Abstract

Monel K500 is a high strength, precipitation hardenable, nickel-copper alloy with additions of Al and Ti, having excellent corrosion resistance and ignition resistance to high pressure gaseous oxygen. However, this alloy is highly sensitive to hot workability and is crack prone during hot deformation. This study investigates the effect of hot workability parameters such as temperature, strain rate, and overall strain on the microstructure evolution. The hot deformability of this alloy was studied using isothermal hot compression tests in the temperature range of 850 °C to 1150 °C and at strain rates ranging from 10− 3 to 10 s− 1, using a Gleeble 3800 thermo-mechanical simulator. The flow behaviour was analysed using stress-strain and strain hardening plots. Initial microstructure of the material has as-cast dendritic structure, while microstructural analysis of hot deformed samples revealed gradual reconstitution with increasing temperature and decreasing strain rate. Hot deformed samples showed traces of recrystallized grains and carbides across the matrix at high temperatures and low strain rates. EBSD GROD mapping further elucidates the variation of microstructural features with variation of strain rate. In accordance with the Ziegler instability criterion, processing maps were constructed for a true strain of 0.65, encompassing deformation temperatures between 850 °C and 1150 °C, and strain rates ranging from 0.001 to 10 s− 1. Through an examination of strain rate sensitivity map, processing map and analysis of deformation activation energy, both undesirable (unstable) and potentially favourable (stable) hot deformation parameters were identified. Instability regions in the processing maps were validated with the microstructural features of deformed samples of cast Monel K500 alloy.

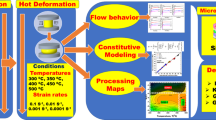

Graphical Abstract

Similar content being viewed by others

Data Availability

The raw/processed data required to reproduce these findings cannot be shared at this time as the data also forms part of an ongoing study.

References

A.R. Kannan, S.M. Kumar, R. Pramod, N.S. Shanmugam, M. Vishnukumar, S.G. Channabasavanna, Mater. Lett. 308, 131262 (2022). https://doi.org/10.1016/j.matlet.2021.131262

K. Sahithya, I. Balasundar, P. Pant, T. Raghu, H.K. Nandi, V. Singh, P. Ghosal, M. Ramakrishna, Mater. Sci. Eng. A 754, 521 (2019). https://doi.org/10.1016/j.msea.2019.03.083

A.G. Kostryzhev, O.O. Marenych, Z. Pan, H. Li, S. van Duin, J. Mater. Sci. 58, 4150 (2023). https://doi.org/10.1007/s10853-023-08248-2

N.S. Stoloff, in Microstructure and Properties of Materials, vol. 1, ed by J.C.M. Li (World Scientific, Singapore, 1996), p. 51. https://doi.org/10.1142/9789814261326_0002

X.P. Zhang, W.Z. Chen, Adv. Mater. Res. 712–715, 87 (2013). https://doi.org/10.4028/www.scientific.net/AMR.712-715.87

A.A. Ganeev, V.A. Valitov, F.Z. Utyashev, V.M. Imaev, Phys. Met. Metallogr. 120, 410 (2019). https://doi.org/10.1134/S0031918X19040057

J.P. Chubb, J. Billingham, Met. Technol. 5, 100 (1978). https://doi.org/10.1179/mt.1978.5.1.100

P. Liu, R. Zhang, Y. Yuan, C. Cui, Y. Zhou, X. Sun, J. Alloys Compd. 831, 154618 (2020). https://doi.org/10.1016/j.jallcom.2020.154618

K. Sahithya, I. Balasundar, P. Pant, T. Raghu, J. Alloys Compd. 821, 153455 (2020). https://doi.org/10.1016/j.jallcom.2019.153455

S.V.S. Narayana Murty, B. Nageswara Rao, B.P. Kashyap, Int. Mater. Rev. 45, 15 (2000). https://doi.org/10.1179/095066000771048782

S.V.S. Narayana Murty, M.S. Sarma, B.N. Rao, Metall. Mater. Trans. A 28, 1581 (1997). https://doi.org/10.1007/s11661-997-0219-y

K.P. Rao, Y.V.R.K. Prasad, in Comprehensive Materials Processing, ed. by S. Hashmi, G.F. Batalha, C.J. Van Tyne, B. Yilbas (Elsevier, Amsterdam, 2014), pp. 397–426. https://doi.org/10.1016/B978-0-08-096532-1.00321-6

Y.V.R.K. Prasad, K.P. Rao, S. Sasidhara (eds.), Hot Working Guide A Compedium of Processing Maps, 2nd edn. (ASM International, Materials Park, 2015), p. 1

H. Ziegler, J. Appl. Math. Mech. 45, 271 (1965). https://doi.org/10.1002/zamm.19650450443

A.P. Mouritz (ed.), in Introduction to Aerospace Materials (Woodhead Publishing, Cambridge, 2012), pp. 57–90. https://doi.org/10.1533/9780857095152.57

C.R. Anoop, R.K. Singh, R.R. Kumar, J. Miyala, S.V.S.N. Murty, K.T. Tharian, Mater. Perform. Charact. 9, 150 (2020). https://doi.org/10.1520/MPC20190081

E.N. Borodin, A.A. Gruzdkov, A.E. Mayer, N.S. Selyutina, J. Phys. Conf. Ser. 991, 012012 (2018). https://doi.org/10.1088/1742-6596/991/1/012012

T. Sakai, J.J. Jonas, Acta Metall. 32, 189 (1984). https://doi.org/10.1016/0001-6160(84)90049-X

G.R. Ebrahimi, A. Momeni, S.M. Abbasi, H. Monajatizadeh, Met. Mater. Int. 19, 11 (2013). https://doi.org/10.1007/s12540-013-1003-8

N.T.B.N. Koundinya, A.K. Karnati, A. Sahadevan, S.V.S.N. Murty, R.S. Kottada, J. Alloys Compd. 930, 167412 (2023). https://doi.org/10.1016/j.jallcom.2022.167412

J. Zhang, C. Wu, Y. Peng, X. Xia, J. Li, J. Ding, C. Liu, X. Chen, J. Dong, Y. Liu, J. Alloys Compd. 835, 155195 (2020). https://doi.org/10.1016/j.jallcom.2020.155195

H. Yuan, W.C. Liu, Mater. Sci. Eng. A 408, 281 (2005). https://doi.org/10.1016/j.msea.2005.08.126

Z. Jia, X. Sun, J. Ji, Y. Wang, B. Wei, L. Yu, Adv. Eng. Mater. 23, 2001048 (2021). https://doi.org/10.1002/adem.202001048

K. Tang, Z. Zhang, J. Tian, Y. Wu, F. Jiang, J. Alloys Compd. 860, 158541 (2021). https://doi.org/10.1016/j.jallcom.2020.158541

S.A. Sajadi, M.R. Toroghinejad, A. Rezaeian, G.R. Ebrahimi, J. Alloys Compd. 896, 162732 (2022). https://doi.org/10.1016/j.jallcom.2021.162732

J. Luan, C. Sun, X. Li, Q. Zhang, Mater. Sci. Technol. 30, 211 (2014). https://doi.org/10.1179/1743284713Y.0000000341

P. Wanjara, M. Jahazi, H. Monajati, S. Yue, J.-P. Immarigeon, Mater. Sci. Eng. A 396, 50 (2005). https://doi.org/10.1016/j.msea.2004.12.005

I.N. Ganiev, F.S. Zokirov, M.M. Sangov, N.F. Ibrokhimov, High. Temp. 56, 867 (2018). https://doi.org/10.1134/S0018151X18060093

P. Wan, H. Zou, K. Wang, Z. Zhao, S. Lu, H. Nie, Metals. 10, 956 (2020). https://doi.org/10.3390/met10070956

I. Balasundar, K.R. Ravi, T. Raghu, Mater. Sci. Eng. A 684, 135 (2017). https://doi.org/10.1016/j.msea.2016.12.043

N. Neethu, P. Chakravarthy, Metall. Mater. Trans. A 51, 3398 (2020). https://doi.org/10.1007/s11661-020-05817-x

Y.V.R.K. Prasad, T. Seshacharyulu, Int. Mater. Rev. 43, 243 (1998). https://doi.org/10.1179/imr.1998.43.6.243

S.V.S. Narayana Murty, B. Nageswara Rao, B.P. Kashyap, J. Mater. Process. Technol. 166, 268 (2005). https://doi.org/10.1016/j.jmatprotec.2004.09.089

H.J. McQueen, N.D. Ryan, Mater. Sci. Eng. A 322, 43 (2002). https://doi.org/10.1016/S0921-5093(01)01117-0

Y. Liu, R. Hu, J. Li, H. Kou, H. Li, H. Chang, H. Fu, Mater. Sci. Eng. A 508, 141 (2009). https://doi.org/10.1016/j.msea.2008.12.032

A.K. Godasu, U. Prakash, S. Mula, J. Alloys Compd. 844, 156200 (2020). https://doi.org/10.1016/j.jallcom.2020.156200

H. Zhou, H. Zhang, J. Liu, S. Qin, Y. Lv, Rare Met. Mater. Eng. 47, 3329 (2018). https://doi.org/10.1016/s1875-5372(18)30240-6

C.M. Sellars, W.J. McTegart, Acta Metall. 14, 1136 (1966). https://doi.org/10.1016/0001-6160(66)90207-0

Y. Lee, M. Nordin, S.S. Babu, D.F. Farson, Metall. Mater. Trans. B 45, 1520 (2014). https://doi.org/10.1007/s11663-014-0054-7

J. Obiko, IOP SciNotes. 2, 014401 (2021) https://doi.org/10.1088/2633-1357/abdd96

Y.V.R.K. Prasad, S. Sasidhara, V.K. Sikka, Intermetallics. 8, 987 (2000). https://doi.org/10.1016/S0966-9795(00)00048-0

Y. Li, Y. Guan, H. Chen, J. Zhai, J. Lin, L. Chen, Met. Mater. Int. 27, 4195 (2021). https://doi.org/10.1007/s12540-020-00857-9

S. Tabaie, D. Shahriari, C. Plouze, A. Devaux, J. Cormier, M. Jahazi, Mater. Sci. Eng. A 766, 138391 (2019). https://doi.org/10.1016/j.msea.2019.138391

M.J. Weis, M.C. Mataya, S.W. Thompson, D.K. Matlock, in Superalloy 718: Metallurgy and Applications: Proceedings of the International Symposium on the Metallurgy and Applications of Superalloy 718, ed. by E.A. Loria (TMS, Pittsburgh, 1989), p. 135. https://doi.org/10.7449/1989/superalloys_1989_135_154

S.S.S. Kumar, T. Raghu, P.P. Bhattacharjee, G.A. Rao, U. Borah, J. Alloys Compd. 709, 394 (2017). https://doi.org/10.1016/j.jallcom.2017.03.158

H. Xu, Y. Li, H. Li, J. Wang, G. Liu, Y. Song, Metals. 12, 1496 (2022). https://doi.org/10.3390/met12091496

A. Najafizadeh, J.J. Jonas, ISIJ Int. 46, 1679 (2006). https://doi.org/10.2355/isijinternational.46.1679

M. Al-Saadi, C. Hulme-Smith, F. Sandberg, P.G. Jönsson, J. Mater. Eng. Perform. 30, 7770 (2021). https://doi.org/10.1007/s11665-021-05957-0

P. Neelima, S.V.S. Narayana Murty, P. Chakravarthy, Mater. Perform. Charact. 9, 237 (2020). https://doi.org/10.1520/MPC20190045

N.R. Jaladurgam, A.K. Kanjarla, Mater. Sci. Eng. A 712, 240 (2018). https://doi.org/10.1016/j.msea.2017.11.056

D.V. Vaganov, S. Zhevnenko, Defect Diffus. Forum. 249, 115 (2006). https://doi.org/10.4028/www.scientific.net/ddf.249.115

M.C. Flemings, Solidification processing. Metall. Trans. 5, 2121 (1974). https://doi.org/10.1007/BF02643923

T.R. Bieler, S.C. Sutton, B.E. Dunlap, Z.A. Keith, P. Eisenlohr, M.A. Crimp, B.L. Boyce, JOM. 66, 121 (2014). https://doi.org/10.1007/s11837-013-0821-y

L. Despax, V. Vidal, D. Delagnes, M. Dehmas, H. Matsumoto, V. Velay, Mater. Sci. Eng. A 790, 139718 (2020). https://doi.org/10.1016/j.msea.2020.139718

Acknowledgements

The authors are grateful to Director, LPSC for granting permission to publish this work. Support of M/s MIDHANI, Hyderabad is highly appreciated towards realisation and supply of this material.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Funding.

This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors.

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Dey, S., Kumar, R.R., Florist, V. et al. Hot Workability and Microstructure Control in Monel K 500 in as Cast Condition: An Approach Using Pressing Maps. Met. Mater. Int. (2024). https://doi.org/10.1007/s12540-024-01693-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12540-024-01693-x