Abstract

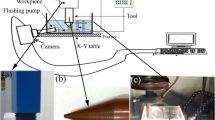

Dry EDM is an emerging EDM technology, which uses gas as dielectric fluid. Due to low density of gaseous dielectric, the process experiences i) unconstrained plasma expansion thereby reducing the effective material removal rate (MRR) and ii) inefficient disposal of debris. This work proposes use of electrodes with peripheral slots to provide more space for the flow of dielectric for effective debris disposal and consequently improve MRR. In this regard, a comprehensive experimentation using Taguchi L16 orthogonal array has been planned initially to optimize the number of peripheral slots on the electrodes, and then to understand the effect of the slots on material removal, tool wear, oversize and depth achieved as a function of processing conditions. It is observed that the optimum number of peripheral slots on electrode for effective debris evacuation is four for the electrode configuration used in this work. The statistical analysis shows that in dry EDM, discharge current (I), gap voltage (V), rotational speed (N) and pulse off-time (Toff) control MRR. Also, use of slotted electrodes significantly reduces the electrode wear rate, and attachment of debris particles on the electrodes.

Similar content being viewed by others

References

Kunieda, M., Yoshida, M. and Taniguchi, N., “Electrical discharge machining in gas,” CIRP Annals — Manufacturing Technology, Vol. 46, No. 1, pp. 143–146, 1997.

Zhang, Q. H., Zhang, J. H., Deng, J. X., Qin, Y. and Niu, Z. W., “Ultrasonic vibration electrical discharge machining in gas,” Journal of Materials Processing Technology, Vol. 129, No. 1–3, pp. 135–138, 2002.

Tao, J., Shih, A. J. and Ni, J., “Experimental study of the dry and near dry electrical discharge milling processes,” Journal of Manufacturing Science and Engineering, Vol. 130, No. 1, pp. 1–8, 2008.

Kao, C. C., Tao, J. and Shih, A. J., “Near dry electrical discharge machining,” International Journal of Machine Tools and Manufacture, Vol. 47, No. 15, pp. 2273–2281, 2007.

Kunieda, M., Miyoshi, Y., Takaya, T., Nakajima, N., ZhanBo, Y. and Yoshida, M., “High speed 3D milling by dry EDM,” CIRP Annals — Manufacturing Technology, Vol. 52, No. 1, pp. 147–150, 2003.

Yu, Z., Jun, T. and Kunieda, M., “Dry electrical discharge machining of cemented carbide,” Journal of Materials Processing Technology, Vol. 149, No. 1–3, pp. 353–357, 2004.

Tao, J., Shih, A. J. and Ni, J., “Near-dry EDM milling of mirror-like surface finish,” International Journal of Electrical Machining, Vol. 13, No. 1, pp. 29–33, 2008.

Saha, S. K. and Choudhury, S. K., “Experimental investigation and empirical modeling of the dry electric discharge machining process,” International Journal of Machine Tools and Manufacture, Vol. 49, No. 3–4, pp. 297–308, 2009.

Phadke, M. S., “Quality Engineering using Robust Design,” Prentice Hall Publication, New Jersey, pp. 149, 280–285,1989.

Govindan, P. and Joshi, S. S., “Experimental characterization of material removal in dry electrical discharge drilling,” International Journal of Machine Tools and Manufacture, Vol. 50, No. 5, pp. 431–443, 2010.

Dhar, S., purohit, R., Saini, N., Sharma, A. and Kumar, G. H., “Mathematical modeling of electric discharge machining of cast Al-4Cu-6Si alloy-10 wt.% SiCp composites,” Journal of Materials Processing Technology, Vol. 194, No. 1–3, pp. 24–29, 2007.

Yoo, B. H., Min, B. K. and Lee, S. J., “Analysis of machining characteristics of EDM as functions of the mobilities of electrons and ions,” Int. J. Precis. Eng. Manuf., Vol. 11, No. 4, pp. 629–632, 2010.

Chung, D. K., Shin, H. S., Park, M. S. and Chu, C. M., “Machining characteristics of micro-EDM in water using high frequency bipolar pulse,” Vol. 12, No. 2, pp. 195–201, 2011.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Puthumana, G., Joshi, S.S. Investigations into performance of dry EDM using slotted electrodes. Int. J. Precis. Eng. Manuf. 12, 957–963 (2011). https://doi.org/10.1007/s12541-011-0128-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12541-011-0128-2