Abstract

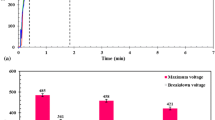

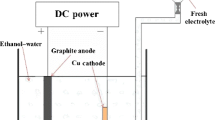

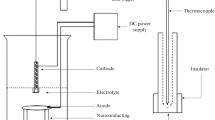

This paper describes the influence of the main factor on the colorful titanium oxide reacted film fabricated by EDM (Electrical Discharge machining). In our process, copper, together with pure titanium sheet, was used as anode and cathode (workpiece) respectively, and dielectric medium involved in the study was tap water. From the figures and tables shown, we can observe that colors of titanium oxide reacted films change with the increase of open voltages (0∼240) from yellow (10 V), purple (20 V), indigo (30 V), golden yellow (70 V), to peach (100 V), blue (130 V), yellow green (180 V), pink (240 V). The other open voltages produce mixed colors between those created by neighboring voltages. Moreover, XRD as well as EDS analysis have made it evident that the structure of the reacted film mentioned above is Ti2O other than TiO2 and the rise of pulse duration and interval will cause non-uniform color distribution. Compared with anodizing process, the Electrical Discharge machining approach we developed for generating colorful titanium oxide reacted film in the paper is much simpler, faster, cheaper and have plenty of advantages still in environment protection and hazard avoidance.

Similar content being viewed by others

Abbreviations

- Ra:

-

average surface roughness of workpiece

- Ton :

-

pulse duration in EDM process

References

Cotton, J. and Hayfield P., “Decorative finishes on titanium,” Transactions of the Institute of Metal Finishing, Vol. 45, pp 48–52, 1967.

Delplancke, J. L., Degrez, M., Fontana, A., and Winand, R., “Selfcolour anodizing of titanium,” Surface Technology, Vol. 16, No. 2, pp. 153–162, 1982.

Sonoda, T. and Kato, M., “Effects of discharge voltage on Ti-O film formation on Ti-6Al-4V alloy by reactive DC sputtering,” Thin Solid Films, Vol. 303, No. 1–2, pp. 196–199, 1997.

Martev, I. N., “Oxygen-ion-assisted deposition of TiO films,” Vacuum, Vol. 58, No. 2–3, pp. 327–334, 2000.

Pérez del Pino, A., Serra, P., and Morenza, J. L., “Oxidation of titanium through Nd:YAG laser irradiation,” Applied Surface Science, Vol. 197–198, pp. 887–890, 2002.

Pérez del Pino, A., Serra, P., and Morenza, J. L., “Coloring of titanium by pulsed laser processing in air,” Thin Solid Films, Vol. 415, No. 1–2, pp. 201–205, 2002.

Ohmori, H., Katahira, K., Mizutani, M., and Komotori, J., “Investigation on color-finishing process conditions for titanium alloy applying a new electrical grinding process,” CIRP Annals — Manufacturing Technology, Vol. 53, No. 1, pp. 455–458, 2004.

Masuzawa, T., “Machining characteristics of EDM using water as a dielectric fluid,” Proc. of the 22nd Machine Tool Design and Research Conference, pp. 441–447, 1981.

Minami, H., Masui, K., Tsukahara, H., and Hagino, H., “Coloring method of titanium alloy using EDM process,” Proc. of the 12th International Symposium for Electromachining (ISEM), pp. 503–512, 1998.

Minami, H., Masui, K., Tsukahara, H., and Hagino, H., “Coloring of titanium alloy using EDM process-Drawing with simple electrode,” Proc. of the 13th International Symposium for Electromachining (ISEM), pp. 589–599, 2001.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tsai, YY., Song, PL. & Fang, J.SC. Colorful oxide film formation on titanium by using EDM process. Int. J. Precis. Eng. Manuf. 14, 1933–1937 (2013). https://doi.org/10.1007/s12541-013-0262-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12541-013-0262-0