Abstract

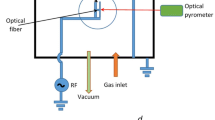

Electron beam cathodes have been used in various fields such as microscopy, X-ray tubes, welding, and surface modification. Generally, cathodes use metals with lower work function, higher thermal resistance, lower poisoning effects of gases, etc. LaB6, tungsten, and tantalum have normally been used as cathode materials with special materials coated if required. This study investigated the high-voltage plasma diode cathode for surface modifications of metal products such as polishing, hardening and heat treatment. The most fascinating features of this cathode are the high voltage and current that can be obtained at a low vacuum of a few mTorr. However, it is difficult to control the emission current to attain a steady state and to obtain higher brightness than that achieved using a thermal cathode. We studied the emission characteristics in terms of cathode and anode design parameters such as anode distance and cathode shape. Additionally, changes of emission characteristics are discussed in terms of the type of gas, pressure parameter, etc. using the emission resistance, effective breakdown voltage, and brightness. Finally, by measuring the change in surface roughness using the emitted electron beams, we found that the surface roughness values before the process were Ra=0.8 µm and Rz=5.4 µm, whereas those after the process were Ra=0.25 µm and Rz=2.3 µm. The electron beam polishing technology is eco-friendly and can minimize the emission of many harmful materials that arise when existing mechanical or electrochemical polishing technologies are used.

Similar content being viewed by others

Abbreviations

- d:

-

distance between the electrodes [cm]

- I 1 :

-

emission current [A]

- I 3 :

-

accelerated current [A]

- J :

-

current density [A/m2]

- γ se :

-

secondary electron emission coefficient

- n i :

-

density of incident ions

- P :

-

pressure [Torr]

- Pd :

-

pressure x distance between cathode and anode [Torr·cm]

- R e :

-

emission resistance [M]

- V a :

-

acceleration voltage [kV]

- V b :

-

breakdown voltage [kV]

- v i :

-

velocity of incident ions [m/s]

References

Kang, E. G., Kim, H. S., Kim, J. S., and Lee, S. W., “Development of High Density Electron Beam Source and Surface Finishing Characteristics”, Proc. of the KSPE Spring Conference, pp. 649–650, 2012.

Gao, Y. K., “Influence of Pulsed Electron Beam Treatment on Microstructure and Properties of TA5 Titanium Alloy”, Applied Surface Science, Vol. 264, pp. 633–635, 2013.

Matsumoto, I. and Furukawa, T., “Method and Device for Modifying Surface of Work by Electron Beam”, Sodick Co., Ltd., PCT/JP2006/311883, 2006.

Burdovitsin, V., Oks, E., Klimov, A., and Goreev, A., “Features of Ceramic Material Welding by Ribbon Electron Beam Under Fore-Vacuum Pressure”, Proc. of 10th Conference on Modification of Materials with Particle Beams and Plasma Flows, pp. 239–242, 2010.

Burdovitsin, V. A., Zhirkov, I. S., Oks, E. M., Osipov, I., and Fedorov, M., “A Plasma-Cathode Electron Source for Focused-Beam Generation in the Fore-Pump Pressure Range”, Instruments and Experimental Techniques, Vol. 48, No.6, pp. 761–763, 2005.

Goreev, A. K., Burdovitsin, V. A., Klimov, A. S., and Oks, E. M., “Electron Beam Welding of Ceramic to Metal using Fore-Vacuum Plasma Electron Source”, Inorganic Materials: Applied Research, Vol. 3, No.5, pp. 446–449, 2012.

Sari, A. H., Ghorannevis, M., Hora, H., and Osman, F., “Concave Cold Cathode Electron Gun using Obstructed Discharge”, Proc. of 31st EPS Conference on Plasma Physics, Vol. 28, 2004.

Fukao, M., Ishida, M., Ohtsuka, Y., and Matsuo, H., “A Simple Electron Gun by Obstructed Discharge and Its Discharge-Sustaining Mechanism”, Vacuum, Vol. 59, No.1, pp. 358–372, 2000.

Oks, E., “Plasma Cathode Electron Sources: Physics, Technology, Applications”, Wiley-VCH Verlag GmbH & Co. KGaA, 2006.

Oks, E., Brown, I., and Eremenko, V. A., “Emerging Applications of Vacuum-Arc-Produced Plasma, Ion, and Electron Beams”, Springer, pp. 173–225, 2002.

Lieberman, M. A. and Lichtenberg, A. J., “Principles of Plasma Discharges and Materials Processing”, John Wiley & Sons, pp.543–550, 2005.

Raizer, Y. P., “Gas Discharge Physics”, Springer, pp. 128–143, 1997.

Reiser, M., “Theory and Design of Charged Particle Beams”, John Wiley & Sons, pp. 543–550, 2005.

Okada, A., Uno, Y., McGeough, J., Fujiwara, K., Doi, K., et al., “Surface Finishing of Stainless Steels for Orthopedic Surgical Tools by Large-Area Electron Beam Irradiation”, CIRP Annals-Manufacturing Technology, Vol. 57, No.1, pp. 223–226, 2008.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kang, EG., Kim, JS., Lee, SW. et al. Emission characteristics of high-voltage plasma diode cathode for metal surface modification. Int. J. Precis. Eng. Manuf. 16, 13–19 (2015). https://doi.org/10.1007/s12541-014-0002-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12541-014-0002-8