Abstract

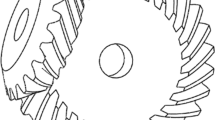

In recent years, there is a trend that lower gear noise levels are demanded for drivers to avoid annoyance and fatigue during operation. For the manual transaxle, meshing transmission error (T.E.) is the excitation that leads to the tonal noise known as gear whine, and radiated gear whine is also the dominant source of noise in the whole gearbox. This paper presents a method for the various interaction analysis of gear tooth profile and lead crowning modification, and the prediction of transmission error under the loaded torques for the 3rd gear pairs of two proposalsin the manual transaxle. And transmission error, root stress and contact stress are also calculated and compared before and after tooth micromodification under one torque. At last, the gear whine noise of the 3rd gear in WOT (Wide Open Throttle) and the coasting operation condition is investigated and compared between the two proposals. The simulation and test show that the transmission error and contact stress under the loaded torque can be minimized by the appropriate tooth modification. It is a good approach which the simulated result is used to improve the design in order to minimize the radiation gear whine noise.

Similar content being viewed by others

References

Houser, D. R., Harianto, J., and Ueda, Y., “Determining the Source of Gear Whine Noise,” Gear Solutions, pp. 16–23, 2004.

Neusser, Z., Sopouch, M., Schaffner, T., and Priebsch, H., “Multi-body Dynamics Based Gear Mesh Models for Prediction of Gear Dynamics and Transmission Error,” SAE Paper, No. 2010-01-0897, 2010.

Zhou, C. S., Young, S. B., and Tang, Y. W., “Two-stage Gear Driveline Vibration and Noise,” SAE Paper, No. 2011-01-1542, 2011.

Harianto, J. and Houser, D. R., “A Methodology for Obtaining Optimum Gear Tooth Micro-Topographies for Noise and Stress Minimization Over a Broad Operating Torque Range,” Proc. of the ASME International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, Paper No. DETC2007-34655, pp. 289–303, 2007.

Cho, M. and Kim, C., “Dynamic Analyses of Fluctuating Bearing Forces on Worm Gears of Speed Reducers,” Int. J. Precis. Eng. Manuf., Vol. 13, No. 2, pp. 193–199, 2012.

Lee, Y. J. and Lee, S. K., “Classification of Noise Sources in a Printer and Its Application to the Development of Sound Quality Evaluation,” Int. J. Precis. Eng. Manuf., Vol. 13, No. 4, pp. 491–499, 2012.

Welbourn, D. B., “Fundamental Knowledge of Gear Noise — A Survey,” Inst. Mech. Eng. Conf. on Noise and Vibration of Engines and Transmissions, pp. 9–14, 1979.

Sigg, H., “Profile and Longitudinal Corrections on Involute Gears,” AGMA, 1965.

Conry, T. F. and Seireg, A., “A Mathematical Programming Technique for the Evaluation of Load Distribution and Optimal Modifications for Gear Systems,” J. of Engineering for Industry, Vol. 95, pp. 1115–1122, 1973.

Ohio State University, GearLab, “Load Distribution Program Manual,” 2002.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, Q., Kang, J., Dong, W. et al. A study on tooth modification and radiation noise of a manual transaxle. Int. J. Precis. Eng. Manuf. 13, 1013–1020 (2012). https://doi.org/10.1007/s12541-012-0132-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12541-012-0132-1