Abstract

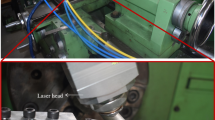

Laser-assisted turning (LAT) is an effective machining method for difficult-to-cut materials, such as nickel and ceramics. Many researchers have studied the machining characteristics and the effectiveness of LAT. However, LAT is in the early stage of application, and has only been used in a limited fashion for round workpieces. Therefore, in this paper, laser-assisted turn-mill (LATM) processing is proposed to complement LAT. LATM is able to machine various section shapes than LAT by using turning and milling processes at the same time. Additionally, the influence of parameters such as laser power, cutting speed, feed rate, and depth of cut is studied to decrease the cutting force and surface roughness. Also, the optimum machining conditions of LATM of AISI 1045 steel are determined through design of experiment

Similar content being viewed by others

References

Ding, H. and Shin, Y. C., “Laser-Assisted Machining of Hardened Steel Parts with Surface Integrity Analysis,” International Journal of Machine Tools and Manufacture, Vol. 50, No. 1, pp. 106–114, 2010.

Furumoto, T., Ueda, T., Osaka, T., Yassin, A., Hosokawa, A., and Tanaka, R., “Study on Laser Assisted Milling of Ferrous based Consolidated Material,” Journal of Mechanical Science and Technology, Vol. 24, No. 1, pp. 127–130, 2010.

Kim, J. D., Lee, S. J., and Suh, J., “Characteristics of Laser Assisted Machining for Silicon Nitride Ceramic according to Machining Parameters,” Journal of Mechanical Science and Technology, Vol. 25, No. 4, pp. 995–1001, 2011.

Ismail, M., Okamoto, Y., Okada, A., Uno, Y., and Ueoka, K., “Direct Micro-Joining of Flexible Printed Circuit and Metal Electrode by Pulsed Nd:YAG Laser,” Int. J. Precis. Eng. Manuf., Vol. 13, No. 3, pp. 321–329, 2012.

Kim, K. S., Kim, J. H., Choi, J. Y., and Lee, C. M., “A Review on Research and Development of Laser Assisted Turning,” Int. J. Precis. Eng. Manuf., Vol. 12, No. 4, pp. 753–759, 2011.

Slocombe, A. and Li, L., “Laser Ablation Machining of Metal/ Polymer Composite Materials,” Applied Surface Science, Vol. 154- 155, pp. 617-621, 2000.

Masood, S. H., Armitage, K., and Brandt, M., “An Experimental Study of Laser-Assisted Machining of Hard-to-Wear White Cast Iron,” International Journal of Machine Tools and Manufacture, Vol. 13, No. 6, pp. 450–456, 2011.

Sun, S., Brandt, M., and Dargusch, M. S., “Thermally Enhanced Machining of Hard-to-Machine Materials: A Review,” International Journal of Machine Tools and Manufacture, Vol. 50, pp. 663–680, 2010.

Jeon, Y. H. and Lee, C. M., “Current Research Trend on Laser Assisted Machining,” Int. J. Precis. Eng. Manuf., Vol. 13, No. 2, pp. 311–317, 2012.

Kim, T. W. and Lee, C. M., “Determination of the Machining Parameters of Nickel-based Alloys by High-Power Diode Laser,” Int. J. Precis. Eng. Manuf., Vol. 16, No. 2, pp. 309–314, 2015.

Sim, M.-S. and Lee, C.-M., “A Study on the Laser Preheating Effect of Inconel 718 Specimen with Rotated Angle with Respect to 2- Axis,” Int. J. Precis. Eng. Manuf., Vol. 15, No. 1, pp. 189–192, 2014.

Kim, T. W. and Lee, C. M., “Microstructural Variations Machining Characteristics of Silicon Nitride Ceramics from Increasing the Temperature in Laser Assisted Machining,” Int. J. Precis. Eng. Manuf., Vol. 15, No. 7, pp. 1269–1274, 2014.

Chang, C. W. and Kuo, C. P., “An Investigation of Laser-Assisted Machining of Al2O3 Ceramics Planning,” International Journal of Machine Tools and Manufacture, Vol. 47, pp. 452–461, 2007.

Chang, C. W. and Kuo, C. P., “Evaluation of Surface Roughness in Laser-Assisted Machining of Aluminum Oxide Ceramics with Taguchi Method,” International Journal of Machine Tools and Manufacture, Vol. 47, No. 1, pp. 141–147, 2007.

Tian, Y. and Shin, Y. C., “Thermal Modeling for Laser-Assisted Machining of Silicon Nitride Ceramics with Complex Features,” Journal of Manufacturing Science and Engineering, Vol. 128, No. 2, pp. 425–434, 2006.

Tian, Y. and Shin, Y. C., “Laser-Assisted Machining of Damage-free Silicon Nitride Parts with Complex Geometric Features via Inprocess Control of Laser Power,” Journal of American Ceramic Society, Vol. 89, No. 11, pp. 3397–3405, 2006.

Kim, J. H., Kim, K. S., Choi, J. Y., and Lee, C. M., “Estimation of Deformed Laser Heat Sources and Thermal Analysis on Laser Assisted Turning of Square Member,” Journal of Central South University, Vol. 19, No. 2, pp. 402–407, 2012.

Attia, H., Tavakoli, S., Vargas, R., and Thomson, V., “Laser-Assisted High-Speed Finish Turning of Superalloy Inconel 718 under Dry Conditions,” CIRP Annals-Manufacturing Technology, Vol. 59, No. 1, pp. 83–88, 2010.

Choi, J. Y. and Lee, C. M., “NC Code Generation for Laser Assisted Turn-Mill of Various Types of Clovers and Square Section Members,” Journal of Central South University, Vol. 19, No. 11, pp. 3064–3068, 2012.

Choi, J. Y. and Lee, C. M., “Evaluation of Cutting Force and Surface Temperature for Round and Square Member in Laser Assisted Turn-Mill,” Applied Mechanics and Materials, Vols. 229-231, pp. 718–722, 2012.

Kim, K. S., Choi, J. Y., and Lee, C. M., “A Study on the Effect of Laser Preheating on Laser Assisted Turn-Mill for machining Square and Spline Members,” Int. J. Precis. Eng. Manuf., Vol. 15, No. 2, pp. 275–282, 2014.

Kim, D. H. and Lee, C. M., “A Study of Cutting Force and Preheating-Temperature Prediction for Laser-Assisted Milling of Inconel 718 and AISI 1045 Steel,” International Journal of Heat and Mass Transfer, Vol. 71, pp. 264–274, 2014.

Zhang, J. Z., Chen, J. C., and Kirby, E. D., “Surface Roughness Optimization in an End-Milling Operation using the Taguchi Design Method,” Journal of Materials Processing Technology, Vol. 184, No. 1, pp. 233–239, 2007.

Kim, J. D., Kim, N. S., and Hong, C. S., “Design Optimization of a Xenogeneic Bone Plate and Screws using the Taguchi and Finite Element Methods,” Int. J. Precis. Eng. Manuf., Vol. 12, No. 6, pp. 1119–1124, 2011.

Yoon, H. S., Wu, R., and Lee, T. M., “Geometric Optimization of Micro Drills using Taguchi Methods and Response Surface Methodology,” Int. J. Precis. Eng. Manuf., Vol. 12, No. 5, pp. 871–875, 2011.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Cha, NH., Woo, WS. & Lee, CM. A study on the optimum machining conditions for laser-assisted turn-mill. Int. J. Precis. Eng. Manuf. 16, 2327–2332 (2015). https://doi.org/10.1007/s12541-015-0299-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12541-015-0299-3