Abstract

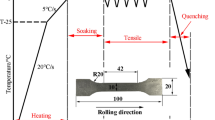

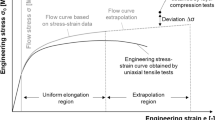

Al-Cu-Mg aluminum alloy sheet is widely used for aircraft skin. Multi-stage forming combined with Solution Heat Treatment (SHT) is necessary for some geometrically complex productions in aircraft skin components. However, the effects of pre-strain and natural ageing time on the formability of Al-Cu-Mg aluminum alloy sheet are not fully understood. In this study, the deformation responses of an Al-Cu-Mg aluminum alloy sheet, over a range of pre-strain levels (0% to 6%) and natural ageing time levels (0 h to 2 h) were investigated. A modified Hollomon constitutive model coupling with pre-strain and natural ageing time was proposed to characterize the deformation responses of the Al-Cu-Mg aluminum alloy sheet. The hemispherical dome tests were performed at natural ageing time levels ranging from 0.25 h to 1.5 h. Marciniak and Kuczynski (M-K) theory was used to obtain the forming limit prediction model which takes pre-strain and natural ageing time into account. The theoretical Forming Limit Curves (FLCs) were compared with the experimental results.

Similar content being viewed by others

References

Hu, J., Ikeda, K., and Murakami, T., “Effect of Texture Components on Plastic Anisotropy and Formability of Aluminium Alloy Sheets,” Journal of Materials Processing Technology, Vol. 73, No. 1, pp. 49–56, 1998.

Woodward, R., “Developments in Aluminium Alloys,” Materials & Design, Vol. 10, No. 5, pp. 248–254, 1989.

Tajally, M. and Emadoddin, E., “Mechanical and Anisotropic Behaviors of 7075 Aluminum Alloy Sheets,” Materials & Design, Vol. 32, No. 3, pp. 1594–1599, 2011.

Taylor, A., Weiss, M., Hilditch, T., Stanford, N., and Hodgson, P., “Formability of Cryo-Rolled Aluminium in Uniaxial and Biaxial Tension,” Materials Science and Engineering: A, Vol. 555, pp. 148–153, 2012.

Li, C., Liu, D., Yu, H., and Ji, Z., “Research on Formability of 5052 Aluminum Alloy Sheet in a Quasi-Static-Dynamic Tensile Process,” International Journal of Machine Tools and Manufacture, Vol. 49, No. 2, pp. 117–124, 2009.

Velmanirajan, K., Thaheer, A. S. A., Narayanasamy, R., and Basha, C. A., “Numerical Modelling of Aluminium Sheets Formability using Response Surface Methodology,” Materials & Design, Vol. 41, No. pp. 239–254, 2012.

Liu, J., Liu, W., and Xue, W., “Forming Limit Diagram Prediction of AA5052/Polyethylene/AA5052 Sandwich Sheets,” Materials & Design, Vol. 46, pp. 112–120, 2013.

da Rocha, A. B., Santos, A. D., Teixeira, P., and Butuc, M., “Analysis of Plastic Flow Localization under Strain Paths Changes and Its Coupling with Finite Element Simulation in Sheet Metal Forming,” Journal of Materials Processing Technology, Vol. 209, No. 11, pp. 5097–5109, 2009.

Stoughton, T. B., “A General Forming Limit Criterion for Sheet Metal Forming,” International Journal of Mechanical Sciences, Vol. 42, No. 1, pp. 1–27, 2000.

Keeler, S. P. and Backofen, W. A., “Plastic Instability and Fracture in Sheets Stretched Over Rigid Punches,” ASM Transactions Quarterly, Vol. 56, No. 1, pp. 25–48, 1963.

Goodwin, G. M., “Application of Strain Analysis to Sheet Metal Forming Problems in the Press Shop,” SAE Technical Paper No. 680093, 1968.

Aghaie-Khafri, M. and Mahmudi, R., “Predicting of Plastic Instability and Forming Limit Diagrams,” International Journal of Mechanical Sciences, Vol. 46, No. 9, pp. 1289–1306, 2004.

Narayanasamy, R., Ravindran, R., Manonmani, K., and Satheesh, J., “A Crystallographic Texture Perspective Formability Investigation of Aluminium 5052 Alloy Sheets at Various Annealing Temperatures,” Materials & Design, Vol. 30, No. 5, pp. 1804–1817, 2009.

Zhalehfar, F., Hosseinipour, S. J., Nourouzi, S., and Gorji, A. H., “A Different Approach for Considering the Effect of Non-Proportional Loading Path on the Forming Limit Diagram of AA5083,” Materials & Design, Vol. 50, pp. 165–173, 2013.

Khan, A. S. and Baig, M., “Anisotropic Responses, Constitutive Modeling and the Effects of Strain-Rate and Temperature on the Formability of an Aluminum Alloy,” International Journal of Plasticity, Vol. 27, No. 4, pp. 522–538, 2011.

Nurcheshmeh, M. and Green, D. E., “Prediction of Sheet Forming Limits with Marciniak and Kuczynski Analysis using Combined Isotropic-Nonlinear Kinematic Hardening,” International Journal of Mechanical Sciences, Vol. 53, No. 2, pp. 145–153, 2011.

Kurukuri, S., Miroux, A., Wisselink, H., and van den Boogaard, T., “Simulation of Stretch Forming with Intermediate Heat Treatments of Aircraft Skins,” International Journal of Material Forming, Vol. 4, No. 2, pp. 129–140, 2011.

Khan, I., Starink, M., and Yan, J. L., “A Model for Precipitation Kinetics and Strengthening in Al-Cu-Mg Alloys,” Materials Science and Engineering: A, Vol. 472, No. 1, pp. 66–74, 2008.

Shi, L., Yang, H., Guo, L. G., and Zhang, J., “Constitutive Modeling of Deformation in High Temperature of a Forging 6005A Aluminum Alloy,” Materials & Design, Vol. 54, pp. 576–581, 2014.

Tian, Y., Huang, L., Ma, H., and Li, J., “Establishment and Comparison of Four Constitutive Models of 5A02 Aluminium Alloy in High-Velocity Forming Process,” Materials & Design, Vol. 54, pp. 587–597, 2014.

El Mehtedi, M., Musharavati, F., and Spigarelli, S., “Modelling of the Flow Behaviour of Wrought Aluminium Alloys at Elevated Temperatures by a New Constitutive Equation,” Materials & Design, Vol. 54, pp. 869–873, 2014.

O’Donnell, M., Banabic, D., Leacock, A., Brown, D., and McMurray, R., “The Effect of Pre-Strain and Inter-Stage Annealing on the Formability of a 2024 Aluminium Alloy,” International Journal of Material Forming, Vol. 1, No. 1, pp. 253–256, 2008.

O'Donnell, M., Leacock, A., Banabic, D., Brown, D., and McMurray, R., “The Effect of Pre-Strain and Solution Heat Treatment on the Formability of a 2024 Aluminium Alloy,” International Journal of Material Forming, Vol. 1, No. 1, pp. 257–260, 2008.

O’Donnell, M., Banabic, D., Leacock, A., Brown, D., and McMurray, R., “The Effect of Pre-Strain and Inter-Stage Annealing on the Formability of a 2024 Aluminium Alloy,” International Journal of Material Forming, Vol. 1, No. 1, pp. 253–256, 2008.

Ashbridge, M. T. J., Leacock, A. G., and Gilmour, K. R., “The Effect of Solution Heat Treatment and Natural Ageing on the Yield Characteristics of a 2024-O Aluminium Alloy,” Proc. of the ASME International Mechanical Engineering Congress and Exposition, pp. 675–683, 2000.

Ozturk, F., Sisman, A., Toros, S., Kilic, S., and Picu, R. C., “Influence of Aging Treatment on Mechanical Properties of 6061 Aluminum Alloy,” Materials & Design, Vol. 31, No. 2, pp. 972–975, 2010.

Moy, C. K., Weiss, M., Xia, J., Sha, G., Ringer, S. P., and Ranzi, G., “Influence of Heat Treatment on the Microstructure, Texture and Formability of 2024 Aluminium Alloy,” Materials Science and Engineering: A, Vol. 552, pp. 48–60, 2012.

ISO 6892-1, “Metallic Materials-Tensile Testing-Part 1: Method of Test at Room Temperature,” 2009.

ISO 12004-2, “Metallic Materials-Sheet and Strip-Determination of Forming-Limit Curves-Part 2: Determination of Forming-Limit Curves in the Laboratory,” 2008.

Hosford, W. F., “On Yield Loci of Anisotropic Cubic Metals,” Proc. of the 7th North American metalworking Research Conference, pp. 191–196, 1979.

Marciniak, Z. and Kuczyñski, K., “Limit Strains in the Processes of Stretch-Forming Sheet Metal,” International Journal of Mechanical Sciences, Vol. 9, No. 9, pp. 609–620, 1967.

Kuroda, M. and Tvergaard, V., “Forming Limit Diagrams for Anisotropic Metal Sheets with Different Yield Criteria,” International Journal of Solids and Structures, Vol. 37, No. 37, pp. 5037–5059, 2000.

Graf, A. and Hosford, W. F., “Calculations of Forming Limit Diagrams,” Metallurgical Transactions A, Vol. 21, No. 1, pp. 87–94, 1990.

Li, X., Guo, G., Xiao, J., Song, N., and Li, D., “Constitutive Modeling and the Effects of Strain-Rate and Temperature on the Formability of Ti-6Al-4V Alloy Sheet,” Materials & Design, Vol. 55, pp. 325–334, 2014.

Soare, S. C., “Theoretical Considerations upon the MK Model for limit Strains Prediction: the Plane Strain Case, Strain-Rate Effects, Yield Surface Influence, and Material Heterogeneity,” European Journal of Mechanics-A/Solids, Vol. 29, No. 6, pp. 938–950, 2010.

Naka, T., Torikai, G., Hino, R., and Yoshida, F., “The Effects of Temperature and Forming Speed on the Forming Limit Diagram for Type 5083 Aluminum-Magnesium Alloy Sheet,” Journal of Materials Processing Technology, Vol. 113, No. 1, pp. 648–653, 2001.

Zhang, C., Leotoing, L., Guines, D., and Ragneau, E., “Theoretical and Numerical Study of Strain Rate Influence on AA5083 Formability,” Journal of Materials Processing Technology, Vol. 209, No. 8, pp. 3849–3858, 2009.

Bressan, J. D. and Leacock, A. G., “Influence of Pre-Strain on the Formability of 2024 Aluminium Alloy,” International Journal of Material Forming, Vol. 2, No. 1, pp. 475–478, 2009.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, XQ., Guo, GQ., Gao, HZ. et al. The flow behavior and forming limit modeling of an Al-Cu-Mg aluminum alloy sheet considering the effects of pre-strain and solution heat treatment. Int. J. Precis. Eng. Manuf. 16, 971–979 (2015). https://doi.org/10.1007/s12541-015-0126-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12541-015-0126-x