Abstract

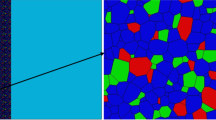

Ti(C,N)-based cermets were recently designed for tool applications as they offer enhanced interfacial strength. Such a cermet exhibits a typical core/rim microstructure as found in conventional cermets. To determine the possibility of using new cermet as a cutting tool, Ti(C,N) along with various carbides, nitrides, solid-solution carbonitride such as (Ti,W)(C,N), and Ni were milled together, sintered into the size of SNGN120408 and used in turning the SM45C (AISI45). Commercial WC and cermet insert of an identical size were selected to compare its cutting capability with that of the home-made cermet tool. To ensure a fair comparison of the cutting performance, the optimal machining conditions for commercial WC, cermet and home-made cermet tools were obtained using the Taguchi method. Experiments under both optimal conditions showed the excellent cutting performance of the new home-made cermet tool. It is believed that the interface between core Ti(C,N) and rim phases has been improved significantly in the new cermets.

Similar content being viewed by others

Abbreviations

- WC:

-

Tungsten Carbide

- Ti(C,N):

-

Titanium Carbonitride

References

Dobrzanski, L. A., Golombek, K., Kopac, J., and Sokovic, M., “Effect of depositing the hard surface coating on properties of the selected cemented carbide and tool cermets,” J. Mat. Proc. Tech., Vol. 157–158, pp. 304–311, 2004.

Zhang, X., Liu, N., Yang, H., and Zheng, Y., “Boronizing of nano-TiN modified TiC-based cermets,” Int. J. Refrac. Met. Hard Mater., Vol. 27, No. 3, pp. 653–658, 2009.

He, H.-B., Li, H.-Y., Xu, Z.-Z., Kim, D., and Lyu, S.-K., “Effect of MoS2-Based Composite Coatings on Tribological Behavior and Efficiency of Gear,” Int. J. Precis. Eng. Manuf., Vol. 11, No. 6, pp. 937–943, 2010.

Dizaji, V. R., Rahmani, M., Sani, M. F., Nemati, Z., and Akbari, J., “Microstructure and cutting performance investigation of Ti(C, N)-based cermets containing various types of secondary carbides,” Int. J. Mach. Tools Manuf., Vol. 47, No. 5, pp. 768–772, 2007.

Kwon, W. T., Park, J. S., Kim, S.-W., and Kang, S., “Effect of WC and group IV carbides on the cutting performance of Ti(C,N) cermet tools,” Int. J. Mach. Tools Manuf., Vol. 44, No. 4, pp. 341–346, 2004.

Liu, N., Chao, S., and Yang, H., “Cutting performances, mechanical property and microstructure of ultra-fine grade Ti(C, N)-based cermets,” Int. J. Refrac. Met. Hard Mater., Vol. 24, No. 6, pp. 445–452, 2006.

Liu, N., Xu, Y. D., Li, H., Chen, M. H., Zhou, J., Xie, F., and Yang, H. D., “Cutting and wearing characteristics of TiC-based cermets cutters with nano-TiN addition,” J. Mat. Proc. Tech., Vol. 161, No. 3, pp. 478–484, 2005.

Ko, Y.-M., Kwon, W. T., and Kim, Y.-W., “Cutting performance of Al2O3-SiC nanocomposite tools,” J. Mat. Sci., Vol. 40, No. 3, pp. 785–787, 2005.

D’Errico, G. E., Calzavarini, R., and Vicenzi, B., “Influence of PVD coatings on cermet tool life in continuous and interrupted turning,” J. Mat. Proc. Tech., Vol. 78, No. 1–3, pp. 53–58, 1998.

Ahn, S. Y. and Kang, S., “Formation of core/rim structure in Ti(C,N)-WC-Ni cermets via a dissolution and precipitation process,” J. Am. Ceram. Soc., Vol. 83, No. 6, pp. 1489–1494, 2000.

Lee, H. W. and Kwon, W. T., “Determination of the minute range for RSM to select the optimum cutting conditions during turning on CNC lathe,” J. Mech. Sci. Tech., Vol. 24, No. 8, pp. 1637–1645, 2010.

Phadke, M. S., “Quality engineering using robust design,” Prentice Hall, 1989.

Qi, F. and Kang, S., “A study on microstructural changes in Ti(CN)-NbC-Ni cermets,” Mater. Sci. Eng. A, Vol. 251, No. 1–2, pp. 276–285, 1998.

Kim, S. W., Min, K. H., and Kang, S., “Rim structure in Ti(C0.7N0.3)-WC-Ni cermets,” J. Am. Ceram. Soc., Vol. 86, No. 10, pp. 1761–1766, 2003.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kim, YS., Kwon, W.T., Seo, M. et al. Tool performance of new wear-resistant cermets. Int. J. Precis. Eng. Manuf. 13, 941–946 (2012). https://doi.org/10.1007/s12541-012-0122-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12541-012-0122-3