Abstract

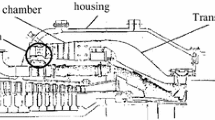

Gas turbine engines are being widely used for power generation recently because of their high efficiency and versatility. However, it is occasionally reported that a gas turbine under normal operation fails even though careful inspections were scheduled. In this paper, the recent failure of the gas turbines of a cogeneration plant is analyzed by focusing mainly on the crack initiation mechanism of blade fracture. Damage of several blades of the compressor was observed after a gas turbine was disassembled, and the root causes of the damage were investigated in detail by scanning electron microscopy as well as optical microscopy. The defects observed at the crack initiation site have been characterized by comparison with previous studies. The fracture of the blade was supposed to be initiated by a crack due to concentrated stresses around a preexisting defect which was possibly formed before the turbine was operated, e.g., a forging defect during the three-step forging process for blades manufacture.

Similar content being viewed by others

Abbreviations

- a:

-

the depth of polishing from the suction side to observe the cross section of the crack

References

Pilavachi, P. A., “Power Generation with Gas Turbine Systems and Combined Heat and Power,” Appl. Therm. Eng., Vol. 20, No. 15–16, pp. 1421–1429, 2000.

Wu, D. W. and Wang, R. Z., “Combined Cooling, Heating and Power: A Review,” Progress in Energy and Combustion Science, Vol. 32, No. 5–6, pp. 459–495, 2006.

Koul, A. K. and Castillo, R., “Assessment of Service Induced Microstructural Damage and Its Rejuvenation in Turbine Blades,” Metall. Mater. Trans. A, Vol. 19, No. 8, pp. 2049–2066, 1998.

Cowles, B. A., “High Cycle Fatigue in Aircraft Gas Turbines — an Industry Perspective,” Int. J. Fracture, Vol. 80, No. 2–3, pp. 147–163, 1996.

Eliaz, N., Shemesh, G. and Latanision, R. M., “Hot Corrosion in Gas Turbine Components,” Eng. Fail. Anal., Vol. 9, No. 1, pp. 31–43, 2002.

Chang, J. C., Yun, Y. H., Choi, C. and Kim, J. C., “Failure Analysis of Gas Turbine Buckets,” Eng. Fail. Anal., Vol. 10, No. 5, pp. 559–567, 2003.

Hou, J., Wicks, B. J. and Antoniou, R. A., “An Investigation of Fatigue Failures of Turbine Blades in a Gas Turbine Engine by Mechanical Analysis,” Eng. Fail. Anal., Vol. 9, No. 2, pp. 201–211, 2002.

Arakere, N. K. and Swanson, G., “Effect of Crystal Orientation on Fatigue Failure of Single Crystal Nickel Base Turbine Blade Superalloys,” J. Eng. Gas Turb. Power, Vol. 124, No. 1, pp. 161–176, 2002.

Yoon, W. N., Kim, J. S., Kang, M. S. and Kim, D. N., “Development of Crack Detection Method at Steam Turbine Blade Root Finger using Ultrasonic Test,” J. of the KSPE, Vol. 28, No. 6, pp. 738–744, 2011.

Carter, T. J., “Common Failures in Gas Turbine Blades,” Eng. Fail. Anal., Vol. 12, No. 2, pp. 237–247, 2005.

Mazur, Z., Luna-Ramirez, A., Juarez-Islas, J. A. and Campos-Amezcua, A., “Failure Analysis of a Gas Turbine Blade Made of Inconel 738LC Alloy,” Eng. Fail. Anal., Vol. 12, No. 3, pp. 474–486, 2005.

Verhees, M. L. J., “Experimental Modal Analysis of a Turbine Blade,” Technische Universiteit Eindhoven, Traineeship Report, DCT 2004.120, 2004.

Cha, D.-J., Kim, D.-K., Cho, J.-R. and Bae, W.-B., “Hot Shape Forging of Gas Turbine Disk Using Microstructure Prediction and Finite Element Analysis,” Int. J. Precis. Eng. Manuf., Vol. 12, No. 2, pp. 331–336, 2011.

He, M. L., “Metallographic Interpretation of Steel Forging Defects,” Microsc. Microanal., Vol. 13, pp. 1050–1051, 2007.

Fujikawa, S. and Ishii, K., “Diagnostic Expert Systems for Defects in Forged Parts,” J. Intell. Manuf., Vol. 6, No. 3, pp. 163–173, 1995.

British Energy, “HPB: Examination of the Fractured Stage Front Blade from the ex-T/A 8 LP2 Rotor,” Engineering Advance Note No. E/EAN/BDDB/0159/HPB/06, 2006.

Gallardo, J. M., Rodriguez, J. A. and Herrera, E. J., “Failure of gas turbine blades,” Wear, Vol. 252, No. 3–4, pp. 264–268, 2002.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yoon, W.N., Kang, M.S., Jung, N.K. et al. Failure analysis of the defect-induced blade damage of a compressor in the gas turbine of a cogeneration plant. Int. J. Precis. Eng. Manuf. 13, 717–722 (2012). https://doi.org/10.1007/s12541-012-0093-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12541-012-0093-4