Abstract

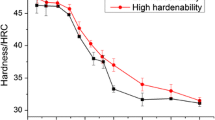

Helical gears made of low alloy carbon steel are widely used in automotives as components of power transmission because their hardened surfaces enhanced their strength and wear resistance. The hardened surface of the gear is commonly obtained by the carburizing and quenching heat treatment. However, deformation of teeth of the gear caused by the heat treatment significantly affects the dimensional accuracy of the precision part, making noise, causing vibration, and hastening malfunction of the component in the power transmission. In this study, investigation of deformation caused by the heat treatment of a helical gear made of SCM415H steel was carried out by a numerical simulation with the finite element method (FEM). In order to examine the effect of the overall characteristics of the heat treatment on the deformation, temperature history, carbon diffusion, phase transformation, and axial stress were analyzed at the same time. In addition, diffusion time and quenchant temperature were adopted specifically as process parameters to study their effects on the deformation. The simulated results revealed that the volume of the gear and the shape and lead of the tooth became somewhat smaller by heat treatment than before the process. Results showed that when the coolant temperature was increased enough, deformation of the gear was reduced.

Similar content being viewed by others

References

Kang, S. H. and Im, Y. T., “Finite Element Investigation of Multi-Phase Transformation within Carburized Carbon Steel,” Journal of Materials Processing Technology, Vol. 183, No. 2, pp. 241–248, 2007.

Song, G. S., Liu, X. H., Wang, G. D., and Xu, X. Q., “Numerical Simulation on Carburizing and Quenching of Gear Ring,” International Journal of Iron and Steel Research, Vol. 14, No. 6, pp. 47–52, 2007.

Ju, D. Y., Liu, C., and Inoue, T., “Numerical Modeling and Simulation of Carburized and Nitrided Quenching Process,” Journal of Materials Processing Technology, Vol. 143–144, pp. 880–885, 2003.

Cho, J. R., Kang, W. J., Kim, M. G., Lee, J. H., Lee, Y. S., and Bae, W. B., “Distortions Induced by Heat Treatment of Automotive Bevel Gears,” Journal of Materials Processing Technology, Vol. 153–154, pp. 476–481, 2004.

Sugianto, A., Narazaki, M., Kogawara, M., Shirayori, A., Kim, S. Y., and Kubota, S., “Numerical Simulation and Experimental Verification of Carburizing-Quenching Process of SCr420H Steel Helical Gear,” Journal of Materials Processing Technology, Vol. 209, No. 7, pp. 3597–3609, 2009.

Bae, K. Y., Yang, Y. S., and Park, B. O., “Analysis of Deformation of Automotive Helical Gear in Heat Treatment of Carburized Quenching,” J. Korean Soc. Precis. Eng., Vol. 27, No. 11, pp. 84–91, 2010.

Kim, D. W. and Lim, B. S., “Plasma and Vacuum Carburizing Processes and Mechanical Properties of SCM 415 Steel,” KSME International Journal, Vol. 13, No. 8, pp. 634–641, 1999.

Byun, J. H., Ro, S. H., Lee, J. H., Lee, C. H., and Yang, S. H., “Mechanical Properties of the Co2 Free Vacuum Carburized in SCM415H,” Transactions of the Korean Society of Mechanical Engineers A, Vol. 36, No. 9, pp. 971–978, 2012.

Fluhrer, J., “DEFORMTM-3D Version 5.0 User's Manual,” Scientific Forming Technologies Corporation, 2005.

Sente Softward Corp., “JMaPro Version 4.1,” 2007.

Linnert, G. E., “Welding Metallurgy,” American Welding Society, pp. 334–337, 1967.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kim, NK., Bae, KY. Analysis of deformation in the carburizing-quenching heat treatment of helical gears made of SCM415H steel. Int. J. Precis. Eng. Manuf. 16, 73–79 (2015). https://doi.org/10.1007/s12541-015-0009-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12541-015-0009-1