Abstract

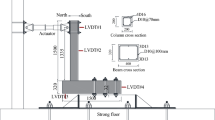

In this study, in order to replace the conventional steel bogie with a composite bogie, a composite side beam made of glass/epoxy was developed to be used in the bogie frame of an urban subway train. The composite side beam was manufactured using two different manufacturing method; autoclave curing method and resin transfer moulding method (RTM). And, then, they were tested under a vertical load of 140 kN to evaluate the structural behavior. Moreover, the stress and strain distribution was evaluated with the finite element method and compared with the experiment. The maximum deflections of the two side beam were 7.74 mm and 8.25 mm, respectively. The side beam made by RTM appeared a little softer than the autoclave cured one due to the lower fiber volume fraction. Through the parametric study for the different design parameters, it was known that the variation of the side beam height appeared to be strongest effect to deflection.

Similar content being viewed by others

References

Kim, J. S., Lee, S. J. and Shin, K. B., “Manufacturing and Structural Safety Evaluation of a Composite Train Carbody,” Compos. Struct., Vol. 78, No. 4, pp. 468–476, 2007.

Kim, J. S., “Development of a User-Friendly Expert System for Composite Laminate Design,” Compos. Struct., Vol. 79, No. 1, pp. 76–83, 2007.

Kim, J. S. and Jeong, J. C., “Natural Frequency Evaluation of a Composite Train Carbody with Length of 23 m,” Compos. Sci. Technol., Vol. 66, No. 13, pp. 2272–2283, 2006.

Kim, J. H., Shin, K. B. and Kim, J. S., “Optimum design on suspension joint parts of GFRP composite bogie frame with Hshaped side beams for urban railway trains,” Int. J. Precis. Eng. Manuf., Vol. 13, No. 1, pp. 71–76, 2012.

Kim, J. S., “Fatigue Assessment of Tilting Bogie Frame for Korean Tilting Train: Analysis and Static Tests,” Eng. Fail. Anal., Vol. 13, No. 8, pp. 1326–1337, 2006.

Geuenich, W., Guenther, C. and Leo, R., “Dynamics of Fiber Composite Bogies with Creep-controlled Wheelsets,” Proc. of the 8th IAVSD Symposium, pp. 225–238, 1983.

Guenther, C., Leo, R. and Wackerle, P., “New Technologies for Rail Vehicle Bogies and Car Body Substructures,” MRS, pp. 89–95, 1985.

Leo, R. and Lang, H. P., “Fiber-composite Bogies on Test,” Railway Gazette International, pp. 632–633, 1986.

Maurin, L., Boussoir, J., Rougeault, S., Bugaud, M., Ferdinand, P., Landrot, A. G., Grunevald, Y.-H. and Chauvin, T., “FBGbased Smart Composite Bogies for Railway Applications,” 15th Optical Fiber Sensors Conference Technical Digest, Vol. 1, pp. 91–94, 2002.

Shankar Shiva, G. S. and Vijayarangan, S., “Mono Composite Leaf Spring for Light Weight Vehicle — Design, End Joint Analysis and Testing,” Materials Science, Vol. 12, No. 3, pp. 220–225, 2006.

Al-Qureshi, H. A., “Automobile Leaf Springs from Composite Materials,” J. Mater. Proc. Technol., Vol. 118, No. 1, pp. 58–61, 2001.

Rajendran, I. and Vijayarangan, S., “Optimal Design of a Composite Leaf Spring using Genetic Algorithms,” Comput. Struct., Vol. 79, No. 11, pp. 1121–1129, 2001.

Simulia, “ABAQUS user’s manual,” 2007.

Seong, M. S., Kim, T. W., Nguyen, K. H., Kweon, J. H. and Choi, J. H., “A parametric study on the failure of bonded singlelap joints of carbon composite and aluminum,” Compos. Struct., Vol. 86, No. 1–3, pp. 135–145, 2008.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kim, JS., Lee, WG. Manufacturing and structural behavior evaluation of composite side beams using autoclave curing and resin transfer moulding method. Int. J. Precis. Eng. Manuf. 13, 723–730 (2012). https://doi.org/10.1007/s12541-012-0094-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12541-012-0094-3