Abstract

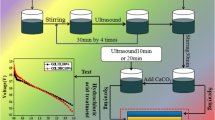

Proton exchange membrane fuel cell (PEMFC), also known as polymer electrolyte membrane fuel cell, is the type of fuel cell being developed for transport applications as well as for stationary and portable applications. Typical PEMFC consists of several essential components, and gas diffusion layer is considered to be one of the most important components. Gas diffusion layer (GDL) in PEMFC works as a protective layer for the delicate catalyst structure, provides good mechanical strength and easy gas access to the catalyst, and improves the electrical conductivity. Consequently, GDL of PEMFC should have low electronic resistivity, specific surface to enhance good electronic contact and proper hydrophobicity for each application. The properties of the conventional GDL’s can be improved by implementing microporous layer instead of common thick porous support layer. Microporous layer (MPL) reduces the contact resistance between catalyst layer and macroporous substrate. The main purpose of using MPL is the water management, as they provide effective wicking of water from the cathode catalyst layer into the diffusion media, thus improving the overall performance of the PEMFC. In this study, the fabrication of GDL containing microporous layer (MPL) made from the slurry of FEP (Flourinated Ethylene Prophylene) mixed with carbon black was investigated in detail. The properties of FEP, such as low friction and nonreactivity, are same as those of PTFE; however FEP has few advantageous points than PTFE. FEP can be formed into desired shapes more easily; its softer than PTFE (melting temperature of FEP is 260°C); it is highly transparent and resistant to sunlight. The microstructure of the developed GDL containing MPL was analyzed by SEM/EDX by observing the surface and cross section of the specimen. The properties such as viscosity, electric conductivity, density, porosity were measured. The amount of carbon loading to get optimum thickness was defined, and the performance of the fuel cell using developed GDL with MPL was evaluated.

Similar content being viewed by others

References

Quick, C., Ritzinger, D., Lehnert, W., and Hartnig, C., “Characterization of water transport in gas diffusion media,” J. Power Sources, Vol. 190, No. 1, pp. 110–1201, 2009.

Yan, W.-M., Hsueh, C.-Y., Soong, C.-Y., Chen, F., Cheng, C.-H., and Mei, S.-C., “Effects of fabrication processes and material parameters of GDL on cell performance of PEM fuel cell,” International Journal of Hydrogen Energy, Vol. 32, No. 17, pp. 4452–4458, 2007.

Chen-Yang, Y. W., Hung, T. F., Huang, J., and Yang, F. L., “Novel single-layer gas diffusion layer based on PTFE/carbon black composite for proton exchange membrane fuel cell,” J. Power Sources, Vol. 173, No. 1, pp. 183–188, 2007.

Liu, C.-H., Ko, T.-H., Shen, J.-W., Chang, S.-I., Chang, S.-I., and Liao, Y.-K., “Effect of hydrophobic gas diffusion layers on the performance of the polymer exchange membrane fuel cell,” J. Power Sources, Vol. 191, No. 2, pp. 489–494, 2009.

Kannan, A. M., Sadananda, S., Parker, D., Munukutla, L., Wertz, J., and Thommes, M., “Wire rod coating process of gas diffusion layers fabrication for proton exchange membrane fuel cells,” J. Power Sources, Vol. 178, No. 1, pp. 231–237, 2008.

Jordan, L. R., Shukla, A. K., Behrsing, T., Avery, N. R., Muddle, B. C., and Forsyth, M., “Diffusion layer parameters influencing optimal fuel cell performance,” J. Power Sources, Vol. 86, pp. 250–254, 2000.

Wang, X. L., Zhang, H. M., Zhang, J. L., Xu, H. F., Tian, Z. Q., Chen, J., Zhong, H. X., Liang, Y. M., and Yi, B. L., “Microporous layer with composite carbon black for PEM fuel cells,” Electrochimica Acta, Vol. 51, No. 23, pp. 4909–4915, 2006.

Giordano, N., Passalacqua, E., Alderucci, V., Staiti, P., Pino, L., Mirzaian, H., Taylor, E. J., and Wilemski, G., “Morphological characteristics of PTFE bonded gas diffusion electrodes,” Electrochimica Acta, Vol. 36, No. 5–6, pp. 1049–1055, 1991.

Poornesh, K. K., Lee, S.-K., Cho, C., and Choi, K.-W., “Effect of bipolar plate materials on the stress distribution and interfacial contact resistace in PEM fuel cell,” Int. J. Precis. Eng. Manuf., Vol. 11, No. 1, pp. 583–588, 2010.

Kim, J.-S., Park, J.-B., Kim, Y.-M., Ahn, S.-H., Sun, H.-Y., Kim, K.-H., and Song, T.-W., “Fuel Cell End Plates: A review,” Int. J. Precis. Eng. Manuf., Vol. 9, No. 1, pp. 39–46, 2008.

Park, J.-Y., Kim, H.-T., Lee, E. S., Son, I.-H., and Han, S., “Effect of the porous carbon layer in the cathode gas diffusion media on direct methanol fuel cell performances,” International Journal of Hydrogen Energy, Vol. 34, No. 19, pp. 8257–8262, 2009.

Wang, X. L., Zhang, H. M., Zhang, J. L., Xu, H. F., Tian, Z. Q., Chena, J., Zhong, H. X., Liang, Y. M., and Yi, B. L., “Microporous layer with composite carbon black for PEM fuel cells,” Electrochimica Acta, Vol. 51, pp. 4909–4915, 2006.

Grigoriev, S. A., Kalinnkov, A. A., Fateev, V. N. and Wragg, A. A., “Numerical optimization of bipolar plates and gas diffusion layers for PEM fuel cell,” J. Applied Electrochemistry, Vol. 36, pp. 991–996, 2006.

Lin, J.-H., Chen, W.-H., Su, Y.-J., and Ko, T.-H., “Performance Analysis of a Proton-Exchange Membrane Fuel Cell (PEMFC) with Various Hydrophobic Agents in a Gas Diffusion Layer,” Energy & Fuels, Vol. 22, pp. 1200–1203, 2008.

Liu, C.-H., Ko, T.-H., Shen, J.-W., Chang, S.-I., Chang, S.-I., and Liao, Y.-K., “Effect of hydrophobic gas diffusion layers on the performance of the polymer exchange membrane fuel cell,” J. Power Sources, Vol. 191, pp. 489–494, 2009.

Dicks, A. L., “The role of carbon in fuel cells,” J. Power Sources, Vol. 156, pp. 128–141, 2006.

Hung, T. F., Huang, J., Chuang, H. J., Bai, S. H., Lai, Y. J., and Chen-Yang, Y. W., “Highly efficient single-layer gas diffusion layers for the proton exchange membrane fuel cell,” J. Power Sources, Vol. 184, No. 1, pp. 165–171, 2008.

Lee, W.-K., Ho, C.-H., Van Zee, J. W., and Murthy, M., “The effects of compression and gas diffusion layers on the performance of a PEM fuel cell,” J. Power Sources, Vol. 84, No. 1, pp. 45–51, 1999.

Zhou, T. and Liu, H., “Effects of the electrical resistances of the GDL in a PEM fuel cell,” J. Power Sources, Vol. 161, pp. 444–453, 2006.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Park, S.B., Park, Yi. Fabrication of gas diffusion layer (GDL) containing microporous layer using flourinated ethylene prophylene (FEP) for proton exchange membrane fuel cell (PEMFC). Int. J. Precis. Eng. Manuf. 13, 1145–1151 (2012). https://doi.org/10.1007/s12541-012-0152-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12541-012-0152-x