Abstract

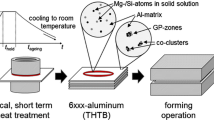

Using the cold stamping process, aluminum tailor rolled blanks (TRB) have been recently used to manufacture automotive parts to reduce the body weight of cars. However, when used to achieve uniform mechanical properties, the conventional method of aluminum TRB leads to low formability and excessive springback, and it also requires additional heat treatment because of thickness difference and work hardening during the rolling process. This study proposed an integrated hot forming and heat treatment process to improve the formability and dimensional accuracy of Al6061 TRB. In this process, the heated sheet was immediately formed after the solution heat treatment, and was then rapidly quenched within cold dies. The practicality of this process for sheet forming of Al6061 TRB was evaluated by performing the Erichsen and V-bending tests. Furthermore, hardness was measured to confirm the uniform mechanical properties of the Al6061 TRB achieved after artificial and natural aging. The integrated hot forming and heat treatment process was also compared with the conventional forming method in terms of formability, dimensional accuracy, and mechanical properties, which demonstrated the feasibility of this process for Al6061 TRB.

Similar content being viewed by others

References

Yuan, S., He, Z., and Liu, G., “New Developments of Hydroforming in China,” Materials Transactions, Vol. 53, No. 5, pp. 787–795, 2012.

Dursun, T., and Soutis, C., “Recent Developments in Advanced Aircraft Aluminium Alloys,” Materials & Design, Vol. 56, pp. 862–871, 2014.

Miles, M., Hong, S.-T., Woodward, C., and Jeong, Y.-H., “Spot Welding of Aluminum and Cast Iron by Friction Bit Joining,” Int. J. Precis. Eng. Manuf., Vol. 14, No. 6, pp. 1003–1006, 2013.

Yu, Z., Lin, Z., and Zhao, Y., “Evaluation of Fracture Limit in Automotive Aluminium Alloy Sheet Forming,” Materials & Design, Vol. 28, No. 1, pp. 203–207, 2007.

Lin, J., Dean, T. A., and Garrett, R. P., “A Process in Forming High Strength and Complex-Shaped Al-Alloy Sheet Components,” UK Patent, No. WO2008059242, 2008.

El Fakir, O., Wang, L., Balint, D., Dear, J. P., Lin, J., and Dean, T. A., “Numerical Study of the Solution Heat Treatment, Forming, and In-Die Quenching (HFQ) Process on AA5754,” International Journal of Machine Tools and Manufacture, Vol. 87, pp. 39–48, 2014.

Wang, L., Strangwood, M., Balint, D., Lin, J., and Dean, T. A., “Formability and Failure Mechanisms of AA2024 Under Hot Forming Conditions,” Materials Science and Engineering: A, Vol. 528, No. 6, pp. 2648–2656, 2011.

Garrett, R. P., Lin, J., and Dean, T. A., “Solution Heat Treatment and Cold Die Quenching in Forming AA6xxx Sheet Components: Feasibility Study,” Advanced Materials Research, Vols. 6-8, pp. 673–680, 2005.

Raugei, M., El Fakir, O., Wang, L., Lin, J., and Morrey, D., “Life Cycle Assessment of the Potential Environmental Benefits of a Novel Hot Forming Process in Automotive Manufacturing,” Journal of Cleaner Production, Vol. 83, pp. 80–86, 2014.

Fan, X., He, Z., Yuan, S., and Zheng, K., “Experimental Investigation on Hot Forming–Quenching Integrated Process of 6A02 Aluminum Alloy Sheet,” Materials Science and Engineering: A, Vol. 573, pp. 154–160, 2013.

Ko, D. H., “A Methodology to Predict the Hardness using Quenching Factor Analysis in Heat Treating and Forming of Quenchable Metals,” Ph.D. Thesis, School of Mechanical Engineering, Pusan National University, 2015.

Ko, D. H., Kim, J. H., Lee, C. J., Ko, D. C., and Kim, B. M., “Evaluation of Formability and Mechanical Characteristic for Hot Forming Quenching in Sheet Forming of Al6061 Alloy,” Transactions of the Korean Society of Mechanical Engineers A, Vol. 37, No. 4, pp. 483–490, 2013.

Fan, X., He, Z., Zheng, K., and Yuan, S., “Strengthening Behavior of Al–Cu–Mg Alloy Sheet in Hot Forming–Quenching Integrated Process with Cold–Hot Dies,” Materials & Design, Vol. 83, pp. 557–565, 2015.

Sheppard, T., “Extrusion of Aluminum Alloys,” Springer, 1999.

Li, X.-Q., Guo, G.-Q., Gao, H.-Z., Song, N., and Li, D.-S., “The Flow Behavior and Forming Limit Modeling of an Al-Cu-Mg Aluminum Alloy Sheet Considering the Effects of Pre-Strain and Solution Heat Treatment,” Int. J. Precis. Eng. Manuf., Vol. 16, No. 5, pp. 971–979, 2015.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kim, JH., Lee, CJ., Lee, SB. et al. Integrated hot forming and heat treatment process on Al6061 tailor rolled blank. Int. J. Precis. Eng. Manuf. 18, 127–132 (2017). https://doi.org/10.1007/s12541-017-0016-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12541-017-0016-5