Abstract

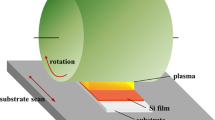

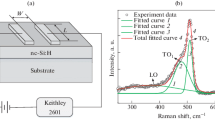

We have developed a high frequency (40 MHz) plasma-enhanced chemical vapor deposition (PECVD) system for large-area and high-rate deposition of hydrogenated microcrystalline silicon (μc-Si:H). The large-area and high-rate deposition is known to be the key for mass production of silicon thin film solar cells, and the high-power operation made it possible to obtain deposition rates up to 1.8 nm/s. However, it was reported that there were several drawbacks, and temperature was typically concerned by many researchers. The temperature is one of the most important factors in μc-Si:H deposition processes using PECVD for the reason that temperature is in charge of the surface reaction and the growth kinetics. Without cooling, the temperature was observed to increase considerably during deposition of a thick intrinsic layer with thickness of 2 μm. In order to operate PECVD processes with constant temperature, it is required to design an efficient temperature control system. We have developed a cooling system which is designed for a susceptor and a showerhead. Susceptor cooling is performed in a direct cooling mode where a coolant is circulated through a tube inside a susceptor, and appropriate flow rates and temperatures of the coolant were calculated. Showerhead cooling system is designed to make use of an indirect cooling mode where there is efficient thermal radiation heat exchange between a showerhead and chamber wall. The efficiency was substantially improved by anodizing surface of a showerhead. This cooling system allows stable processes of large-area μc-Si:H deposition at high power.

Similar content being viewed by others

References

Hamakawa, Y., “Thin-film solar cells: Next generation photovoltaic sans its applications,” Springer, 2004.

Keppner, H., Meier, J., Torres, P., Fischer, D., and Shah, A., “Microcrystalline silicon and micromorph tandem solar cells,” Appl. Phys. A, Vol. 69, No. 2, pp. 169–177, 1999.

Lee, J., Hwang, J.-H., Lee, S. W., Park, S., Shin, S., and Chung, H., “Application of nano-pulsed Nd: YAG laser to crystallization of amorphous Si thin films for next generation flat-panel display,” Int. J. Precis. Eng. Manuf., Vol. 13, No. 4, pp. 587–591, 2012.

Van den Donker, M. N., Schmitz, R., Appenzeller, W., and Rech, B., “The role of plasma induced substrate heating during high rate deposition of microcrystalline silicon solar cells,” Thin Solid Films, Vol. 511–512, pp. 562–566, 2006.

Niikura, C., Kondo, M., and Matsuda, A., “Preparation of microcrystalline silicon films at ultra high-rate of 10 nm/s using high-density plasma,” Journal of Non-Crystalline Solids, Vol. 338–400, pp. 42–46, 2004.

Grote, K.-H. and Antonsson, E. K., “Handbook of Mechanical Engineering,” Springer, 2009.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lim, Y.B., Hwang, D.S., Lee, J.O. et al. Design of cooling system for large-area and high-rate deposition of hydrogenated microcrystalline silicon. Int. J. Precis. Eng. Manuf. 13, 1137–1140 (2012). https://doi.org/10.1007/s12541-012-0150-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12541-012-0150-z