Abstract

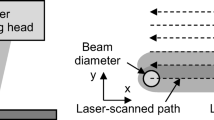

This paper proposes a novel electrochemical etching process without the need for a metal mask or photo-resist mask. The selective electrochemical etching using laser-patterned (SEEL) copper layer process consists of three steps: electrodeposition, laser patterning, and electrochemical etching. In the SEEL copper layer process, a deposited copper layer was formed on stainless steel by an electrodeposition process. A patterned copper layer on stainless steel was formed by laser beam irradiation. A patterned copper layer serves as both a sacrificial layer and a protective mask during the electrochemical etching process. The results were observed via scanning electron microscopy and surface profiler measurement. The appropriate conditions for stable SEEL copper layer process were determined. Finally, selective electrochemical etching with various micro patterns on stainless steel was been successfully performed.

Similar content being viewed by others

References

Chung, D. K., Shin, H. S., Park, M. S., Kim, B. H., & Chu, C. N. (2011). Recent researches in micro electrical machining. International Journal of Precision Engineering and Manufacturing, 12(2), 371–380.

Datta, M., & Landolt, D. (2000). Fundamental aspects and applications of electrochemical microfabrication. Electrochimica Acta, 45(1516), 2535–2558.

Chen, W., Han, F., & Wang, J. (2018). Influence of pulse waveform on machining accuracy in electrochemical machining. The International Journal of Advanced Manufacturing Technology, 96(1–4), 1367–1375.

Ryu, S. H. (2015). Eco-Friendly ECM in citric acid electrolyte with microwire and microfoil electrodes. International Journal of Precision Engineering and Manufacturing, 16(2), 233–239.

Chen, X., Qu, N., Li, H., & Guo, Z. (2015). Removal of islands from micro-dimple arrays prepared by through-mask electrochemical micromachining. Precision Engineering, 39, 204–211.

Zhang, X., Qu, N., & Chen, X. (2016). Sandwich-like electrochemical micromachining of micro-dimples. Surface & Coatings Technology, 302, 438–447.

Qu, N. S., Zhang, X. F., Chen, X. L., Li, H. S., & Zhu, D. (2015). Modified microscale pattern transfer without photolithography of substrates. Journal of Materials Processing Technology, 218, 71–79.

Qu, N. S., Zhang, X. F., Chen, X. L., Li, H. S., & Zhu, D. (2015). Modified microscale pattern transfer without photolithography of substrates. Journal of Materials Processing Technology, 218, 71–79.

Ferri, Y., Piotrowski, O., Chauvy, P. F., Madore, C., & Landolt, D. (2001). Two-level electrochemical micromachining of titanium for device fabrication. Journal of Micromechanics and Microengineering, 11(5), 522–527.

Chauvy, P. F., Hoffmann, P., & Landolt, D. (2003). Applications of laser lithography on oxide film to titanium micromachining. Applied Surface Science, 208–209, 165–170.

Chauvy, P. F., Hoffmann, P., & Landolt, D. (2003). Electrochemical micromachining of titanium using laser oxide film lithography: excimer laser irradiation of anodic oxide. Applied Surface Science, 211(1–4), 113–127.

Shin, H. S., Chung, D. K., Park, M. S., Kim, B. H., & Chu, C. N. (2010). Electrochemical etching of stainless steel through laser masking. Journal of Micromechanics and Microengineering, 20(5), 055030.

Shin, H. S., Chung, D. K., Park, M. S., & Chu, C. N. (2011). Analysis of machining characteristics in electrochemical etching using laser masking. Applied Surface Science, 258(5), 1689–1698.

Acknowledgement

This work was supported by the National Research Foundation of Korea (NRF) grant funded by the Korea government (MSIT) (No. 2017R1C1B1005444).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Shin, HS. Selective Electrochemical Etching of Stainless Steel Using a Laser-Patterned Copper Layer. Int. J. Precis. Eng. Manuf. 20, 711–716 (2019). https://doi.org/10.1007/s12541-019-00099-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12541-019-00099-9