Abstract

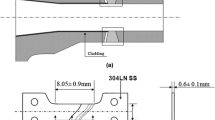

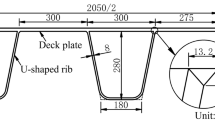

Dissimilar metal girth welded joints have been widely used due to their efficient implementation and cost-effectiveness. It is of critical significance to understand the knowledge of residual stresses by numerical technology to determine precision requirements for manufacturing practice. A multi-layer welding process of a dissimilar welded joint is simulated in this literature by coupled thermalmechanical analysis. The welding simulation model is verified by previous experimental work. The magnitudes and distributions of residual stresses in a dissimilar girth pipe joint are predicted. This study describes the influence of welding sequences and the welding start/stop positions on residual stress profiles by the simulation model. Constraint conditions is considered to analyze residual stresses in such a dissimilar welded joint. The results demonstrate that residual stresses are asymmetrical in dissimilar pipe joints due to the difference in material properties. Residual stress profiles are considerably different since the effect of welding sequence and welding start/stop positions. The variations of residual stresses on both sides of the weld centerline are more complex than those in similar welded joints. Optimized welding sequence and appropriate constraint conditions are necessary to control welding residual stress and distortion of such dissimilar welded structures.

Similar content being viewed by others

References

Withers, P. J., “Residual Stress And Its Role in Failure,” Reports on Progress in Physics, Vol. 70, No. 12, pp. 2211–2264, 2007.

Lee, C.-H. and Chang, K.-H., “Comparative Study on Girth Weld-Induced Residual Stresses between Austenitic and Duplex Stainless Steel Pipe Welds,” Applied Thermal Engineering, Vol. 63, No. 1, pp. 140–150, 2014.

Eisazadeh, H., Achuthan, A., Goldak, J. A., and Aidun, D. K., “Effect of Material Properties and Mechanical Tensioning Load on Residual Stress Formation in GTA 304-A36 Dissimilar Weld,” Journal of Materials Processing Technology, Vol. 222, pp. 344–355, 2015.

Woo, W., Em, V., Hubbard, C. R., Lee, H.-J., and Park, K. S., “Residual Stress Determination in a Dissimilar Weld Overlay Pipe by Neutron Diffraction,” Materials Science and Engineering: A, Vol. 528, No. 27, pp. 8021–8027, 2011.

Chupakhin, S., Kashaev, N., and Huber, N., “Effect of Elasto-Plastic Material Behaviour on Determination of Residual Stress Profiles Using the Hole Drilling Method,” The Journal of Strain Analysis for Engineering Design, Vol. 51, No. 8, pp. 572–581, 2016.

Wu, Q. and Li, D.-P., “Analysis and X-Ray Measurements of Cutting Residual Stresses in 7075 Aluminum Alloy in High Speed Machining,” Int. J. Precis. Eng. Manuf., Vol. 15, No. 8, pp. 1499–1506, 2014.

Zhao, L., Liang, J., Zhong, Q., Yang, C., Sun, B., and Du, J., “Numerical Simulation on the Effect of Welding Parameters on Welding Residual Stresses in T92/S30432 Dissimilar Welded Pipe,” Advances in Engineering Software, Vol. 68, pp. 70–79, 2014.

Song, T.-K., Oh, C.-Y., Kim, J.-S., Kim, Y.-J., Lee, K.-S., and Park, C.-Y., “The Safe-End Length Effect on Welding Residual Stresses in Dissimilar Metal Welds of Surge Nozzles,” Engineering Fracture Mechanics, Vol. 78, No. 9, pp. 1957–1975, 2011.

Deng, D., Kiyoshima, S., Ogawa, K., Yanagida, N., and Saito, K., “Predicting Welding Residual Stresses in a Dissimilar Metal Girth Welded Pipe Using 3D Finite Element Model with a Simplified Heat Source,” Nuclear Engineering and Design, Vol. 241, No. 1, pp. 46–54, 2011.

Bhattacharya, A. and Kumar, R., “Dissimilar Joining between Austenitic and Duplex Stainless Steel in Double-Shielded GMAW: A Comparative Study,” Materials and Manufacturing Processes, Vol. 31, No. 3, pp. 300–310, 2016.

Ramkumar, K. D., Patel, S. D., Praveen, S. S., Choudhury, D. J., Prabaharan, P., et al., “Influence of Filler Metals and Welding Techniques on the Structure-Property Relationships of Inconel 718 and AISI 316A Dissimilar Weldments,” Materials & Design (1980-2015), Vol. 62, pp. 175–188, 2014.

Zhang, B.-G., Zhao, J., Li, X.-P., and Chen, G.-Q., “Effects of Filler Wire on Residual Stress in Electron Beam Welded QCr0.8 Copper Alloy to 304 Stainless Steel Joints,” Applied Thermal Engineering, Vol. 80, No. pp. 261–268, 2015.

Feli, S., Aaleagha, M. A., Foroutan, M., and Farahani, E. B., “Finite Element Simulation of Welding Sequences Effect on Residual Stresses in Multipass Butt-Welded Stainless Steel Pipes,” Journal of Pressure Vessel Technology, Vol. 134, No. 1, Paper No. 011209, 2012.

Lee, C. H. and Chang, K. H., “Effect of the Welding Sequence in the Circumferential Direction on Residual Stress Distribution in a Thin-Walled Pipe Weld,” Proceedings of the Institution of Mechanical Engineers, Part B: Journal of Engineering Manufacture, Vol. 223, No. 6, pp. 723–735, 2009.

Joo, S.-M., Bang, H.-S., Bang, H.-S., and Park, K.-S., “Numerical Investigation on Welding Residual Stress and Out-of-Plane Displacement during the Heat Sink Welding Process of Thin Stainless Steel Sheets,” Int. J. Precis. Eng. Manuf., Vol. 17, No. 1, pp. 65–72, 2016.

Choobi, M. S., Haghpanahi, M., and Sedighi, M., “Investigation of the Effect of Clamping on Residual Stresses and Distortions in Butt-Welded Plates,” Scientia Iranica. Transaction B, Mechanical Engineering, Vol. 17, No. 5, pp. 387–394, 2010.

Desai, R. S. and Bag, S., “Influence of Displacement Constraints in Thermomechanical Analysis of Laser Micro-Spot Welding Process,” Journal of Manufacturing Processes, Vol. 16, No. 2, pp. 264–275, 2014.

Goldak, J., Chakravarti, A., and Bibby, M., “A New Finite Element Model for Welding Heat Sources,” Metallurgical and Materials Transactions B, Vol. 15, No. 2, pp. 299–305, 1984.

Brickstad, B. and Josefson, B. L., “A Parametric Study of Residual Stresses in Multi-Pass Butt-Welded Stainless Steel Pipes,” International Journal of Pressure Vessels and Piping, Vol. 75, No. 1, pp. 11–25, 1998.

Taljat, B., Radhakrishnan, B., and Zacharia, T., “Numerical Analysis of GTA Welding Process with Emphasis on Post-Solidification Phase Transformation Effects on Residual Stresses,” Materials Science and Engineering: A, Vol. 246, No. 1, pp. 45–54, 1998.

Goldak, J. A. and Akhlaghi, M., “Computational Welding Mechanics,” Springer Science & Business Media, 2006.

Deng, D. and Murakawa, H., “Numerical Simulation of Temperature Field and Residual Stress in Multi-Pass Welds in Stainless Steel Pipe and Comparison with Experimental Measurements,” Computational Materials Science, Vol. 37, No. 3, pp. 269–277, 2006.

Karlsson, R. I. and Josefson, B. L., “Three-Dimensional Finite Element Analysis of Temperatures and Stresses in a Single-Pass Butt-Welded Pipe,” Journal of Pressure Vessel Technology, Vol. 112, No. 1, pp. 76–84, 1990.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Xia, J., Jin, H. Numerical analysis for controlling residual stresses in welding design of dissimilar materials girth joints. Int. J. Precis. Eng. Manuf. 19, 57–66 (2018). https://doi.org/10.1007/s12541-018-0007-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12541-018-0007-1