Abstract

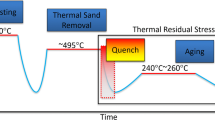

This study aims to predict the residual stress relieved by cryogenic heat treatment (CHT) of an Al6061 tube. Conventional CHT commonly consists of solid-solution heat treatment, uphill quenching, and artificial ageing. To produce a new residual stress that is opposite to the original in nature, the solid-solution heat-treated aluminum parts are usually immersed in LN2 during uphill quenching with conventional CHT, followed by rapid heating of the parts using boiling water or high-velocity steam. First of all, conventional T6 and CHT experiments are conducted to measure the temperature of a tube with dimensions Ø200 mm × h200 mm × t10 mm. Computational fluid dynamics (CFD) analysis is conducted to calculate the convective heat transfer coefficient and temperature of the tube. These results are compared with the temperature in the experiment, and the comparison results are used to predict residual stress by means of FE-simulation. In particular, the relaxation of residual stress during artificial ageing is investigated using the Zener-Wert-Avrami function with the user subroutine. The predicted values of residual stress are compared favorably with the experimental results within a deviation of 10–15%, in contrast to measurements obtained by micro-indentation and saw-cutting tests. In addition, the experimental results show that conventional CHT can relieve as much as 57% of the residual stress induced by the water quenching of conventional T6 heat treatment.

Similar content being viewed by others

References

Yang, R. T., Liao, H. T., Yang, Y. K., and Lin, S. S., “Modeling and optimization in precise boring processes for aluminum alloy 6061T6 components,” Int. J. Precis. Eng. Manuf., Vol. 13, No. 1, pp. 11–16, 2012.

Dolan, G. P. and Robinson, J. S., “Residual stress reduction in 7175-T73, 6061-T6 and 2017A-T4 aluminium alloys using quench factor analysis,” Journal of Materials Processing Technology, Vol. 153–154, No. 1–3, pp. 346–351, 2004.

Juijerm, P., Altenberger, I., and Scholtes, B., “Fatigue and residual stress relaxation of deep rolled differently aged aluminium alloy AA6110,” Materials Science and Engineering A, Vol. 426, No. 1–2, pp. 4–10, 2006.

Mitchell, I., “Residual stress reduction during quenching of wrought 7075 aluminum alloy,” Master’s Thesis, Department of Materials Science and Engineering, Worcester Polytechnic Institute, 2004.

Hossain, S., Truman, C. E., Smith, D. J., Peng, R. L., and Stuhr, U., “A study of the generation and creep relaxation of triaxial residual stresses in stainless steel,” International Journal of Solids and Structures, Vol. 44, No. 9, pp. 3004–3020, 2007.

Andrade-Campos, A., Neto da Silva, F., and Teixeira-Dias, F., “Modelling and numerical analysis of heart treatments on aluminium parts,” International Journal for Numerical Methods in Engineering, Vol. 70, No. 5, pp. 582–609, 2007.

Lior, N., “The cooling process in gas quenching,” Journal of Materials Processing Technology, Vol. 155–156, No. 1–3, pp. 1881–1888, 2004.

Hill, H. N., Barker, R. S., and Willey, L. A., ASM handbook. 52, pp. 657–674, 1960.

Wang, Q. C., Wang, L. T., and Peng, W., “Thermal stress relief in 7050 aluminum forgings by uphill quenching,” Materials Science Forum, Vol. 490–491, pp. 97–101, 2005.

Lados, D. A., Apelian, D., and Wang, L., “Minimization of residual stress in heat-treated Al-Si-Mg cast alloys using uphill quenching: Mechanisms and effects on static and dynamic properties,” Materials Science and Engineering A, Vol. 527, No. 13–14, pp. 3159–3165, 2010.

Berger, M. C. and Gregory, J. K., “Residual stress relaxation in shot peened Timetal 21s,” Materials Science and Engineering A, Vol. 263, No. 2, pp. 200–204, 1999.

Juijerm, P., Altenberger, I., and Scholtes, B., “Influence of ageing on cyclic deformation behavior and residual stress relaxation of deep rolled as-quenched aluminium alloy AA6110,” International Journal of Fatigue, Vol. 29, No. 7, pp. 1374–1382, 2007.

Croucher, T. and Associates, “A summary of the uphill quenching process,” http://www.croucher.us/uphill-quenching, 2010.

Jang, J. I., Son, D., Lee, Y. H., Choi, Y., and Kwon, D., “Assessing welding residual stress in A335 P12 steel welds before and after stress-relaxation annealing through instrumented indentation technique,” Scripta Materialia, Vol. 48, No. 6, pp. 743–748, 2003.

Lee, Y. H. and Kwon, D., “Estimation of biaxial surface stress by instrumented indentation with sharp indenters,” Acta Materialia, Vol. 52, No. 6, pp. 1555–1563, 2004.

Park, J. W. and Ferracane, J. L., “Measuring the residual stress in dental composites using a ring slitting method,” Dental Materials, Vol. 21, No. 9, pp. 882–889, 2005.

Prime, M. B. and Hill, M. R., “Residual stress, stress relief, and inhomogeneity in aluminum plate,” Scripta Materialia, Vol. 46, No. 1, pp. 77–82, 2002.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ko, DH., Ko, DC., Lim, HJ. et al. FE-simulation coupled with CFD analysis for prediction of residual stresses relieved by cryogenic heat treatment of Al6061 tube. Int. J. Precis. Eng. Manuf. 14, 1301–1309 (2013). https://doi.org/10.1007/s12541-013-0177-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12541-013-0177-9