Abstract

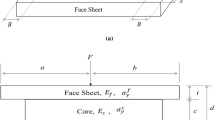

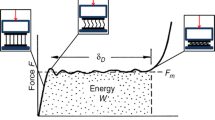

The deformation behavior and stress-strain relationships for a lightweight sandwich plate in the elastic regions are mainly dependent on the elastic properties of the core in the sandwich plate. The aim of this paper is to determine experimentally the elastic properties of a core in a thin sandwich plate with a metallic truss core. Three-points bending experiments were performed to obtain a linear relationship between compliance per span length and the square of the span length for the designed sandwich plate. The specimen was manufactured from the continuous multi-points resistance welding of SUS 3O4H sheets and crimped metallic truss cores. The elastic and shear moduli of the core were estimated by the slopes and the intercepts of the linear relationship, respectively. Through the comparison of the shear moduli and force-deflection considering the core stiffness with those disregarding the core stiffness, it was shown that the core stiffness should be considered to estimate accurately the elastic and shear moduli of a core as well as the force-deflection curves of a thin sandwich plate with a metallic truss core. The contribution ratios of the bending and shear deflections of the thin sandwich plate to the total deflection were investigated. In addition, the influence of the crimping angle on the elastic properties, the force-deflection curves, and the contribution ratios of both bending and shear deflections to the total deflection was examined.

Similar content being viewed by others

Abbreviations

- Π:

-

flexural rigidity of the sandwich plate

- Π1 :

-

local stiffness of the face sheet

- Π2 :

-

bending stiffness of the face sheet

- Π3 :

-

bending stiffness of the core

- tf :

-

thickness of the face sheet

- S:

-

span length in three-points bending test

- b:

-

width of the sandwich plate

- α:

-

thickness of core

- β:

-

distance between neutral axes of face sheets

- γ:

-

thickness of sandwich plate

- ϖf :

-

elastic modulus of face sheets

- ϖc :

-

elastic modulus of the core

- F:

-

measured force in three-points bending test

- δb,max :

-

maximum deflection of the sandwich beam induced by bending moment

- δs,max :

-

maximum deflection of the sandwich beam induced by shear load

- Ωc :

-

shear modulus of the core

- δ:

-

deflection in the center of the sandwich beam

- ηs :

-

compliance per span length

- κa :

-

slope of linear relationship between the compliance per span length and the square of span length

- κb :

-

intercept of linear relationship between the compliance per span length and the square of span length

- ξ:

-

length of struts of unit rhombic mesh

- ts :

-

thickness of struts of unit rhombic mesh

- ϕa :

-

acute angle of unit rhombic mesh

- ϕc :

-

crimping angle of the truss core

- n1 :

-

the number of truss structures per unit length in the width direction

- n2 :

-

the number of truss structures per unit length in the length direction

- k:

-

elastic stiffness of a sandwich beam

- η:

-

compliance of a sandwich beam

- ηs :

-

compliance per span length of a sandwich beam

References

Wadley, H. N. G., Fleck, N. A. and Evans, A. G., “Fabrication and Structural Performance of Periodic Cellular Metal Sandwich Structures,” Composite Science and Technology, Vol. 63, No. 16, pp. 2331–2343, 2003.

Liu, J. S. and Lu, T. J., “Multi-objective and Multi-loading Optimization of Ultralightweight Truss Materials,” International Journal of Solid and Structures, Vol. 41, No. 3–4, pp. 2331–2343, 2003.

Kim, K. J., Sung, C. W., Baik, Y. N., Lee, Y. H., Bae, D. S., Kim, K. H. and Won, S. T., “Hydroforming Simulation of High-strength Steel Cross-members in an Automotive Rear Subframe,” IJPEM, Vol. 9, No. 3, pp. 55–58, 2008.

Kim, K. J., Rhee, M. H., Choi, B. I., Kim, C. W., Sung, C. W., Han, C. P., Kang, K. W. and Won, S. T., “Development of Application Technique of Aluminum Sandwich Sheets for Automotive Hood,” IJPEM, Vol. 10, No. 4, pp. 71–75, 2009.

Wicks, N. and Hutchinson, J. W., “Optimal Truss Plates,” International Journal of Solid and Structures, Vol. 38, No. 30–31, pp. 5165–5183, 2001.

Allen, H. G., “Analysis and Design of Structural Sandwich Panels,” Pergamon Press, 1969.

Styles, M., Compston, P. and Kalyanasundaram, S., “The Effect of Core Thickness on the Flexural Behaviour of Aluminium Foam Sandwich Structures,” Composite Structures, Vol. 80, No. 4, pp. 523–538, 2007.

Hazizan, Md. A. and Cantwell, W. J., “The Low Velocity Impact Response of Foam-based Sandwich Structures,” Composite. Part B, Engineering, Vol. 33, No. 3, pp. 193–204, 2002.

Kang, K. J., Jeon, G. P., Nah, S. J., Ju, B. S. and Hong, N. H., “A New Way to Manufacture Ultra Light Metal Structures,” Transactions of the Korean Society of Mechanical Engineers A, Vol. 28, No. 3, pp. 296–303, 2004.

Hazizan, Md. A. and Cantwell, W. J., “The Low Velocity Impact Response of an Aluminium Honeycomb Sandwich Structures,” Composite. Part B, Engineering, Vol. 34, No. 8, pp. 679–687, 2003.

Jung, C. G., Seoung, D. Y., Yang, D. Y., Moon, K. J. and Ahn, D. G., “Experimental Investigation of Shear Modulus of a Core in a Metallic Sandwich Plate with a Truss Core,” Journal of the KSPE, Vol. 24, No. 8, pp. 67–73, 2007.

Ahn, D. G., Lee, S. H., Jung, C. G., Hahn, G. Y. and Yang, D. Y., “Mechanical Properties and Failure Characteristics of ISB Panel with Metallic Pyramidal Inner Structures,” Journal of Materials Processing Technology, Vol. 187–188, pp. 521–525, 2007.

Ahn, D. G., Moon, G. J., Jung, C. G. and Yang, D. Y., “Variation of Impact Characteristics of ISB Panels with a Pyramidal Inner Structure According to Joining Technologies,” Journal of the KSPE, Vol. 24, No. 9, pp. 110–118, 2007.

Jung, C. G., Seong, D. Y., Yang, D. Y., Na, S. J. and Ahn, D. G., “Development of a Continuous Fabrication System for an Metallic Sandwich Plate with a Three-dimensional Truss Core,” International Journal of Advanced Manufacturing Technology, Vol. 45, No. 3–4, pp. 352–361, 2009.

KS D361, “Expanded Metal,” 1993.

ASTM E270, “Standard Test Method for Semi-guided Bend Test for Ductility of Metallic Materials,” 1995.

Gibson, L. J. and Ashby, M. F., “Cellular Solids: Structure and Properties,” Cambridge University Press, pp. 345–386, 2001.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ahn, DG., Nam, GH., Jung, CG. et al. Experimental determination of elastic properties of the core in a thin sandwich plate with a metallic truss core. Int. J. Precis. Eng. Manuf. 10, 107–113 (2009). https://doi.org/10.1007/s12541-009-0101-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12541-009-0101-5