Abstract

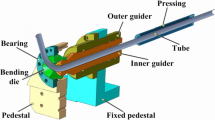

Aluminum alloys are widely used in the automotive industry to realize weight reductions. Extruded square tubes made from aluminum alloys show superior workability, and therefore, they are used as lightweight structural elements in various fields. To use such tubes in automobile parts, fabrication processes such as bending are necessary. However, bending can easily cause undesirable distortions such as thickness deviation and flattening. Generally, the use of a mandrel is considered to suppress these distortions effectively. However, studies have not yet established a bending technology for achieving highly accurate cross sections. This study aims to develop a press bending technology for obtaining tubes with highly accurate cross sections. First, we designed and developed a restraint jig for use in this bending process. A laminated mandrel was applied to the inside of the square tube and a constraint load was applied to the restraint plate on the outside to suppress cross-sectional deformation. The effect of the use of a mandrel and restraint plate on the bending of a square tube was experimentally investigated. Furthermore, the press bending process was analyzed through simulations using the finite element method (FEM).

Similar content being viewed by others

Abbreviations

- H0 :

-

Outer height of workpiece (mm)

- h0 :

-

Inner height of workpiece (mm)

- W0 :

-

Outer width of workpiece (mm)

- w0 :

-

Inner width of workpiece (mm)

- t0 :

-

Thickness of workpiece (mm)

- L0 :

-

Length of workpiece (mm)

- Rp :

-

Punch radius (mm)

- Rd :

-

Die radius (mm)

- Od :

-

Die opening (mm)

- CLh :

-

Clearance of height (mm)

- CLw :

-

Clearance of width (mm)

- P:

-

External force by spring (N)

- A:

-

Contact area of workpiece and restraint plate (mm2)

- T:

-

Restraint load factor

- PT :

-

Circumferential force of tension side

- PC :

-

Circumferential force of compression side

- PTN :

-

Flattening component of tension side

- PCN :

-

Flattening component of compression side

References

Hasegawa, O., Manabe, K., and Nishimura. H., “Effects of Wing-Type Die in Press Bending of Aluminum Alloy Extruded Shapes,” Journal of Japan Institute of Light Metals, Vol. 57, No. 6, pp. 245–249, 2007.

Hasegawa, O. and Nishimura, H., “Workability and Cross-Sectional Deformation in Press Bending of 6000 Alloy Extruded Shapes,” Journal of Japan Institute of Light Metals, Vol. 46, No. 5, pp. 243–248, 1995.

Utsumi, N. and Sakaki, S., “Method of Draw Bending Process Preventing Undesirable Deformation of Aluminum Extruded,” Alutopia, Vol. 29, No. 2, pp. 19–24, 1999.

Utsumi, N. and Sakaki, S., “Countermeasures Against Undesirable Phenomena in The Draw-Bending Process for Extruded Square Tubes,” Journal of Material Processing Technology, Vol. 123, pp. 264–269, 2002.

Fuchs, F. J., “Waveguide Bending Design Analysis: Theory of Bending and Formulae for Determination of Wall Thicknesses,” The Bell System Technical Journal, Vol. 38, No. 6, pp. 1457–1484, 1959.

Gangyao, Z., Yuli, L., and He, Y., “Effect of Clearance on Wrinkling of Thin-Walled Rectangular Tube in Rotary Draw Bending Process,” The International Journal of Advanced Manufacturing Technology, Vol. 50, No. 1–4, pp. 85–92, 2010.

Jeong, H.-S., Jeon, J.-W., Ha, M.-Y., and Cho, J.-R., “Finite element analysis for inconel 625 fine tube bending to predict deformation characteristics,” Int. J. Precis. Eng. Manuf., Vol. 13, No. 8, pp. 1395–1401, 2012.

The Japan Institute of Light Metals, “Accuracy and Limitations of Extruded Square Tube Aluminum Alloy 6061 and 6063 in Bending,” No. 36, pp. 5–14, 1996.

Sakaki, S. and Utsumi, N., “Factors Causing Undesirable Deformations During The Bending of Extruded Sections,” Materials Transactions, Vol. 47, No. 5, pp. 1354–1359, 2006.

The Japan Society for Technology of Plasticity, “Tube Forming-Forming Technology and Products Design,” Corona Publishing Co., Ltd., p. 51, 1992.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Nakajima, K., Utsumi, N. & Yoshida, M. Suppressing method of the cross section deformation for extruded square tubes in press bending. Int. J. Precis. Eng. Manuf. 14, 965–970 (2013). https://doi.org/10.1007/s12541-013-0127-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12541-013-0127-6