Abstract

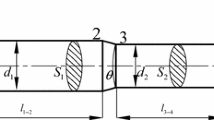

The pipeline system that is composed of fiber reinforced rubber hoses is subject to various severe dynamic excitations once an air conditioning system is mounted on vehicle, and the prolonged exposure of air conditioner to the severe vibration environments may cause micro cracks and leakage of rubber hoses. Therefore, rubber hoses are desired to have high damping performance to suppress the excessive structural vibration. Meanwhile, the fixing bracket is usually manufactured with aluminum to reduce the total weight, but it is also desired to be replaced with other material for the sake of production cost down. In this context, the natural frequencies, frequency responses and the vibration acceleration levels (VALs) of the pipeline system are analyzed by the finite element analysis and the vibration experiment was performed. As well, the vibration damping characteristics of the five-layered reinforced rubber hoses of automotive air conditioner are parametrically investigated with respect to the rubber hose hardness and the material type of fixing bracket. It is found that the soft rubber hoses provide the best damping performance, which is also verified through the actual vibration experiment. In addition, the possibility of changing the bracket material to reduce the production cost is also confirmed.

Similar content being viewed by others

References

Cho, J. R. and Moon, S. J., “A Numerical Analysis of the Interaction between the Piston Oil Film and the Component Deformation in a Reciprocating Compressor,” Tribology International, Vol. 38, No. 5, pp. 459–468, 2005.

Han, H. S., Jeong, W. B., and Kim, M. S., “Frequency Characteristics of the Noise of R600A Refrigerant Flowing in a Pipe with Intermittent Flow Pattern,” International Journal of Refrigeration, Vol. 34, No. 6, pp. 1497–1506, 2011.

Huang, Y. M., “Analysis of the Roto-Cooler Air-Conditioning System,” International Journal of Refrigeration, Vol. 18, No. 6, pp. 367–372, 1995.

Duffner, D. H., “Air Conditioner Failure Investigation-Intergranular Cracking in a Pure Copper Condenser Tube,” Journal of Failure Analysis and Prevention, Vol. 5, No. 1, pp. 79–85, 2005.

Inagaki, T. and Okamoto, Y., “Diagnosis of the Leakage Point on a Structure Surface using Infrared Thermography in Near Ambient Conditions,” NDT & E International, Vol. 30, No. 3, pp. 135–142, 1997.

Rao, M. D., “Recent Applications of Viscoelastic Damping for Noise Control in Automobiles and Commercial Airplanes,” Journal of Sound and Vibration, Vol. 262, No. 3, pp. 457–474, 2003.

Jeong, S.-H., Choi, D.-H., and Jeong, M., “Feasibility Classification of New Design Points using Support Vector Machine Trained by Reduced Dataset,” Int. J. Precis. Eng. Manuf., Vol. 13, No. 5, pp. 739–746, 2012.

Li, S.Y., Guo, J., Zhang, X. W., and Tang, W. Y., “Optimization for Pipeline System of Air-Conditioner based on Finite Element Simulation,” Applied Mechanics and Materials, pp. 2151–2155, 2012.

Park, C.-H., Shim, H.-J., Choi, D.-H., Kim, J.-K., and Lee, S.-M., “Shape Optimization of Rubber Isolators in Automotive Cooling Modules for the Maximization of Vibration Isolation and Fatigue Life,” International Journal of Automotive Technology, Vol. 13, No. 1, pp. 61–75, 2012.

Wijaya, C., Yoon, M. C., and Kim, B. T., “Numerical Investigation on the Dynamic Characteristics of an Automotive A/C Hose,” International Journal of Automotive Technology, Vol. 13, No. 3, pp. 433–440, 2012.

Entwistle, K., “The Behaviour of Braided Hydraulic Hose Reinforced with Steel Wires,” International Journal of Mechanical Sciences, Vol. 23, No. 4, pp. 229–241, 1981.

Cho, J. R., Song, J. I., and Choi, J. H., “Prediction of Effective Mechanical Properties of Reinforced Braid by 3-D Finite Element Analysis,” Key Engineering Materials, pp. 799–804, 2006.

Cho, J. R., Song, J. I., Noh, K. T., and Jeon, D. H., “Nonlinear Finite Element Analysis of Swaging Process for Automobile Power Steering Hose,” Journal of Materials Processing Technology, Vol. 170, No. 1, pp. 50–57, 2005.

Midas IT, “User’s Manual of Midas NFX,” http://www.nfx.co.kr/ (Accessed 18 JAN 2016).

Cho, J. R., Song, J. M., and Lee, J. K., “Finite Element Techniques for the Free-Vibration and Seismic Analysis of Liquid-Storage Tanks,” Finite Elements in Analysis and Design, Vol. 37, No. 6, pp. 467–483, 2001.

Kim, Y. H., “Sound Propagation: An Impedance based Approach,” Wiley, pp. 95–97, 2010.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Han, SR., Cho, JR. Investigation of vibration damping characteristics of automotive air conditioning pipeline systems. Int. J. Precis. Eng. Manuf. 17, 209–215 (2016). https://doi.org/10.1007/s12541-016-0027-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12541-016-0027-7