Lee, D. Y., Nam, S., & Nam, E. (2023). Prediction of tool tip dynamics through machine learning and inverse receptance coupling. International Journal of Precision Engineering and Manufacturing. https://doi.org/10.1007/s12541-023-00831-6

Ramesh, M., Sundararaman, K. A., Sabareeswaran, M., & Srinivasan, R. (2022). Development of hybrid artificial neural network-particle swarm optimization model and comparison of genetic and particle swarm algorithms for optimization of machining fixture layout. International Journal of Precision Engineering and Manufacturing., 23, 1411–1430. https://doi.org/10.1007/s12541-022-00698-z

Barrera, J., Lvarez-Bajo, O., Flores, J. J., & Coello, C. A. C. (2016). Limiting the velocity in the particle swarm optimization algorithm. Computacion y Sistemas, 20, 635–645. https://doi.org/10.13053/CyS-20-4-2505

Khan, W. A., Culham, J. R., & Yovanovich, M. M. (2004). Optimization of Pin–fin heat sinks using entropy generation minimization. Thermomechanical Phenomena in Electronic Systems-Proceedings of the Intersociety Conference, 1, 259–267. https://doi.org/10.1109/itherm.2004.1319183

Kishore, H., Nirala, C. K., & Agrawal, A. (2023). Thermal performance index based characterization and experimentation validation for heat dissipation by unconventional arrayed Pin–fins. Thermal Science Engineering Progress, 45, 102015. https://doi.org/10.1016/j.tsep.2023.102015

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kishore, H., Pal, M., Nirala, C.K. et al. Thermal Performance Evaluation of Micro Pin–Fin Heat Exchangers: Part I—Geometrical Design Parameters Optimization. Int. J. Precis. Eng. Manuf. 25, 245–254 (2024). https://doi.org/10.1007/s12541-023-00925-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12541-023-00925-1