Abstract

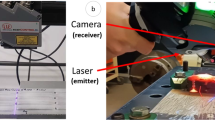

This paper presents a non-destructive inspection system for the self-piercing riveting (SPR) in carbon fiber reinforced plastic (CFRP)-metal joining products. The system employs a 6-degree of freedom robotic manipulator with a stereo vision system to measure the 3D depth and 2D surface profile of the joint using stereoscopic images. The proposed method applies a feature-selected segmentation algorithm and support vector machine to detect defects in the joints by comparing height differences between the target point profile and the target surroundings background profile. To verify the accuracy and performance of the proposed system, normal and abnormal cases were measured and classified using CFRP plate samples, and the method was then applied to the SPR joint in a CFRP b-pillar sample. The results demonstrate that the proposed system is reliable and accurate and has potential for real-world applications due to its high accuracy and reliability for quality control in SPR joint manufacturing.

Similar content being viewed by others

References

Doo, R. (1993). Automotive body construction using self-piercing riveting. Automotive Manufacturing International, 102(9), 51–56.

Moss, S., & Mahendran, M. (2002). Structural behaviour of self-piercing riveted connections in steel framed housing. International Journal of Precision Engineering and Manufacturing (IJPEM), 3(3), 29–36.

Litherland, H. (1999). Aluminium applications. In Joints in aluminium-INALCO'98: Seventh international conference (pp. 135–140). Woodhead Publishing.

Ang, H. Q. (2021). An overview of self-piercing riveting process with focus on joint failures, corrosion issues and optimisation techniques. Chinese Journal of Mechanical Engineering, 34(1), 1–25.

Haque, R. (2018). Quality of self-piercing riveting (SPR) joints from cross-sectional perspective: A review. Archives of Civil and Mechanical Engineering, 18(1), 83–93.

Westerberg, C. (2002). Finite element simulation of crash testing of self-piercing rivet joints, peel specimen. International Journal of Precision Engineering and Manufacturing (IJPEM), 3(3), 9–16.

Tang, D. X., Barthelemy, B., & Yuan, H. (2002). Self-pierced rivet (SPR) modeling in aluminum structure crash analysis. ASME International Mechanical Engineering Congress and Exposition, 36568, 207–222.

Zhang, X., He, X., Wei, W., Lu, J., & Zeng, K. (2020). Fatigue characterization and crack propagation mechanism of self-piercing riveted joints in titanium plates. International Journal of Fatigue, 134, 105465.

Zhao, L., He, X., Xing, B., Zhang, X., Cheng, Q., Gu, F., & Ball, A. (2017). Fretting behavior of self-piercing riveted joints in titanium sheet materials. Journal of Materials Processing Technology, 249, 246–254.

Haque, R., Williams, N. S., Blacket, S. E., & Durandet, Y. (2015). A simple but effective model for characterizing SPR joints in steel sheet. Journal of Materials Processing Technology, 223, 225–231.

Li, D., Chrysanthou, A., Patel, I., & Williams, G. (2017). Self-piercing riveting-a review. The International Journal of Advanced Manufacturing Technology, 92, 1777–1824.

Han, L., Hewitt, R., Shergold, M., Chrysanthou, A., & Stepinski, T. (2007). An evaluation of NDT for self-pierce riveting. SAE World Congress.

Stepinski, T. (2006). Assessing quality of self-piercing rivets using ultrasound. In European conference on non-destructive testing.

Tian, H., Xing, B., Zhang, H., Wang, K., Zeng, K., & He, X. (2022). A study on non-destructive testing of geometrical parameters of self-piercing riveting joints using an acoustic microscope with a scanning focusing converter. Nondestructive Testing and Evaluation 1–14.

Gay, A., Roche, J. M., Lapeyronnie, P., Valiorgue, F., & Bertrand, P. (2017). Non-destructive inspection of initial defects of PA6. 6-GF50/aluminum self-piercing riveted joints and damage monitoring under mechanical static loading. International Journal of Damage Mechanics, 26(8), 1127–1146.

Okafor, A. C., & Natarajan, S. (2007). Multifrequency eddy current inspection of corrosion in clad aluminum riveted lap joints and its effect on fatigue life. AIP Conference Proceedings, 894(1), 1274–1281.

Kim, J., Chun, H., & Lee, C. (2022). Non-destructive surface profiling and inspection by using a single unit magneto-eddy current sensor. Journal of Manufacturing Science and Engineering. 1–10.

Faugeras, O., & Faugeras, O. A. (1993). Three-dimensional computer vision: A geometric viewpoint. Cambridge: MIT Press.

Zhang, Z. (2000). A flexible new technique for camera calibration. IEEE Transactions on Pattern Analysis and Machine Intelligence, 22(11), 1330–1334.

Acknowledgements

This research has been supported by Ministry of Trade, Industry and Energy (KEIT, Project No.20011498, Robotic CFRP- metal mechanical joining and adhesive bonding process for future automotive applications).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Lee, H., Kim, J., Guo, X. et al. Non-destructive Inspection System for Self-piercing Riveting in CFRP-Metal Joining Product Using Stereoscopic Method with Robotic Manipulator. Int. J. Precis. Eng. Manuf. 24, 1625–1631 (2023). https://doi.org/10.1007/s12541-023-00888-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12541-023-00888-3