Abstract

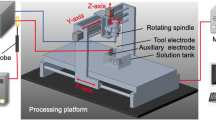

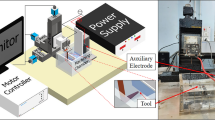

Recently, the utilization of electrochemical discharge machining (ECDM) has proved to have potential for enhancing the machining efficiency and accuracy of micro-drilling and milling for glass. However, there is a lack of information about the machining conditions for milling in quartz materials, which have different characteristics than glass. In ECDM, gas film and sparks are generated on a tool when voltage is applied between the tool and a counter electrode. Workpiece materials are removed mainly by the heat of the sparks. The spark generation is affected by both the voltage and electrolyte conditions. This study investigated the ECDM characteristics according to machining parameters, such as electrolyte level, electrolyte concentration, pulse voltage, offset pulse voltage, pulse on-time, pulse off-time, and tool feedrate. Surface roughness and sharpness of the rims and edges were observed under different machining conditions. Based on the investigation of the machining conditions, micro structures, including micro grooves and columns, were machined on quartz material.

Similar content being viewed by others

References

Zhang, C., Rentsch, R., and Brinksmeier, E., “Advances in Micro Ultrasonic Assisted Lapping of Microstructures in Hard-Brittle Materials: A Brief Review and Outlook”, International Journal of Machine Tools and Manufacture, Vol. 45, No. 7, pp. 881–890, 2005.

Cao, X. D., Kim, B. H., and Chu, C. N., “Micro-Structuring of Glass with Features Less than 100 µm by Electrochemical Discharge Machining”, Precision Engineering, Vol. 33, No. 4, pp. 459–465, 2009.

Wüthrich, R. and Fascio, V., “Machining of Non-Conducting Materials using Electrochemical Discharge Phenomenon-an Overview”, International Journal of Machine Tools and Manufacture, Vol. 45, No. 9, pp. 1095–1108, 2005.

Didar, T. F., Dolatabadi, A., and Wüthrich, R., “Characterization and Modeling of 2D-Glass Micro-Machining by Spark-Assisted Chemical Engraving (SACE) with Constant Velocity”, Journal of Micromechanics and Microengineering, Vol. 18, No. 6, Paper No. 065016, 2008.

Abou Ziki, J. D., Didar, T. F., and Wüthrich, R., “Micro-Texturing Channel Surfaces on Glass with Spark Assisted Chemical Engraving”, International Journal of Machine Tools and Manufacture, Vol. 57, pp. 66–72, 2012.

Han, M. S., Min, B. K., and Lee, S. J., “Modeling Gas Film Formation in Electrochemical Discharge Machining Processes using a Side-Insulated Electrode”, Journal of Micromechanics and Microengineering, Vol. 18, No. 4, Paper No. 045019, 2008.

Zheng, Z. P., Su, H. C., Huang, F. Y., and Yan, B. H., “The Tool Geometrical Shape and Pulse-off Time of Pulse Voltage Effects In a Pyrex Glass Electrochemical Discharge Microdrilling Process”, Journal of Micromechanics and Microengineering, Vol. 17, No. 2, pp. 265–272, 2007.

Abou Ziki, J. D. and Wüthrich, R., “Tool Wear and Tool Thermal Expansion during Micro-Machining by Spark Assisted Chemical Engraving”, The International Journal of Advanced Manufacturing Technology, Vol. 61, No. 5–8, pp. 481–486, 2012.

Yang, C. K., Wu, K. L., Hung, J. C., Lee, S. M., Lin, J. C., and Yan, B. H., “Enhancement of ECDM Efficiency and Accuracy by Spherical Tool Electrode”, International Journal of Machine Tools and Manufacture, Vol. 51, No. 6, pp. 528–535, 2011.

Jain, V. K. and Adhikary, S., “On the Mechanism of Material Removal in Electrochemical Spark Machining of Quartz under Different Polarity Conditions”, Journal of Materials Processing Technology, Vol. 200, No. 1, pp. 460–470, 2008.

Zheng, Z. P., Lin, J. K., Huang, F. Y., and Yan, B. H., “Improving the Machining Efficiency in Electrochemical Discharge Machining (ECDM) Microhole Drilling by Offset Pulse Voltage”, Journal of Micromechanics and Microengineering, Vol. 18, No. 2, 025014, 2008.

Basak, I. and Ghosh, A., “Mechanism of Spark Generation during Electrochemical Discharge Machining: A Theoretical Model and Experimental Verification”, Journal of Materials Processing Technology, Vol. 62, No. 1, pp. 46–53, 1996.

Wüthrich, R. and Bleuler, H., “A Model for Electrode Effects using Percolation Theory”, Electrochimica Acta, Vol. 49, No. 9, pp. 1547–1554, 2004.

Kim, D. J., Ahn, Y., Lee, S. H., and Kim, Y. K., “Voltage Pulse Frequency and Duty Ratio Effects in an Electrochemical Discharge Microdrilling Process of Pyrex Glass”, International Journal of Machine Tools and Manufacture, Vol. 46, No. 10, pp. 1064–1067, 2006.

Jain, V. K., Dixit, P. M., and Pandey, P. M., “On the Analysis of the Electrochemical Spark Machining Process”, International Journal of Machine Tools and Manufacture, Vol. 39, No. 1, pp. 165–186, 1999.

Jain, V. K. and Chak, S. K., “Electrochemical Spark Trepanning of Alumina and Quartz”, Machining Science and Technology, Vol. 4, No. 2, pp. 277–290, 2000.

Zheng, Z. P., Cheng, W. H., Huang, F. Y., and Yan, B. H., “3D Microstructuring of Pyrex Glass using the Electrochemical Discharge Machining Process”, Journal of Micromechanics and Microengineering, Vol. 17, No. 5, pp. 960–966, 2007.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Nguyen, KH., Lee, P.A. & Kim, B.H. Experimental investigation of ECDM for fabricating micro structures of quartz. Int. J. Precis. Eng. Manuf. 16, 5–12 (2015). https://doi.org/10.1007/s12541-015-0001-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12541-015-0001-9