Abstract

This study investigated the effects of solution heat treatment and multi-directional forging (MDF) on the microstructure, mechanical, and corrosion properties of an Mg–2Zn–0.2Ag alloy. Microstructural characterization by field emission scanning electron microscopy indicated that the as-cast material consists of some MgZn2 and Ag-rich MgZn precipitates. These silver-rich MgZn precipitates were entirely and partially dissolved after the solution treatment and MDF, respectively. In addition, the grain size of the as-cast alloy increased by 86% and decreased by 43% after solution heat treatment and MDF, respectively. The ultimate shear strength of the as-cast material increased by 25% and reached 149.5 MPa after MDF processing, while it did not change significantly after solution treatment. The obtained results indicated that the corrosion layer formed on the samples consists of an inner layer (magnesium hydroxide) and an outer layer (phosphate compounds). Based on the corrosion tests, it was found that solution heat treatment and MDF could significantly improve the corrosion resistance of the as-cast Mg–2Zn–0.2Ag. The corrosion resistance (Rp) obtained from the electrochemical impedance spectroscopy (EIS) test exhibited enhancements of 119% and 152% after heat treatment and MDF processes, respectively. This improvement in corrosion resistance was attributed to the higher stability of the outer layer in both solution-treated and MDF-processed samples, compared to the as-cast material. The results of cell studies also indicated a significant improvement in the cell viability of the solution-treated Mg–2Zn–0.2Ag alloy sample compared with pure Mg.

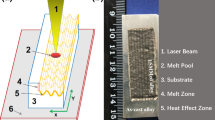

Graphical Abstract

Similar content being viewed by others

Data availability

The raw/processed data required to reproduce these findings cannot be shared at this time due to technical or time limitations.

References

N. Hassanzadeh, T.G. Langdon, J. Mater. Sci.ci. 58, 13721 (2023). https://doi.org/10.1007/s10853-023-08828-2

Y. Luo, C. Zhang, J. Wang, F. Liu, K.W. Chau, L. Qin, J. Wang, Bioact. Mater. 6, 3231 (2021). https://doi.org/10.1016/j.bioactmat.2021.02.032

J. Wang, Y. Wu, H. Li, Y. Liu, X. Bai, W. Chau, Y. Zheng, L. Qin, Biomaterials 157, 86 (2018). https://doi.org/10.1016/j.biomaterials.2017.12.007

K. Bryła, J. Horky, M. Krystian, L. Lityńska-Dobrzyńska, B. Mingler, Mater. Sci. Eng. C 109, 110543 (2020). https://doi.org/10.1016/j.msec.2019.110543

U. Krishnaveni, S. Kumaran, Met. Mater. Int. 29, 2093 (2023). https://doi.org/10.1007/s12540-022-01362-x

M. Johari, S.H. Tabaian, S. Saeedi, Met. Mater. Int. 28, 1386 (2022). https://doi.org/10.1007/s12540-021-01010-w

J. Song, J. She, D. Chen, F. Pan, J. Magnes. Alloy. 8, 1 (2020). https://doi.org/10.1016/j.jma.2020.02.003

M. Jamalpour, R. Alizadeh, Intermetallics 165, 108133 (2024). https://doi.org/10.1016/j.intermet.2023.108133

M. Jamalpour, R. Alizadeh, Mater. Sci. Eng. A 859, 144209 (2022). https://doi.org/10.1016/j.msea.2022.144209

M. Asadollahi, R. Alizadeh, S.K. Sadrnezhaad, J. Mater. Res. Technol. 26, 1553 (2023). https://doi.org/10.1016/j.jmrt.2023.07.258

A. Nayeb-Hashemi, J.B. Clark, Phase Diagrams of Binary Magnesium Alloys (ASM International, Metals Park, 1988)

S. Ramesh, G. Anne, H.S. Nayaka, S. Sahu, M.R. Ramesh, J. Mater. Eng. Perform. 28, 2053 (2019). https://doi.org/10.1007/s11665-019-04007-0

P. Metalnikov, G. Ben-Hamu, K.S. Shin, Met. Mater. Int. 27, 1493 (2021). https://doi.org/10.1007/s12540-019-00529-3

Y. Song, E.-H. Han, D. Shan, C.D. Yim, B.S. You, Corros. Sci. 65, 322 (2012). https://doi.org/10.1016/j.corsci.2012.08.037

H. Zhao, L.-Q. Wang, Y.-P. Ren, B. Yang, S. Li, G.-W. Qin, Acta Metall. Sin. English Lett. 31, 575 (2018). https://doi.org/10.1007/s40195-018-0712-x

M.M. Zerankeshi, R. Alizadeh, E. Gerashi, M. Asadollahi, T.G. Langdon, J. Magnes. Alloy. 10, 1737 (2022). https://doi.org/10.1016/j.jma.2022.04.010

Y. Lu, Y. Huang, F. Feyerabend, R. Willumeit-Römer, K.U. Kainer, N. Hort, Magnes. Technol. (2016). https://doi.org/10.1002/9781119274803.ch67

K. Bryła, J. Horky, Mater. Trans. 64, 1709 (2023). https://doi.org/10.2320/matertrans.MT-MF2022056

E. Gerashi, R. Alizadeh, T.G. Langdon, J. Magnes. Alloy. 10, 313 (2021). https://doi.org/10.1016/j.jma.2021.09.009

H. Yan, X. Gong, J. Chen, M. Cheng, Met. Mater. Int. 27, 2249 (2021). https://doi.org/10.1007/s12540-019-00601-y

E. Koç, M.B. Kannan, M. Ünal, E. Candan, J. Alloys Compd. 648, 291 (2015). https://doi.org/10.1016/j.jallcom.2015.06.227

E. Gerashi, R. Alizadeh, R. Mahmudi, J. Mater. Res. Technol. 20, 3363 (2022). https://doi.org/10.1016/J.JMRT.2022.08.072

Y.F. Zheng, X.N. Gu, F. Witte, Mater. Sci. Eng. R Reports. 77, 1 (2014). https://doi.org/10.1016/j.mser.2014.01.001

F. Witte, J. Fischer, J. Nellesen, H.-A. Crostack, V. Kaese, A. Pisch, F. Beckmann, H. Windhagen, Biomaterials 27, 1013 (2006). https://doi.org/10.1016/j.biomaterials.2005.07.037

Z. Liu, R. Schade, B. Luthringer, N. Hort, H. Rothe, S. Müller, K. Liefeith, R. Willumeit-Römer, F. Feyerabend, Oxid. Med. Cell. Longev. (2017). https://doi.org/10.1155/2017/8091265

D. Tie, F. Feyerabend, W.-D. Mueller, R. Schade, K. Liefeith, K.U. Kainer, R. Willumeit, Eur. Cell. Mater. 25, 284 (2013). https://doi.org/10.22203/ecm.v025a20

M. Asadollahi, E. Gerashi, R. Alizadeh, R. Mahmudi, J. Mater. Res. Technol. 21, 4473 (2022). https://doi.org/10.1016/j.jmrt.2022.11.041

A. Dodangeh, M. Kazeminezhad, H. Aashuri, Mater. Sci. Eng. A 558, 371 (2012). https://doi.org/10.1016/j.msea.2012.08.014

M. Atari, S. Labbaf, S. Haghjooy Javanmard, J. Polym. Environ. (2023). https://doi.org/10.1007/s10924-023-02957-0

Y. Jin, C. Blawert, H. Yang, B. Wiese, F. Feyerabend, J. Bohlen, D. Mei, M. Deng, M.S. Campos, N. Scharnagl, others. Mater. Des. 195, 108980 (2020). https://doi.org/10.1016/j.matdes.2020.108980

S.W. Nam, W.T. Kim, D.H. Kim, T.S. Kim, Met. Mater. Int. 19, 205 (2013). https://doi.org/10.1007/s12540-013-2010-5

D.-B. Liu, B. Wu, X. Wang, M.-F. Chen, Rare Met. 34, 553 (2015). https://doi.org/10.1007/s12598-013-0052-y

E. Gerashi, M. Asadollahi, R. Alizadeh, R. Mahmudi, Mater. Sci. Eng. A 843, 143127 (2022). https://doi.org/10.1016/j.msea.2022.143127

M. Sabbaghian, R. Mahmudi, K.S. Shin, J. Magnes. Alloy. 7, 707 (2019). https://doi.org/10.1016/j.jma.2019.11.001

K. Yan, H. Liu, N. Feng, J. Bai, H. Cheng, J. Liu, F. Huang, J. Magnes. Alloy. 7, 305 (2019). https://doi.org/10.1016/j.jma.2019.02.006

R. Alizadeh, J. LLorca, Acta Mater. 186, 475 (2020). https://doi.org/10.1016/j.actamat.2020.01.028

K.B. Nie, X.J. Wang, K.K. Deng, F.J. Xu, K. Wu, M.Y. Zheng, J. Alloys Compd. 617, 979 (2014). https://doi.org/10.1016/j.jallcom.2014.08.148

M. Ascencio, M. Pekguleryuz, S. Omanovic, Corros. Sci. 87, 489 (2014). https://doi.org/10.1016/j.corsci.2014.07.015

S. Cai, T. Lei, N. Li, F. Feng, Mater. Sci. Eng. C 32, 2570 (2012). https://doi.org/10.1016/j.msec.2012.07.042

M. Sabbaghian, R. Mahmudi, K.S. Shin, Mater. Sci. Eng. A 792, 139828 (2020). https://doi.org/10.1016/j.msea.2020.139828

R.-C. Zeng, L. Sun, Y.-F. Zheng, H.-Z. Cui, E.-H. Han, Corros. Sci. 79, 69 (2014). https://doi.org/10.1016/j.corsci.2013.10.028

S. Bender, J. Goellner, A. Heyn, S. Schmigalla, Mater. Corros. 63, 707 (2012). https://doi.org/10.1002/maco.201106225

G. Song, A. Atrens, D. StJohn, Essent. Readings Magnes. Technol. (2016). https://doi.org/10.1007/978-3-319-48099-2_90

Y. Liu, D. Liu, C. You, M. Chen, Front. Mater. Sci. 9, 247 (2015). https://doi.org/10.1007/s11706-015-0299-3

M. Sun, G. Wu, W. Wang, W. Ding, Mater. Sci. Eng. A 523, 145 (2009). https://doi.org/10.1016/j.msea.2009.06.002

J. Chen, S. Wei, L. Tan, K. Yang, Mater. Technol. 34, 592 (2019). https://doi.org/10.1080/10667857.2019.1603657

E. Gerashi, M. Jamalpour, R. Alizadeh, S. Labbaf, R. Mahmudi, Mater. Lett. 330, 133224 (2023). https://doi.org/10.1016/j.matlet.2022.133224

F. El-Taib Heakal, A. Mohammed Fekry, M. Ziad Fatayerji, J. Appl. Electrochem. 39, 583 (2009). https://doi.org/10.1007/s10800-008-9696-y

Y. Xin, K. Huo, H. Tao, G. Tang, P.K. Chu, Acta Biomater. 4, 2008 (2008). https://doi.org/10.1016/j.actbio.2008.05.014

F.E.-T. Heakal, A.M. Fekry, M.Z. Fatayerji, J. Appl. Electrochem. 39, 583 (2009). https://doi.org/10.1007/s10800-008-9696-y

A.F. Lotfabadi, H.R. Bakhsheshi-Rad, M.H. Idris, E. Hamzah, M. Kasiri-Asgarani, Can. Metall. Q. 55, 53 (2016). https://doi.org/10.1179/1879139515Y.0000000031

X. Yan, P. Wan, L. Tan, M. Zhao, C. Shuai, K. Yang, Mater. Sci. Eng. B 229, 105 (2018). https://doi.org/10.1016/j.mseb.2017.12.033

Y. Jang, B. Collins, J. Sankar, Y. Yun, Acta Biomater. 9, 8761 (2013). https://doi.org/10.1016/j.actbio.2013.03.026

K.V. Kutniy, I.I. Papirov, M.A. Tikhonovsky, A.I. Pikalov, S.V. Sivtzov, L.A. Pirozhenko, V.S. Shokurov, V.A. Shkuropatenko, Materwiss. Werksttech. 40, 242 (2009). https://doi.org/10.1002/mawe.200900434

B.M. Wilke, L. Zhang, W. Li, C. Ning, C. Chen, Y. Gu, Appl. Surf. Sci. 363, 328 (2016). https://doi.org/10.1016/j.apsusc.2015.12.026

R. Rettig, S. Virtanen, J. Biomed. Mater. Res. Part A An Off. J. Soc. Biomater. Japanese Soc. Biomater. Aust. Soc. Biomater. Korean Soc. Biomater. 88, 359 (2009). https://doi.org/10.1002/jbm.a.31887

A. Bahmani, S. Arthanari, K.S. Shin, J. Magnes. Alloy. 8, 134 (2020). https://doi.org/10.1016/j.jma.2019.12.001

Y. Song, E.-H. Han, D. Shan, C.D. Yim, B.S. You, Corros. Sci. 60, 238 (2012). https://doi.org/10.1016/j.corsci.2012.03.030

J.-H. Dong, L.-L. Tan, Y.-B. Ren, K. Yang, Acta Metall. Sin. English Lett. 32, 305 (2019). https://doi.org/10.1007/s40195-018-0750-4

K. Chen, X. Xie, H. Tang, H. Sun, L. Qin, Y. Zheng, X. Gu, Y. Fan, Bioact. Mater. 5, 275 (2020). https://doi.org/10.1016/j.bioactmat.2020.02.014

M. Harjo, J. Torop, M. Järvekülg, T. Tamm, R. Kiefer, Polymers (Basel). 11, 1043 (2019). https://doi.org/10.3390/polym11061043

M. Zohrevand, M. Mohammadi-Zerankeshi, F. Nobakht-Farin, R. Alizadeh, R. Mahmudi, J. Mater. Res. Technol. 20, 1204 (2022). https://doi.org/10.1016/J.JMRT.2022.07.072

S. Zhang, J. Li, Y. Song, C. Zhao, X. Zhang, C. Xie, Y. Zhang, H. Tao, Y. He, Y. Jiang, Mater. Sci. Eng. C 29, 1907 (2009). https://doi.org/10.1016/j.msec.2009.03.001

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper. The authors declare the following financial interests/personal relationships which may be considered as potential competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Asadollahi, M., Alizadeh, R., Mahmudi, R. et al. Using Solution Heat Treatment and Multi Directional Forging to Improve the Mechanical and Corrosion Properties of an Mg–2Zn–0.2Ag Alloy. Met. Mater. Int. (2024). https://doi.org/10.1007/s12540-023-01602-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12540-023-01602-8