Abstract

This study focuses on the effect of a plasma nitriding (PN) process on the thermal stability of nanocrystalline on the surface of Ti-6Al-4 V (Ti64) titanium alloy, which is printed by selective laser melting (SLM) and subsequently treated by laser shock peening (LSP). The microstructure evolution of SLM-Ti64 titanium alloy treated sequentially by LSP and PN at different annealing temperatures was observed by X-ray diffraction, differential scanning calorimeter, scanning electron microscope, and transmission electron microscope. The results show that the average size of SLM-Ti64 alloy treated by LSP is 49.7 nm, even at 600 °C nanocrystals maintain thermal stability, which is attributed to the strong hinder effect of high-density dislocations on grain boundary migration. The microstructural characterization indicates that the nitrided layer is mainly composed of nanostructured TiN phase by PN at 600 °C, and the thermal stability of nanocrystals was further increased to 700 °C compared without nitriding, which is attributed to dispersed nanoscale TiN precipitates hindering the migration of grain boundaries by Zener pinning effect. Our work provides a method of preventing nanocrystalline coarsening in Ti64 alloy by PN.

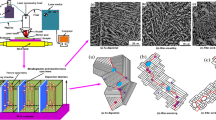

Graphical Abstract

Similar content being viewed by others

References

T. DebRoy, T. Mukherjee, H.L. Wei, J.W. Elmer, J.O. Milewski, Metallurgy, mechanistic models and machine learning in metal printing. Nat. Rev. Mater. 6(1), 48–68 (2021)

D. Zhang, D. Qiu, M.A. Gibson, Y. Zheng, M.A. Easton, Additive manufacturing of ultrafine-grained high-strength titanium alloys. Nature. 576(7785), 91–95 (2019)

M.R. Bandekhoda, M.H. Mosallanejad, M. Atapour, L. Iuliano, A. Saboori, Laser peening: a review of the factors, effects, applications, comparison with Shot Peening and State-of-the-art. Met. Mater. Int. 30, 259–283 (2024)

A.F. Chadwick, P.W. Voorhees, The development of grain structure during additive manufacturing. Acta Mater. 211, 116862 (2021)

C.Y. Bai, L. Lan, R.Y. Xin, S. Gao, B. He, Microstructure evolution and cyclic deformation behavior of Ti-6Al-4 V alloy via electron beam melting during low cycle fatigue. Int. J. Fatigue. 159, 106784 (2022)

T.H. Becker, P. Kumar, U. Ramamurty, Fracture and fatigue in additively manufactured metals. Acta Mater. 219, 117240 (2021)

S. Adu-Gyamfi, X.D. Ren, E.A. Larson, Y. Ren, Z. Tong, The effects of laser shock peening scanning patterns on residual stress distribution and fatigue life of AA2024 aluminium alloy. Opt. Laser Technol. 108, 177–185 (2018)

H. Zhang, Z. Cai, J. Chi, R. Sun, Z. Che, L. Lin, P. Peng, H. Zhang, W. Guo, Gradient microstructure evolution in laser shock peened Ti6Al4V titanium alloy. Surf. Coat. Technol. 437, 128378 (2022)

M. Ayeb, M. Frija, R. Fathallah, Investigation on the potential of laser and Electron Beam Additively Manufactured Ti–6Al–4V components for Orthopedic Applications. Met. Mater. Int. 30, 114–126 (2024)

N. Kalentics, N. Sohrabi, H.G. Tabasi, S. Griffiths, J. Jhabvala, C. Leinenbach, A. Burn, R.E. Loge, Healing cracks in selective laser melting by 3D laser shock peening. Addit. Manuf. 30, 10081 (2019)

S.N. Singh, A.B. Deoghare, Laser shock peening of laser based Directed Energy Deposition and Powder Bed Fusion additively manufactured parts: a review. Met. Mater. Int. 29, 1563–1585 (2023)

N. Kalentics, E. Boillat, P. Peyre, C. Gorny, C. Kenel, C. Leinenbach, J. Jhabvala, Loge, 3D laser shock peening - a new method for the 3D control of residual stresses in selective laser melting. Mater. Des. 130, 350–356 (2017)

N. Kalentics, M.O.V. de Seijas, S. Griffiths, C. Leinenbach, R.E. Loge, 3D laser shock peening - a new method for improving fatigue properties of selective laser melted parts. Addit. Manuf. 33, 101112 (2020)

L. Lan, R.Y. Xin, X.Y. Jin, S. Gao, B. He, Y.H. Rong, N. Min, Effects of Laser Shock Peening on Microstructure and properties of Ti-6Al-4V Titanium Alloy fabricated via selective laser melting. Materials. 13(15), 3261 (2020)

L. Lan, X.Y. Jin, S. Gao, B. He, Y.H. Rong, Microstructural evolution and stress state related to mechanical properties of electron beam melted Ti-6Al-4V alloy modified by laser shock peening. J. Mater. Sci. Technol. 50, 153–161 (2020)

X. Zhou, X.Y. Li, K. Lu, Enhanced thermal stability of nanograined metals below a critical grain size. Science. 360, 526–530 (2018)

X.Y. Li, X. Zhou, K. Lu, Rapid heating induced ultrahigh stability of nanograined copper. Sci. Adv. 6(17), eaaz8003 (2020)

X. Zhou, X.Y. Li, K. Lu, Strain hardening in gradient nano-grained Cu at 77 K. Scr. Mater. 153, 6–9 (2018)

Y.-. Mai, X.-. Jie, L.-. Liu, N. Yu, X.-x. Zheng, Thermal stability of nanocrystalline layers fabricated by surface nanocrystallization. Appl. Surf. Sci. 256(7), 1972–1975 (2010)

Y. Xiao, L. Lan, S. Gao, B. He, Y. Rong, Mechanism of ultrahigh ductility obtained by globularization of αGB for additive manufacturing Ti–6Al–4V. Mater. Sci. Eng. A 858, 144174 (2022)

S. Cao, R. Chu, X. Zhou, K. Yang, Q. Jia, C.V.S. Lim, A. Huang, X. Wu, Role of martensite decomposition in tensile properties of selective laser melted Ti-6Al-4V. J. Alloy. Compd. 744, 357–363 (2018)

C.C. Koch, R.O. Scattergood, M. Saber, H. Kotan, High temperature stabilization of nanocrystalline grain size: thermodynamic versus kinetic strategies. J. Mater. Res. 28(13), 1785–1791 (2013)

Y. Yang, K. Zhou, H. Zhang, H. Hu, H. Qiao, Thermal stability of microstructures induced by laser shock peening in TC17 titanium alloy. J. Alloy. Compd. 767, 253–258 (2018)

L. Chen, X. Ren, W. Zhou, Z. Tong, S. Adu-Gyamfi, Y. Ye, Y. Ren, Evolution of microstructure and grain refinement mechanism of pure nickel induced by laser shock peening. Mater. Sci. Eng. A 728, 20–29 (2018)

Z.B.W. A, N.R.T. A, W.P.T. A, J.L. B, Diffusion of chromium in nanocrystalline iron produced by means of surface mechanical attrition treatment. Acta Mater. 51(14), 4319–4329 (2003)

L. Ge, N. Tian, Z. Lu, C. You, Influence of the surface nanocrystallization on the gas nitriding of Ti–6Al–4V alloy. Appl. Surf. Sci. 286, 412–416 (2013)

A. Wang, J. Wang, F. Yang, T. Wen, H. Yang, S. Ji, Improved strength-ductility synergy of a CoCrNi Medium-Entropy Alloy by Ex situ TiN nanoparticles. Adv. Eng. Mater. 25(2), 2200939 (2023)

X. Zhang, R. Li, L. Huang, A. Amar, C. Wu, G. Le, X. Liu, D. Guan, G. Yang, J. Li, Influence of in-situ and ex-situ precipitations on microstructure and mechanical properties of additive manufacturing CoCrFeMnNi high-entropy alloys. Vacuum. 187, 110111 (2021)

W. Cui, G. Qin, J. Duan, H. Wang, A graded nano-TiN coating on biomedical Ti alloy: Low friction coefficient, good bonding and biocompatibility, Mater. Sci. Eng. C 71, 520–528 (2017)

L. Zhu, J.N. He, D.R. Yan, L.S. Xiao, Y.C. Dong, D.C. Xue, D.L. Meng, Titanium Carbonitride thick coating prepared by plasma spray synthesis and its tribological properties. Chin. Sci. Bull. 52(13), 1849–1855 (2007)

O. Unal, E. Maleki, R. Varol, Effect of severe shot peening and ultra-low temperature plasma nitriding on Ti-6Al-4V alloy. Vacuum. 150, 69–78 (2018)

S.M. Hassani-Gangaraj, A. Moridi, M. Guagliano, A. Ghidini, Nitriding duration reduction without sacrificing mechanical characteristics and fatigue behavior: the beneficial effect of surface nano-crystallization by prior severe shot peening. Mater. Des. 55, 492–498 (2014)

R.Y. Xin, L. Lan, C.Y. Bai, S. Gao, B. He, J. Wang, Fatigue properties of selective laser melted Ti-6Al-4V alloy subjected to laser shock processing. J. Mater. Sci. 57(21), 9619–9630 (2022)

K. Wen, C. Zhang, Y. Gao, Influence of gas pressure on the low-temperature plasma nitriding of surface-nanocrystallined TC4 titanium alloy, surf. Coat. Technol. 436, 128327 (2022)

Q. Yao, J. Sun, G. Zhang, W. Tong, H. Zhang, Enhanced toughness of nitrided layers formed on Ti-6Al-4V alloy via surface mechanical attrition pre-treatment. Vacuum. 142, 45–51 (2017)

A. Zhecheva, W. Sha, S. Malinov, A. Long, Enhancing the microstructure and properties of titanium alloys through nitriding and other surface engineering methods. Surf. Coat. Technol. 200(7), 2192–2207 (2005)

K. Farokhzadeh, A. Edrisy, Fatigue improvement in low temperature plasma nitrided Ti-6Al-4V alloy. Mater. Sci. Eng. A 620, 435–444 (2015)

J. Sun, L.Y. Mei, Y. Li, Y.Y. Lei, X.D. Du, Y.C. Wu, Two-step nitriding behavior of pure Iron with a Nanostructured Surface Layer. Adv. Eng. Mater. 21(10), 1900359 (2019)

H. Ferkel, M. Glatzer, Y. Estrin, R.Z. Valiev, C. Blawert, B.L. Mordike, RF plasma nitriding of severely deformed iron-based alloys. Mater. Sci. Eng. A 348(1–2), 100–110 (2003)

F.W. Tang, X.M. Liu, H.B. Wang, C. Hou, H. Lu, Z.R. Nie, X.Y. Song, Solute segregation and thermal stability of nanocrystalline solid solution systems. Nanoscale. 11(4), 1813–1826 (2019)

U. Herr, Phase Stability in Nanostructures. Adv. Eng. Mater. 3, 889–893 (2001)

X.D. Ren, W.F. Zhou, F.F. Liu, Y.P. Ren, S.Q. Yuan, N.F. Ren, S.D. Xu, T. Yang, Microstructure evolution and grain refinement of Ti-6Al-4V alloy by laser shock processing. Appl. Surf. Sci. 363, 44–49 (2016)

J. Zhang, X. Ou, Thermal stability of nanocrystalline in surface layer of magnesium alloy AZ91D, Trans. Nonferrous Met. Soc. China. 20(7), 1340–1344 (2010)

A. Michels, C.E. Krill, H. Ehrhardt, R. Birringer, D.T. Wu, Modelling the influence of grain-size-dependent solute drag on the kinetics of grain growth in nanocrystalline materials. Acta Mater. 47(7), 2143–2152 (1999)

D.A. Porter, K.E. Easterling, Phase Transformations in Metals and Alloys, 3rd edn. (CRC Press, 1992)

J. Liu, S. Suslov, A. Vellore, Z. Ren, A. Amanov, Y.-S. Pyun, A. Martini, Y. Dong, C. Ye, Surface nanocrystallization by ultrasonic nano-crystal surface modification and its effect on gas nitriding of Ti6Al4V alloy. Mater. Sci. Eng. A 736, 335–343 (2018)

A. Dhal, S.K. Panigrahi, M.S. Shunmugam, Precipitation phenomena, thermal stability and grain growth kinetics in an ultra-fine grained Al 2014 alloy after annealing treatment. J. Alloy. Compd. 649, 229–238 (2015)

Acknowledgements

This work was financially supported by Class III Peak Discipline of Shanghai—Materials Science and Engineering (High-Energy Beam Intelligent Processing and Green Manufacturing). The authors thank Fei Wang for preparing the experimental samples.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wang, J., He, B., Liu, C. et al. Thermal Stability of Nanocrystals in SLM-printed Ti64 Alloy Treated by Laser Shock Peening and Plasma Nitriding. Met. Mater. Int. (2024). https://doi.org/10.1007/s12540-024-01671-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12540-024-01671-3