Abstract

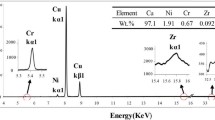

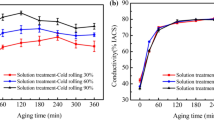

Continuous extrusion is a very promising technique for forming Cu–Cr–Zr alloys which takes the upward continuous casted rods as raw materials. While the hot deformation behavior and constitutive equation of as-cast rods have never been reported. In the present study, the hot deformation behavior of as-cast Cu–Cr–Zr rods with columnar grains was investigated. The results showed that the flow stress at 500 °C is higher than that at 400 °C. The reason for that can be attributed to the dynamic precipitation process, which was confirmed by TEM observations. At this temperature, partial CDRX dominates the softening mechanism while at high temperatures DRV and DDRX play a critical role. The constitutive equation was then established and the deformation activation energy was determined to be 541.93 kJ/mol. The high activation energy was attributed to the large solidified columnar grains. At high strains, stable metal flows can be obtained at high strain rates and high temperatures according to the processing maps, which indicates that a high-speed deformation at a high temperature is favorable to the plastic forming of this material. This investigation thus provides valuable information on how to process the Cu–Cr–Zr rods by plastic deformation methods, for example, continuous extrusion.

Graphical Abstract

Similar content being viewed by others

References

H. Fu, S. Xu, W. Li, J. Xie, H. Zhao, Z. Pan, Mater. Sci. Eng. A 700, 107 (2017). https://doi.org/10.1016/j.msea.2017.05.114

A.H. Huang, Y.F. Wang, M.S. Wang, L.Y. Song, Y.S. Li, L. Gao, C.X. Huang, Y.T. Zhu, Mater. Sci. Eng. A 746, 211 (2019). https://doi.org/10.1016/j.msea.2019.01.002

S. Ma, Q. Zhang, J. Fan, L. Fu, M. Wen, M. Liu, A. Shan, Mater. Sci. Eng. A 885, 145614 (2023). https://doi.org/10.1016/j.msea.2023.145614

H. Fu, Y. Yin, Y. Zhang, M. Zhang, X. Yun, Mater. Des. 222, 111033 (2022). https://doi.org/10.1016/j.matdes.2022.111033

H. Fu, Y. Zhang, M. Zhang, X. Yun, J. Mater. Process. Technol. 317, 117986 (2023). https://doi.org/10.1016/j.jmatprotec.2023.117986

Y. Zhang, X. Yun, R. Zhao, F. Zhu, H. Fu, J. Mater. Res. Technol. 27, 3860 (2023). https://doi.org/10.1016/j.jmrt.2023.10.305

M. Zhou, X. Yun, H. Fu, J. Manuf. Process. 82, 559 (2022). https://doi.org/10.1016/j.jmapro.2022.08.037

Z. Shen, Z. Lin, P. Shi, G. Tang, T. Zheng, C. Liu, Y. Guo, Y. Zhong, Mater. Sci. Eng. A 820, 141548 (2021). https://doi.org/10.1016/j.msea.2021.141548

Z. Ding, S. Jia, P. Zhao, M. Deng, K. Song, Mater. Sci. Eng. A 570, 87 (2013). https://doi.org/10.1016/j.msea.2013.01.059

A. Sarkar, M.J.N.V. Prasad, S.V.S.N. Murty, Mater. Charact. 160, 110112 (2020). https://doi.org/10.1016/j.matchar.2019.110112

Y. Zhang, Z. Chai, A.A. Volinsky, H. Sun, B. Tian, P. Liu, Y. Liu, J. Mater. Eng. Perform. 25, 1191 (2016). https://doi.org/10.1007/s11665-016-1937-3

Y. Zhang, S. Huili, A.A. Volinsky, B. Tian, Z. Chai, P. Liu, Y. Liu, J. Mater. Eng. Perform. 25, 1150 (2016). https://doi.org/10.1007/s11665-016-1914-x

Y. Cai, C. Tian, S. Fu, G. Han, C. Cui, Q. Zhang, Mater. Sci. Eng. A 638, 314 (2015). https://doi.org/10.1016/j.msea.2015.04.033

B.K. Choudhary, Mater. Sci. Eng. A 564, 303 (2013). https://doi.org/10.1016/j.msea.2012.11.104

L. Yuan, X. Gao, X. Zhang, Y.A. Yang, Mater. Sci. Eng. A 680, 115 (2017). https://doi.org/10.1016/j.msea.2016.10.086

Z. Li, L. Zhang, N. Sun, L. Fu, A. Shan, Mater. Lett. 150, 108 (2015). https://doi.org/10.1016/j.matlet.2015.03.007

K.S. Chandravathi, K. Laha, P. Parameswaran, M.D. Mathew, Int. J. Pres. Vessels Pip. 89, 162 (2012). https://doi.org/10.1016/j.ijpvp.2011.10.021

Y.C. Lin, H. Yang, Y. Xin, C.-Z. Li, Mater. Charact. 144, 9 (2018). https://doi.org/10.1016/j.matchar.2018.06.029

C.M. Sellars, W.J. McTegart, Acta Metall. 14, 1136 (1966). https://doi.org/10.1016/0001-6160(66)90207-0

Y. Ban, Y. Zhang, Y. Jia, B. Tian, A.A. Volinsky, X. Zhang, Q. Zhang, Y. Geng, Y. Liu, X. Li, Mater. Des. 191, 108613 (2020). https://doi.org/10.1016/j.matdes.2020.108613

Y. Geng, X. Li, H. Zhou, Y. Zhang, Y. Jia, B. Tian, Y. Liu, A.A. Volinsky, X. Zhang, K. Song, G. Wang, L. Li, J. Hou, J. Alloys Compd. 821, 153518 (2020). https://doi.org/10.1016/j.jallcom.2019.153518

Y. Geng, Y. Zhang, K. Song, Y. Jia, X. Li, H.-R. Stock, H. Zhou, B. Tian, Y. Liu, A.A. Volinsky, X. Zhang, P. Liu, X. Chen, J. Alloys Compd. 842, 155666 (2020). https://doi.org/10.1016/j.jallcom.2020.155666

A.K. Godasu, U. Prakash, S. Mula, J. Alloys Compd. 844, 156200 (2020). https://doi.org/10.1016/j.jallcom.2020.156200

H. Fu, J. Li, X. Yun, Mater. Sci. Eng. A 824, 141862 (2021). https://doi.org/10.1016/j.msea.2021.141862

J.Y. Shen, L.X. Hu, Y. Sun, X.Y. Feng, A.W. Fang, Z.P. Wan, J. Alloys Compd. 822, 153735 (2020). https://doi.org/10.1016/j.jallcom.2020.153735

Y. Wang, J. Wang, J. Dong, A. Li, Z. Li, G. Xie, L. Lou, J. Mater. Sci. Technol. 34, 2439 (2018). https://doi.org/10.1016/j.jmst.2018.04.001

X. Chen, Q. Liao, Y. Niu, Y. Jia, Q. Le, S. Ning, C. Hu, K. Hu, F. Yu, J. Alloys Compd. 803, 585 (2019). https://doi.org/10.1016/j.jallcom.2019.06.242

Q. Zhao, F. Yang, R. Torrens, L. Bolzoni, Mater. Des. 169, 107682 (2019). https://doi.org/10.1016/j.matdes.2019.107682

G. Ji, Q. Li, K. Ding, L. Yang, L. Li, J. Alloys Compd. 648, 397 (2015). https://doi.org/10.1016/j.jallcom.2015.06.264

Y. Zhang, H.-L. Sun, A.A. Volinsky, B.-H. Tian, Z. Chai, P. Liu, Y. Liu, Acta Metall. Sin.-Engl. 29, 422 (2016). https://doi.org/10.1007/s40195-016-0404-3

Y. Zhang, J. Guo, J. Chen, C. Wu, K.S. Kormout, P. Ghosh, Z. Zhang, J. Alloys Compd. 776, 807 (2019). https://doi.org/10.1016/j.jallcom.2018.10.275

Acknowledgements

This work is supported by the National Natural Science Foundation of China (No. 52275312), the Science and Technology Planning Project of Liaoning Province (No. 2023JH2/101300241), the Educational Department of Liaoning Province (Nos. LJKMZ20220867, LJKMZ20222211, and LJKFZ20220202).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhang, Y., Yun, X., Zhu, F. et al. Hot Deformation Behavior and Constitutive Equation of Cu–Cr–Zr Rods Prepared by Upward Continuous Casting. Met. Mater. Int. (2024). https://doi.org/10.1007/s12540-024-01651-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12540-024-01651-7