Abstract

We investigated an electrodeposition technique for fabricating a high-strength thin metallic foil as a current collector material in secondary batteries. To increase the strength and minimize the increase in electrical resistivity, copper–nickel (Cu–Ni) double-layered foils were considered and the grain structures of each layer were manipulated by controlling the electrodeposition solution and process conditions. Initially, a Cu electrodeposition process was developed to form a bamboo-like grain structure after annealing, which was followed by two Ni processes to produce a foil with a columnar or nano-crystalline grain structure. Subsequently, several foils were annealed at 190 °C for 10 min considering that current collectors experience a thermal load during battery manufacturing. Scanning and transmission electron microscopy-based crystallographic orientation mapping techniques indicated a remarkable change in the grain structure of the Cu foil owing to the grain growth after annealing; conversely, the Ni foil with the nano-crystalline grain structure was insensitive to annealing. By applying these processes to each material, four 10-µm-thick double-layered foils were fabricated. Among these foils, the foil with a nano-crystalline Ni layer exhibited the smallest change in material properties resulting in the highest tensile strength and moderate elongation after annealing. The tensile strength of the best double-layered foil was approximately three-fold higher than that of the single-layered Cu foil after annealing.

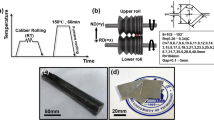

Graphical Abstract

Similar content being viewed by others

Data Availability

All data and materials support our published claims and comply with field standards.

Code Availability

All software applications or custom codes support our published claims and comply with field standards.

Change history

28 January 2024

A Correction to this paper has been published: https://doi.org/10.1007/s12540-023-01625-1

References

J.M. Tarascon, M. Armand, Nature 414, 359 (2001). https://doi.org/10.1038/35104644

L. Guo, D.B. Thornton, M.A. Koronfel, I.E. Stephens, M.P. Ryan, J. Phys. Energy 3, 032015 (2021). https://doi.org/10.1088/2515-7655/ac0c04

P. Zhu, D. Gastol, J. Marshall, R. Sommerville, V. Goodship, E. Kendrick, J. Power. Sources 485, 229321 (2021). https://doi.org/10.1016/j.jpowsour.2020.229321

F.J. Humphreys, M. Hatherly, Recrystallization and Related Annealing Phenomena (Pergamon Press, Oxford, 1995), pp.1–9

D.N. Lee, Texture and Related Phenomena, 2nd edn. (The Korean Institute of Metals and Materials, Seoul, 2014), pp. 280–484

H. Park, S.H. Kim, W.J. Lee, J.W. Ha, S.J. Kim, H.J. Lee, Met. Mater. Int. 27, 2220 (2021). https://doi.org/10.1007/s12540-020-00682-0

H. Park, W.J. Lee, J.H. Son, H.K. Shin, S.K. Hong, H.J. Lee, Met. Mater. Int. 28, 1881 (2022). https://doi.org/10.1007/s12540-021-01089-1

H.K. Shin, S.H. Kim, H. Park, H.J. Lee, J. Electrochem. Soc. 169, 102502 (2022). https://doi.org/10.1149/1945-7111/ac964e

S. Samiei, G. Dini, M. Ebrahimian-Hosseinabadi, Met. Mater. Int. 29, 192 (2023). https://doi.org/10.1007/s12540-022-01202-y

Z. Tang, W. Xiong, J. Zhang, Y. Zheng, C. Huang, Met. Mater. Int. 29, 1896 (2023). https://doi.org/10.1007/s12540-022-01361-y

Y. Xiang, J.J. Vlassak, Acta Mater. 54, 5449 (2006). https://doi.org/10.1016/j.actamat.2006.06.059

N.Q. Chinh, D. Olasz, A.Q. Ahmed, G. Sáfrán, J. Lendvai, T.G. Langdon, Mater. Sci. Eng. A 862, 144419 (2023). https://doi.org/10.1016/j.msea.2022.144419

E.N. Hahn, M.A. Meyers, Mater. Sci. Eng. A 646, 101 (2015). https://doi.org/10.1016/j.msea.2015.07.075

W.D. Nix, Metall. Trans. A 20, 2217 (1989). https://doi.org/10.1007/BF02666659

E.J. Arzt, Acta Mater. 46, 5611 (1998). https://doi.org/10.1016/S1359-6454(98)00231-6

X.Q. Liu, Z. Li, Z.J. Peng, R.X. Wang, Z.Q. Liu, Met. Mater. Int. (2023). https://doi.org/10.1007/s12540-023-01489-5

H. Liu, Y. Shen, J. Ma, P. Zheng, L. Zhang, J. Mater. Eng. Perform. 25, 3599 (2016). https://doi.org/10.1007/s11665-016-2245-7

J.S. Ibrahim, M.J.N.V. Prasad, P. Sarkar, K. Narasimhan, Met. Mater. Int. (2023). https://doi.org/10.1007/s12540-023-01520-9

C.S. Hau-Riege, Microelectron. Reliab. 44, 195 (2004). https://doi.org/10.1016/j.microrel.2003.10.020

T.P. Moffat, D. Wheeler, D. Josell, J. Electrochem. Soc. 151, C262 (2004). https://doi.org/10.1149/1.1651530

A. Kreider, Mechanism of SPS acceleration in a PEG containing copper plating bath, Ph.D. thesis (University of New Hampshire, 2012)

J.J. Kelly, N.Y. Yang, Electrodeposition of Ni from a sulfamate electrolyte, SAND Report (Sandia National Laboratories, 2001)

G. Wu, W. Zhu, Q. He, Z. Feng, T. Huang, L. Zhang, S. Schmidt, A. Godfrey, X. Huang, Nano Mater. Sci. 2(1), 50–57 (2020). https://doi.org/10.1016/j.nanoms.2020.03.006

I. Ghamarian, P. Samimi, G.S. Rohrer, P.C. Collins, Acta Mater. 130, 164–176 (2017). https://doi.org/10.1016/j.actamat.2017.03.041

P.F. Rottmann, K.J. Hemker, Scr. Mater. 141, 76 (2017). https://doi.org/10.1016/j.scriptamat.2017.07.029

B.Z. Cui, K. Han, Y. Xin, D.R. Waryoba, A.L. Mbaruku, Acta Mater. 55, 4429 (2007). https://doi.org/10.1016/j.actamat.2007.04.009

H.J. Lee, H.N. Han, D.H. Kim, U.-H. Lee, K.H. Oh, P.-R. Cha, Appl. Phys. Lett. 89, 161924 (2006). https://doi.org/10.1063/1.2364119

K. Lu, Nat. Rev. Mater. 1, 16019 (2016). https://doi.org/10.1038/natrevmats.2016.19

C.V. Thompson, Annu. Rev. Mater. Sci. 30, 159 (2000). https://doi.org/10.1146/annurev.matsci.30.1.159

A. Dulmaa, F.G. Cougnon, R. Dedoncker, D. Depla, Acta Mater. 212, 116896 (2021). https://doi.org/10.1016/j.actamat.2021.116896

Q. Zhao, S. Stalin, C.Z. Zhao, L.A. Archer, Nat. Rev. Mater. 5, 229 (2020). https://doi.org/10.1038/s41578-019-0165-5

Acknowledgements

This research was supported by the National Research Foundation of Korea (NRF) funded by the Ministry of Education (grant number NRF-2019M3A7B9072142). This work was also supported by the National Research Foundation of Korea (NRF) grant funded by the Korea Government (MSIT) (No. NRF-2021M3H4A6A01041234).

Funding

This research was supported by the National Research Foundation of Korea (NRF) funded by the Ministry of Education (grant number NRF-2019M3A7B9072142). This work was also supported by the National Research Foundation of Korea (NRF) grant funded by the Korea Government (MSIT) (No. NRF-2021M3H4A6A01041234).

Author information

Authors and Affiliations

Contributions

All authors contributed to the material preparation and data collection. Dr. S-DK helped us determine the grain structure of the nano-crystalline Ni foil using the TEM-based crystallographic mapping technique (ASTAR from NanoMEGAS). Dr. HP wrote the first draft of the manuscript and Dr. H-JL steered the overall direction of the manuscript. All authors commented on the previous version of the manuscript and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors have no conflicts of interest to declare that are relevant to the content of this article.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

The original online version of this article was revised due to the affiliation “Present Address: Research & Development Team, Korea Zinc Advanced Materials, Ulsan 45011, Republic of Korea” was incorrectly given for Author Hyo-Jong Lee but it should have been Sung-Jin Kim.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Park, H., Kim, SJ., Song, Yj. et al. Microstructure-controlled Electrodeposition of Mechanically Reliable Double-layered Thin Foils for Secondary Batteries. Met. Mater. Int. 30, 1430–1439 (2024). https://doi.org/10.1007/s12540-023-01576-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-023-01576-7