Abstract

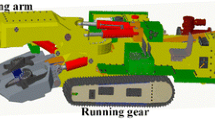

Design technologies of a cutting head attachment for mechanical excavation works are studied for improving grinding efficiency. Similar to a hydraulic breaker, a cutting head attachment is attached to the front of an excavator. However, unlike the hydraulic breaker, which breaks rocks via repeated mechanical knockings, a cutting head attachment grinds rocks via the rotational motion of a conical drum. Hence, generally the grinding efficiency and working speed of a cutting head attachment is higher than those of a hydraulic breaker. Further, the working noise is significantly low because of the same reasons. In the cutting head attachment, the grinding tools, named as pick cutters, are arranged, and they perform the role of breaking rocks by interacting with them. Hence, it is very important to arrange these tools for improving the grinding efficiency. In this study, arrangement design methodologies of several pick cutters are developed by multi-body dynamics analysis. Further, the grinding efficiency of the designed pick cutter arrangement is studied for sumping and shearing cutting works through excavator’s boom motions.

Similar content being viewed by others

Abbreviations

- φ :

-

attack angle of a pick

- θ :

-

skew angle of a pick

- ψ :

-

tilt angle of a pick

- VSpa:

-

cutting space

- VSpa_B:

-

cutting space on the base section

- VDr:

-

drum radius

- VDrnR:

-

curvature radius of a pick on the nose section

- VtoolW:

-

width of the tool

- VDl:

-

drum length

References

Chu, W.-S., Chun, D.-M., and Ahn, S.-H., “Research Advancement of Green Technologies,” Int. J. Precis. Eng. Manuf., Vol. 15, No. 6, pp. 973–977, 2014.

KURC, “Meaning of Urban Regeneration,” http://wwwkourcorkr/ tb/jsp/intro/intro01jsp?lCnt=m1&mCnt=m1 (Accessed 16 FEB 2016)

Sandvik Construction, “Tunneling Equipment,” http://construction. sandvikcom/products/tunneling-equipment/ (Accessed 16 FEB 2016)

Kahraman, S., “Correlation of TBM and Drilling Machine Performances with Rock Brittleness,” Engineering Geology, Vol. 65, No. 4, pp. 269–283, 2002.

Kwon, K.-B., Song, C.-H., Park, J.-Y., Oh, J.-Y., Lee, J.-W., and Cho, J.-W., “Evaluation of Drilling Efficiency by Percussion Testing of a Drill Bit with New Button Arrangement,” Int. J. Precis. Eng. Manuf., Vol. 15, No. 6, pp. 1063–1068, 2014.

Asbury, B., Dezeeuw, M., Cigla, M., Ozdemir, L., and Oak Creek, C., “Results of Practical Design Modifications for Respirable Dust Reduction on Continuous Miners in Underground Coal Mining,” Proc. of the Annual Meeting of the Society for Mining, Metallurgy and Exploration (SME), 2003.

Bilgin, N., Tumac, D., Feridunoglu, C., Karakas, A., and Akgul, M., “The Performance of a Roadheader in High Strength Rock Formations in KKSU Tunnel,” Proc. of the 31st ITA-AITES World Tunnel Congress, pp. 815–820, 2005.

Bilgin, N., Kuzu, C., Eskikaya, S., and Zdemir, L., “Cutting Performance of Jack Hammers and Roadheaders in Istanbul Metro Drivages,” Proc. of World Tunnel Congress, pp. 455–460, 1997.

Goktan, R. and Gunes, N., “A Semi-Empirical Approach to Cutting Force Prediction for Point-Attack Picks,” The Journal of the South African Institute of Mining and Metallurgy, Vol. 105, No. 4, pp. 257–264, 2005.

Choi, S. W., Chang, S. H., Park, Y. T., and Lee, G. P., “Performance Estimation of Conical Picks with Slim Design by the Linear Cutting Test (I): Depending on Attack Angle Variation,” Journal of Korean Tunnelling and Underground Space Association, Vol. 16, No. 6, pp. 573–584, 2014.

Choi, S. W., Chang, S. H., Park, Y. T., and Lee, G. P., “Performance Estimation of Conical Picks With Slim Design by the Linear Cutting Test (II): Depending on Skew Angle Variation,” Journal of Korean Tunnelling and Underground Space Association, Vol. 16, No. 6, pp. 585–597, 2014.

Gao, K., Du, C., Jiang, H., and Liu, S., “A Theoretical Model for Predicting the Peak Cutting Force of Conical Picks,” Fracture and Structural Integrity: Annals 2014, pp. 43–52, 2014.

Gao, K., Du, C., Jiang, H., and Liu, S., “An Empirical Mathematic Model of Drums Cutting Torque,” Journal of Theoretical and Applied Information Technology, Vol. 46, No. 2, pp. 785–789, 2012.

Tiryaki, B., Ayhan, M., and Hekimoglu, O. Z., “A New Computer Program For Cutting Head Design of Roadheaders and Drum Shearers,” Proc. of 17th International Mining Congress and Exhibition of Turkey, pp. 655–662, 2001.

Cigla, M. and Ozdemir, L., “Computer Modeling for Improved Production of Mechanical Excavators,” Proc. of SME Annual Meeting, 2000.

Nikravesh, P. E., “Computer-Aided Analysis of Mechanical Systems,” Dialnet, pp. 347–351, 2016.

FunctionBay, Inc., “User’s Guide for RecurDyn,” 2010.

Hill, W. J. and Hunter, W. G., “A Review of Response Surface Methodology: A Literature Survey,” Technometrics, Vol. 8, No. 4, pp. 571–590, 1966.

Sacks, J., Schiller, S. B., and Welch, W. J., “Designs for Computer Experiments,” Technometrics, Vol. 31, No. 1, pp. 41–47, 1989.

Eom, B.-G. and Lee, H. S., “Assessment of Running Safety of Railway Vehicles using Multibody Dynamics,” Int. J. Precis. Eng. Manuf., Vol. 11, No. 2, pp. 315–320, 2010.

Oh, K. W., Kim, D., and Hong, D., “Performance Evaluation of Excavator Control Device with EMG-based Fatigue Analysis,” Int. J. Precis. Eng. Manuf., Vol. 15, No. 2, pp. 193–199, 2014.

Chen, H. and Lee, J., “Path Planning of 5-DOF Manipulator based on Maximum Mobility,” Int. J. Precis. Eng. Manuf., Vol. 15, No. 1, pp. 45–52, 2014.

Author information

Authors and Affiliations

Corresponding author

Additional information

This paper was presented at ISGMA 2015

Rights and permissions

About this article

Cite this article

Jang, JS., Yoo, WS., Kang, H. et al. Cutting head attachment design for improving the performance by using multibody dynamic analysis. Int. J. Precis. Eng. Manuf. 17, 371–377 (2016). https://doi.org/10.1007/s12541-016-0046-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12541-016-0046-4