Abstract

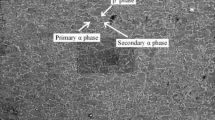

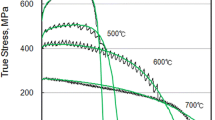

The utilization of Titanium-clad steel plate (TCSP) spans various industries. Over time, there has been an increasing demand for enhanced mechanical properties, leading to the advancement of high-strength TCSP. As a result, self-produced high-strength TCSP was utilized to investigate the cooperative deformation behavior during isothermal axial thermal compression (TC) tests and to establish the constitutive equations and processing map. The results indicated that the TCSP did not deform cooperatively throughout the entire TC process. Initially, the titanium matrix deformed, and only when its strength matched that of the steel matrix did the TCSP deform cooperatively. The microstructure of the steel matrix revealed an increasing number of deformation grains, while the titanium matrix exhibited an increase in substructure grains with temperature. The primary orientation of the steel matrix was (101), while that of the titanium matrix was (01 \(\overline{1 }\) 0) after TC. Furthermore, it was observed that the titanium matrix displayed a distinctive plate texture, while the steel matrix exhibited a mixed texture that became increasingly pronounced with temperature. The constitutive equation was derived using the Arrhenius model, and the material constants were represented by a fourth-order polynomial fit to the true strain. The established constitutive equation exhibited an accuracy of 96.27%. Finally, the process map constructed using the dynamic material model revealed the presence of four distinct zones.

Graphical Abstract

Similar content being viewed by others

References

R. Yang, Acta Metall. Sin. 51, 129 (2015)

I. Weiss, S.L. Semiatin, Mat. Sci. Eng. A 243, 46 (1998)

I. Weiss, S.L. Semiatin, Mater. Sci. Eng. A 263, 243 (1999)

J.-P. Gourmelon, Res. Technol. 100, 1093 (2003)

K. Lundgren, Mag. Concr. Res. 59, 447 (2007)

Q. Zhou, R. Liu, Q. Zhou, C. Ran, K. Fan, J. Xie, P Chen, Mat. Sci. Eng. A 830, 142260 (2022)

T.N. Prasanthi, C. Sudha Ravikirana, S. Saroja, Mater. Des. 93, 180 (2016)

X. Yang, C. Shi, Y. Ge, M. Sabuj, J. Iron. Steel Res. Int. 25, 347 (2018)

R.S. Revuru, N.R. Posinasetti, Venkata Ramana V.S.N., Amrita M., Int. J. Adv. Manuf. Tech. 91, 2477 (2017)

X. Chen. H. Xiao, Y. Shi, C. Qian, Q. Zhang, P. Shao, Z. Yang, Z. Huang, K. Liu, Vacuum 214, 112158 (2023)

N. Kahraman, B. Gülen, F. Findik, J. Mater. Process. Tech. 169, 127 (2005)

Z. Luo, G. Wang, G. Xie, L. Wang, K. Zhao, Acta Metall. Sin. (Engl. Lett.) 26, 754 (2013)

C. Velmurugan, V. Senthilkumar, S. Sarala, J. Arivarasan, J. Mater. Process. Tech. 234, 272 (2016)

X. Li, Z. Bi, Q. Wang, Q. Wang, K. Rong, M. Xu, T. Zhang, J. Qian, Mater. Today Com. 34, 105143 (2023)

J. Sun, X. Liang, S. Jiao, Baosteel Tech. Res. 11, 32 (2017)

Y. Bai, X. Liu, W. Wang, Y. Yang, Chin. J. Eng. 43, 85 (2021)

Q. Shi, W. Wu, M. Zhang, Ordnance Mater. Sci. Eng. 42, 1 (2019)

C. Shi, X. Yang, H. Shi, Z. Fang, Z. Sun, K. Feng, F. Shao, Russ. J. Non-Ferrous Met. 60, 152 (2019)

C. Yu , L. Fu , H. Xiao ,Q. Lv, B. Gao, Mater. Sci. Eng. A 820, 141572 (2021)

S. Tian, H. Jiang, J. Liu, G. Zhang, Z. Xu, Mater. Rep. 33, 4141 (2019)

S.-W. Zeng, A.-M. Zhao, H.-T. Jiang, X.-Q. Yan, J.-X. Liu, X.-G. Duan, Rare Met. 34, 764 (2015)

J. Cheng, B. Zhang, Z. Zhang, T. Zhao, P. Liu, F. Zhao, J. Plas. Engi. 28, 132 (2021)

H. Jiang, X. Yan, J. Liu, X. Duan, T. Nonferr. Metal. Soc. 24, 697 (2014)

H. Jiang, X. Yan, J. Liu, X. Duan, S. Zeng, Rare Metal Mat. Eng. 43, 2631 (2014)

H. Bu, Q. Li, S. Li, M. Li, Metals 12, 1270 (2022)

N.P. Gurao, R. Kapoor, S. Suwas, Acta Mater. 59, 3431 (2011)

Z. Liu, S. Chen, M. Zhou, X. Liu, G. Wang, J. Iron Steel Res. 16, 49 (2004)

W. Huang, Y. Wang, Z. Li, Y. Xia, Chi. J. Nonferr. Met. 18, 1440 (2008)

H. Zhang, J. Yi, J. Wang, H. Xiao, M. Wang, W. Wang, Metals 12, 2018 (2022)

S. Zhang, G. Song, Y. Xu, H. Song, M. Cheng, J. Netshape Form. Eng. 6, 1 (2014)

C. Yang, J.A. Lin, Y.F. Ding, W.W. Zhang, Y.Y. Li, Z.Q. Fu, E.J. Levernia, J. Mater. Sci. 51, 10608 (2016)

Z. Shi, X. Yan, C. Duan, J. Alloys Compd. 652, 30 (2015)

T. Sato, Y. Kwon, Y. Matsumiya, H. Watanabe, Phys. Flu. 33, 063106 (2021)

A.H. Sheikhali, M. Morakkabati, S.M. Abbasi, J. Mater. Eng. Perform. 28, 6525 (2019)

X. Yang, H. Guo, H. Liang, Z. Yao, S. Yuan, J. Mater. Eng. Perform. 25, 1347 (2016)

T.G. Langdon, Mater. Sci. Eng. A 283, 266 (2000)

R. Mahmudi, A. Rezaee-Bazzaz, H. Banaie-Fard, J. Alloys Compd. 429, 192 (2007)

Y.V.R.K. Prasad, H.L. Gegel, S.M. Doraivelu, J.C. Malas, J.T. Morgan, K.A. Lark, D.R. Barker, Metall. Trans. A 15, 1883 (1984)

G.Z. Quan, Y. Wang, C.T. Yu, J. Zhou, Mater. Sci. Eng. A 564, 46 (2013)

Y.V.R.K. Prasad, T. Seshacharyulu, Mater. Sci. Eng. A 243, 82 (1998)

D. Zhou, W. Zeng, J. Xu, W. Chen, S. Wang, Adv. Eng. Mater. 21, 1801232 (2019)

Acknowledgements

The work is supported by the Yunnan Provincial Major Science and Technology Special Plan of China (No. 202002AB080016).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Chen, X., Xiao, H., Shao, P. et al. Cooperative Deformation Behavior and Microstructure Evolution of High-Strength Titanium-Clad Steel Plate During Thermal Compression. Met. Mater. Int. (2024). https://doi.org/10.1007/s12540-024-01652-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12540-024-01652-6