Abstract

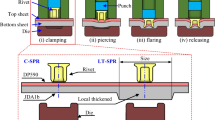

For the successful multi-material design of an automotive body, joining methods for dissimilar materials such as high-strength steel, aluminum alloy, and carbon fiber reinforced plastic (CFRP) are required for assembling automotive components comprising various materials. There are many methods for joining dissimilar materials, such as the use of self-piercing rivet, mechanical clinching, and friction stir welding. However, it is impossible to join a CFRP sheet and a metal sheet using conventional joining methods because of the former’s low ductility. This study proposes a hole-clinching process for joining CFRP with an AA6061 alloy sheet. In the holeclinching process, the AA6061 alloy sheet is indented into a hole in the CFRP and interlocked via deformation of the AA6061 alloy only. Thus, the CFRP-AA6061 joint is not restricted by the low ductility of CFRP. Initial hole-clinching tool shapes were determined based on the geometrical relationship between the hole-clinching tools and the interlocking shapes of the hole-clinched joint. The effect of process variables on the joinability of the hole-clinching process was investigated by FE-analysis. Based on the result of FE-analysis, the hole-clinched joint was designed with more than the required strength of 2.5 kN, as evaluated by performing a single lap shear test.

Similar content being viewed by others

Abbreviations

- F N , F S :

-

Joint strength under normal and shear loading

- T i :

-

Sheet thickness

- t N , t U :

-

Neck thickness of upper sheet and undercut

- k :

-

Shear yield stress of upper sheet

- k f :

-

Fracture stress of upper sheet

- X :

-

Bottom thickness of upper sheet

- H :

-

Die depth

- R H :

-

Hole radius of lower sheet

- S :

-

Punch stroke

References

Messler, R. W., “Trends in Key Joining Technologies for the Twenty-First Century,” Assembly Automation, Vol. 20, No. 2, pp. 118–128, 2000.

Lee, C. J., Kim, J. Y., Lee, S. K., Ko, D. C., and Kim, B. M., “Parametric Study on Mechanical Clinching Process for Joining Aluminum Alloy and High-Strength Steel Sheets,” Journal of Mechanical Science and Technology, Vol. 24, No. 1, pp. 123–126, 2010.

He, X., “Coefficient of Variation and its Application to Strength Prediction of Clinched Joints,” Advanced Science Letters, Vol. 4, No. 4–5, pp. 4–5, 2011.

Hwang, W. C., Lee, K. S., Yang, Y. J., and Yang, I. Y., “An Experimental Study on the Optimum Collapse Characteristics of Composite Structural Member under Impact Loading,” Int. J. Precis. Eng. Manuf., Vol. 12, No. 3, pp. 521–526, 2011.

Kim, W. K., Won, S. T., and Goo, B. C., “A study on Mechanical Characteristics of the Friction Stir Welded A6005-T5 Extrusion,” Int. J. Precis. Eng. Manuf., Vol. 11, No. 6, pp. 931–936, 2010.

Kim, S. C., Kim, J. S., and Yoon, H. J., “Experimental and Numerical Investigations of Mode I Delamination Behaviors of Woven Fabric Composites with Carbon, Kevlar and their Hybrid Fibers,” Int. J. Precis. Eng. Manuf., Vol. 12, No. 2, pp. 321–329, 2011.

Gomez, S., Onoro, J., and Pecharroman, J., “A Simple Mechanical Model of a Structural Hybrid Adhesive/Riveted Single Lap Joint,” International Journal of Adhesion and Adhesives, Vol. 27, No. 4, pp. 263–267, 2007.

Ueda, M., Miyake, S., Hasegawa, H., and Hirano, Y., “Instantaneous Mechanical Fastening of Quasi-Isotropic CFRP Laminates by a Self-Piercing Rivet,” Composite Structures, Vol. 94, No. 11, pp. 3388–3393, 2012.

Abe, Y., Matsuda, A., Kato, T., and Mori, K., “Plastic Joining of Aluminium Alloy and High Strength Steel Sheets by Mechanical Clinching,” Steel Research International, Vol. 79, pp. 649–656, 2008.

Ahn, N. S., Lee, C. J., Lee, J. M., Ko, D. C., Lee, S. B., and Kim, B. M., “Joining High-Strength Steel and Al6061 Sheet Using Hole Clinching Process,” Transactions of the Korean Society of Mechanical Engineers A, Vol. 36, No. 6, pp. 691–698, 2012.

Oudjene, M. and Ben-Ayed, L., “On the Parametrical Study of Clinch Joining of Metallic Sheets using the Taguchi Method,” Engineering Structures, Vol. 30, No. 6, pp. 1782–1788, 2008.

De Paula, A., Aguilar, M., Pertence, A., and Cetlin, P., “Finite Element Simulations of the Clinch Joining of Metallic Sheets,” Journal of Materials Processing Technology, Vol. 182, No. 1, pp. 352–357, 2007.

Mori, K., Abe, Y., and Kato, T., “Mechanism of Superiority of Fatigue Strength for Aluminium Alloy Sheets Joined by Mechanical Clinching and Self-Pierce Riveting,” Journal of Materials Processing Technology, Vol. 212, No. 9, pp. 1900–1905, 2012.

Varis, J. P., “The Suitability of Clinching as a Joining Method for High-Strength Structural Steel,” Journal of Materials Processing Technology, Vol. 132, No. 1, pp. 242–249, 2003.

American Society for Testing and Materials, “Standard Test Method for Tensile Properties of Polymer Matrix Composite Materials,” Document ID: D3039, 2008.

Bhushan, B., “Principles and Applications of Tribology,” John Wiley & Sons, pp. 554–558, 2013.

Cockcrof, M. G. and Latham, D. J., “Ducitility and Workability of Metals,” Journal of the Institute of Metals, Vol. 96, no. 2, pp. 33–39, 1968.

Lee, C. J., Kim, J. Y., Lee, S. K., Ko, D. C., and Kim, B. M., “Design of Mechanical Clinching Tools for Joining of Aluminium Alloy Sheets,” Materials & Design, Vol. 31, No. 4, pp. 1854–1861, 2010.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lee, CJ., Lee, SH., Lee, JM. et al. Design of hole-clinching process for joining CFRP and aluminum alloy sheet. Int. J. Precis. Eng. Manuf. 15, 1151–1157 (2014). https://doi.org/10.1007/s12541-014-0450-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12541-014-0450-6