Abstract

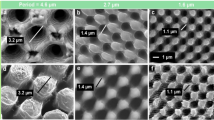

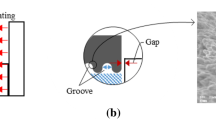

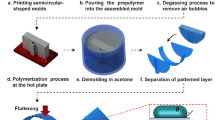

Transparent superhydrophobic surfaces have great potential for application to self-cleaning transparent windows. We suggest a fabrication method that combines laser beam machining and polymer casting. A UV nanosecond pulsed laser was used to machine arrays of holes into molds composed of 6061 aluminum alloy. Then, polydimethylsiloxane was cast into the laser-machined molds. To study the effects of the array geometry on superhydrophobicity and transparency, a series of micropillar arrays with different step sizes were fabricated. As a result, the critical step size at which the surfaces changed from hydrophobic to superhydrophobic was found to be approximately 80 μm. Cone-shaped micropillar arrays with 80 μm step size showed 175° maximum water droplet contact angle and were highly transparent throughout the 300–1000 nm spectral region. Sliding angle was observed to confirm the surfaces’ self-cleaning ability. This work opens up the possibility of mass production of superhydrophobic, transparent, self-cleaning surfaces.

Similar content being viewed by others

Abbreviations

- θ c :

-

contact angle of a water droplet on a rough surface in the partial wetting state

- ϕ 1 :

-

area fraction of water-solid surfaces

- ϕ 2 :

-

area fraction of water-air surfaces

- θ 1e :

-

equilibrium contact angle of solid-water surfaces

- θ 2e :

-

equilibrium contact angle of water-air surfaces (180°)

References

Yan, Y., Gao, N., and Barthlott, W., “Mimicking Natural Superhydrophobic Surfaces and Grasping the Wetting Process: A Review on Recent Progress in Preparing Superhydrophobic Surfaces,” Advances Colloid and Interface Science, vol. 169, no. 2, pp. 80–105, 2011.

Ganesh, V. A., Raut, H. K., Nair, A. S., and Ramakrishna, S., “A Review on Self-Cleaning Coatings,” Journal of Material Chemistry, vol. 21, no. 41, pp. 16304–16322, 2011.

Guo, Z., Liu, W., and Su, B.-L., “Superhydrophobic Surfaces: from Natural to Biomimetic to Functional,” Journal of Colloid and Interface Science, vol. 353, no. 2, pp. 335–355, 2011.

Roach, P., Shirtcliffe, N. J., and Newton, M. I., “Progess in Superhydrophobic Surface Development,” Soft Matter, vol. 4, no. 2, pp. 224–240, 2008.

Feng, L., Li, S., Li, Y., Li, H., Zhang, L., et al., “Super-Hydrophobic Surfaces: From Natural to Artificial,” Advanced Materials, vol. 14, no. 24, pp. 1857–1860, 2002.

Zhang, X., Shi, F., Niu, J., Jiang, Y., and Wang, Z., “Superhydrophobic Surfaces: From Structural Control to Functional Application,” Journal of Materials Chemistry, vol. 18, no. 6, pp. 621–633, 2008.

Barthwal, S., Kim, Y. S., and Lim, S. H., “Superhydrophobic and Superoleophobic Copper Plate Fabrication using Alkaline Solution Assisted Surface Oxidation Methods,” Int. J. Precis. Eng. Manuf., vol. 13, no. 8, pp. 1311–1315, 2012.

Lee, J. M., Lee, M. C., Lee, S. h., and Ko, J. S., “Evaluation of Surface Wettability by Means of the Measurement of the Adhesive Force between a Microstructured Hydrophobic Surface and a Water Droplet,” Int. J. Precis. Eng. Manuf., vol. 15, no. 11, pp. 2397–2404, 2014.

Lee, S. H., Lee, J. H., Park, C. W., Lee, C. Y., Kim, K., et al., “Continuous Fabrication of Bio-Inspired Water Collecting Surface Via Roll-Type Photolithography,” Int. J. Precis. Eng. Manuf.-Green Tech., vol. 1, no. 2, pp. 119–124, 2014.

Kim, Y. W., Lee, J. M., Lee, I., Lee, S. H., and Ko, J. S., “Skin Friction Reduction in Tubes with Hydrophobically Structured Surfaces,” Int. J. Precis. Eng. Manuf., vol. 14, no. 2, pp. 299–306, 2013.

Lee, S. M., Oh, D. J., Jung, I. D., Bae, K. M., Jung, P. G., et al., “Fabrication of Nickel Micromesh Sheets and Evaluation of Their Water-Repellent and Water-Proof Abilities,” Int. J. Precis. Eng. Manuf., vol. 10, no. 3, pp. 161–166, 2009.

Yao, X., Song, Y., and Jiang, L., “Applications of Bio-Inspired Special Wettable Surfaces,” Advanced Materials, vol. 23, no. 6, pp. 719–734, 2011.

Celia, E., Darmanin, T., Taffin de Givenchy, E., Amigoni, S., and Guittard, F., “Recent Advances in Designing Superhydrophobic Surfaces,” Journal of Colloid and Interface Science, Vol. 402, pp. 1–18, 2013.

Malshe, A., Rajurkar, K., Samant, A., Hansen, H. N., Bapat, S., et al., “Bio-Inspired Functional Surfaces for Advanced Applications,” CIRP Annals- Manufacturing Technology, vol. 62, no. 2, pp. 607–628, 2013.

Liu, B., He, Y., Fan, Y., and Wang, X., “Fabricating Super-Hydrophobic Lotus-Leaf-Like Surfaces through Soft-Lithographic Imprinting,” Macromolecular Rapid Communications, vol. 27, no. 21, pp. 1859–1864, 2006.

Pruna, A., Ramiro, J., and Belforte, L., “Preliminary Study on Different Technological Tools and Polymeric Materials Towards Superhydrophobic Surfaces for Automotive Applications,” Journal of Physics and Chemistry of Solids, vol. 74, no. 11, pp. 1640–1645, 2013.

Zhang, X. S., Jin, B. H., Chu, S. G., Peter, N., Zhu, F.-Y., et al., “Single-Step Fabrication of Superhydrophobic Micro/Nano Dual-Scale PDMS Film Replicated from Ultra-Low-Surface-Energy Mold,” Proc. of IEEE 26th International Conference on Micro Electro Mechanical Systems, pp. 331–334, 2013.

Kim, D. S., Lee, B. K., Yeo, J., Choi, M. J., Yang, W., et al., “Fabrication of PDMS Micro/Nano Hybrid Surface for Increasing Hydrophobicity,” Microelectronic Engineering, vol. 86, no. 4–6, pp. 1375–1378, 2009.

Tropmann, A., Tanguy, L., Koltay, P., Zengerle, R., and Riegger, L., “Completely Superhydrophobic PDMS Surfaces for Microfluidics,” Langmuir, vol. 28, no. 22, pp. 8292–8295, 2012.

Manca, M., Cortese, B., Viola, I., Aricò, A. S., Cingolani, R., et al., “Influence of Chemistry and Topology Effects on Superhydrophobic CF4-Plasma-Treated Poly (Dimethylsiloxane) (PDMS),” Langmuir, vol. 24, no. 5, pp. 1833–1843, 2008.

Lee, S. H., Kim, H. N., Kwak, R. K., and Suh, K. Y., “Effects of Mold Rising Angle and Polymer Concentration in Solvent-Assisted Molding,” Langmuir, vol. 25, no. 20, pp. 12024–12029, 2009.

Jeong, H. E., Kwak, M. K., Park, C. I., and Suh, K. Y., “Wettability of Nanoengineered Dual-Roughness Surfaces Fabricated by UVAssisted Capillary Force Lithography,” Journal of Colloid and Interface Science, vol. 339, no. 1, pp. 202–207, 2009.

Liu, X. and Luo, C., “Fabrication of Super-Hydrophobic Channels,” Journal of Micromechanics and Microengineering, vol. 20, no. 2, Paper No. 025029, 2010.

Groenendijk, M., “Fabrication of Super Hydrophobic Surfaces by FS Laser Pulses,” Laser Technik Journal, vol. 5, no. 3, pp. 44–47, 2008.

Noh, J., Lee, J. H., Na, S., Lim, H., and Jung, D. H., “Fabrication of Hierarchically Micro- and Nano-Structured Mold Surfaces using Laser Ablation for Mass Production of Superhydrophobic Surfaces,” Japanese Journal of Applied Physics, Vol. 49, No. 10R, Paper No. 106502, 2010.

Chichkov, B. N., Momma, C., Nolte, S., Alvensleben, F., and Tünnermann, A., “Femtosecond, Picosecond and Nanosecond Laser Ablation of Solids,” Applied Physics A Materials Science & Processing, vol. 63, no. 2, pp. 109–115, 1996.

Bekesi, J., Kaakkunen, J. J. J., Michaeli, W., Klaiber, F., Schoengart, M., et al., “Fast Fabrication of Super-Hydrophobic Surfaces on Polypropylene by Replication of Short-Pulse Laser Structured Molds,” Applied Physics A, vol. 99, no. 4, pp. 691–695, 2010.

Kam, D. H., Bhattacharya, S., and Mazumder, J., “Control of the Wetting Properties of an AISI 316L Stainless Steel Surface by Femtosecond Laser-Induced Surface Modification,” Journal of Micromechanics and Microengineering, vol. 22, no. 10, Paper No. 105019, 2012.

Jagdheesh, R., Pathiraj, B., Karatay, E., Römer, G. R. B. E., and Huis in’t Veld, A. J., “Laser-Induced Nanoscale Superhydrophobic Structures on Metal Surfaces,” Langmuir, vol. 27, no. 13, pp. 8464–8469, 2011.

Cardoso, M. R., Tribuzi, V., Balogh, D. T., Misoguti, L., and Mendonça, C. R., “Laser Microstructuring for Fabricating Superhydrophobic Polymeric Surfaces,” Applied Surface Science, vol. 257, no. 8, pp. 3281–3284, 2011.

Jiang, T., Koch, J., Unger, C., Fadeeva, E., Koroleva, A., et al., “Ultrashort Picosecond Laser Processing of Micro-Molds for Fabricating Plastic Parts with Superhydrophobic Surfaces,” Applied Physics A, vol. 108, no. 4, pp. 863–869, 2012.

Bruzzone, A. A. G., Costa, H. L., Lonardo, P. M., and Lucca, D. A., “Advances in Engineered Surfaces for Functional Performance,” CIRP Annals- Manufacturing Technology, vol. 57, no. 2, pp. 750–769, 2008.

Pan, Z., Shahsavan, H., Zhang, W., Yang, F. K., and Zhao, B., “Superhydro-Oleophobic Bio-Inspired Polydimethylsiloxane Micropillared Surface via FDTS Coating/Blending Approaches,” Applied Surface Science, vol. 324, pp. 612–620, 2015.

Vourdas, N., Tserepi, A., and Gogolides, E., “Nanotextured Super-Hydrophobic Transparent Poly(Methyl Methacrylate) Surfaces using High-Density Plasma Processing,” Nanotechnology, vol. 18, no. 12, Paper No. 125304, 2007.

Aytug, T., Simpson, J. T., Lupini, A. R., Trejo, R. M., Jellison, G. E., et al., “Optically Transparent, Mechanically Durable, Nanostructured Superhydrophobic Surfaces Enabled by Spinodally Phase-Separated Glass Thin Films,” Nanotechnology, vol. 24, no. 31, Paper No. 315602, 2013.

Kim, M., Kim, K., Lee, N. Y., Shin, K., and Kim, Y. S., “A Simple Fabrication Route to a Highly Transparent Super-Hydrophobic Surface with a Poly(Dimethylsiloxane) Coated Flexible Mold,” Chemical Communications, no. 22, pp. 2237–2239, 2007.

Nakajima, A., Hashimoto, K., Watanabe, T., Takai, K., Yamauchi, G., et al., “Transparent Superhydrophobic Thin Films with Self-Cleaning Properties,” Langmuir, vol. 16, no. 17, pp. 7044–7047, 2000.

Im, M., Im, H., Lee, J.-H., Yoon, J.-B., and Choi, Y.-K., “A Robust Superhydrophobic and Superoleophobic Surface with Inverse-Trapezoidal Microstructures on a Large Transparent Flexible Substrate,” Soft Matter, vol. 6, no. 7, pp. 1401–1404, 2010.

Sas, I., Gorga, R. E., Joines, J. A., and Thoney, K. A., “Literature Review on Superhydrophobic Self-Cleaning Surfaces Produced by Electrospinning,” Journal of Polymer Science Part B: Polymer Physics, vol. 50, no. 12, pp. 824–845, 2012.

Chun, D. M., Davaasuren, G., Ngo, C. V., Kim, C. S., Lee, G. Y., et al., “Fabrication of Transparent Superhydrophobic Surface on Thermoplastic Polymer using Laser Beam Machining and Compression Molding for Mass Production,” CIRP Annals-Manufacturing Technology, vol. 63, no. 1, pp. 525–528, 2014.

Stalder, A. F., Kulik, G., Sage, D., Barbieri, L., and Hoffmann, P., “A Snake-based Approach to Accurate Determination of both Contact Points and Contact Angles,” Colloids and Surfaces A: Physicochemical and Engineering Aspects, vol. 286, no. 1–3, pp. 92–103, 2006.

Cassie, A. B. D. and Baxter, S., “Wettability of Porous Surfaces,” Transactions of the Faraday Society, vol. 40, pp. 546–551, 1944.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ngo, CV., Davaasuren, G., Oh, HS. et al. Transparency and superhydrophobicity of cone-shaped micropillar array textured polydimethylsiloxane. Int. J. Precis. Eng. Manuf. 16, 1347–1353 (2015). https://doi.org/10.1007/s12541-015-0177-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12541-015-0177-z