Abstract

Interfacial bonding behavior of 7050 aluminum alloy clad plates during hot-roll cladding under different vacuum degrees was investigated. The results demonstrated that the bonding effect of the interface was positively correlated with the vacuum degree. Due to severe surface oxidation at 105 Pa, the metal on both sides of the interface did not undergo metallurgical bonding and mainly maintained physical contact, with an ultimate tensile strength (UTS) of only 209 MPa across the interface. At 102 Pa, the large-scale migration of original interfacial grain boundary was still inhibited and continuous dynamic recrystallization occurred mainly at the interface with bulging only locally, which directly led to brittle fracture. At 10–1 Pa, significant discontinuous dynamic recrystallization (DDRX) occurred at the interface, resulting in the complete elimination of the original interface. And UTS across the interface was 338 MPa, reaching the level of the matrix. Therefore, interfacial metallurgical bonding could be achieved by reducing the oxidation of interface and further inducing DDRX during hot-roll cladding.

Graphical Abstract

Similar content being viewed by others

References

A. Azarniya, A.K. Taheri, K.K. Taheri, J. Alloy. Compd. 781, 945–983 (2019). https://doi.org/10.1016/j.jallcom.2018.11.286

T. Dursun, C. Soutis, Mater. Des. 56, 862–871 (2014). https://doi.org/10.1016/j.matdes.2013.12.002

Y. Li, H. Li, L. Katgerman, Q. Du, J. Zhang, L.Z. Zhuang, Prog. Mater. Sci. 117, 100741 (2021). https://doi.org/10.1016/j.pmatsci.2020.100741

X.W. She, X.Q. Jiang, P.Q. Wang, B.B. Tang, K. Chen, Y.J. Liu, W.N. Cao, Trans. Nonferrous Met. Soc. China. 30, 1780–1789 (2020). https://doi.org/10.1016/S1003-6326(20)65338-9

R. Nadella, D.G. Eskin, Q. Du, L. Katgerman, Prog. Mater. Sci. 53, 421–480 (2008). https://doi.org/10.1016/j.pmatsci.2007.10.001

X.D. Liu, Q.F. Zhu, Z.M. Li, C. Zhu, R. Wang, T. Jia, Z.H. Zhao, J.Z. Cui, Y.B. Zuo, Trans. Nonferrous Met. Soc. China. 31, 565–575 (2021). https://doi.org/10.1016/S1003-6326(21)65519-X

Y. Qiu, K.H. Zheng, X.T. Li, Y.J. Luo, P. Xia, M.Y. Liu, N. Zhou, Y.W. Jia, J. Mater. Res. Technol. 18, 2885–2895 (2022). https://doi.org/10.1016/j.jmrt.2022.03.177

W. Khalifa, Y. Tsunekawa, M. Okumiya, J. Mater. Process. Technol. 210, 2178–2187 (2010). https://doi.org/10.1016/j.jmatprotec.2010.08.008

X. Zhang, Z.A. Luo, G.M. Xie, H. Yu, Z.S. Liu, J.S. Yang, Mater. Sci. Eng. A 850, 143582 (2022). https://doi.org/10.1016/j.msea.2022.143582

N. Birks, G.H. Meier, F.S. Pettit, Introduction to High-Temperature Oxidation of Metals, 2nd edn. (Cambridge University Press, New York, 2006), pp.6–15

R.U. Din, K. Bordo, M.S. Jellesen, R. Ambat, Surf. Coat. Technol. 276, 106–115 (2015). https://doi.org/10.1016/j.surfcoat.2015.06.060

L.P.H. Jeurgens, W.G. Sloof, F.D. Tichelaar, E.J. Mittemeijer, J. Appl. Phys. 92, 1649–1656 (2002). https://doi.org/10.1063/1.1491591

E. Panda, L.P.H. Jeurgens, E.J. Mittemeijer, Corrosion Sci. 52, 2556–2564 (2010). https://doi.org/10.1016/j.corsci.2010.03.028

N. Bandaru, D. Ajmera, K. Manwani, S. Majhi, E. Panda, Trans. Indian Inst. Met. 70, 1269–1275 (2017). https://doi.org/10.1007/s12666-016-0920-x

J.Q. Yu, G.Q. Zhao, Mater. Charact. 138, 56–66 (2018). https://doi.org/10.1016/j.matchar.2018.01.052

J.Q. Yu, G.Q. Zhao, W.C. Cui, C.S. Zhang, L. Chen, J. Mater. Process. Technol. 247, 214–222 (2017). https://doi.org/10.1016/j.jmatprotec.2017.04.030

J.Q. Yu, G.Q. Zhao, C.S. Zhang, L. Chen, Mater. Sci. Eng. A 682, 679–690 (2017). https://doi.org/10.1016/j.msea.2016.11.089

Z.C. Zhu, Y. He, X.J. Zhang, H.Y. Liu, X. Li, Mater. Sci. Eng. A 669, 344–349 (2016). https://doi.org/10.1016/j.msea.2016.05.066

N. Malik, P.A. Carvalho, E. Poppe, T.G. Finstad, J. Appl. Phys. 119, 205303 (2016). https://doi.org/10.1063/1.4952709

X. Xu, X.W. Ma, G.Q. Zhao, X.X. Chen, Y.X. Wang, J. Alloy. Compd. 867, 159043 (2021). https://doi.org/10.1016/j.jallcom.2021.159043

X. Xu, X.W. Ma, G.Q. Zhao, Y.X. Wang, X.X. Chen, Mater. Des. 210, 110043 (2021). https://doi.org/10.1016/j.matdes.2021.110043

N. Kurgan, Int. J. Adv. Manuf. Technol. 71, 2115–2124 (2014). https://doi.org/10.1007/s00170-014-5650-9

J.Y. Zhang, B. Xu, N. Haq Tariq, M.Y. Sun, D.Z. Li, Y.Y. Li, J. Mater. Sci. Technol. 46, 1–11 (2020). https://doi.org/10.1016/j.jmst.2019.11.015

J.Y. Zhang, B. Xu, N.U.H. Tariq, M.Y. Sun, D.Z. Li, Y.Y. Li, J. Mater. Sci. Technol. 40, 54–63 (2020). https://doi.org/10.1016/j.jmst.2019.08.044

R. Luo, Y. Cao, H.K. Bian, L.L. Chen, C.T. Peng, F.Y. Cao, L.X. Ouyang, Y. Qiu, Y.J. Xu, A. Chiba, X.N. Cheng, Mater. Charact. 178, 111203 (2021). https://doi.org/10.1016/j.matchar.2021.111203

C.C. Xu, H. He, Z.G. Xue, L.X. Li, Mater. Charact. 171, 110801 (2021). https://doi.org/10.1016/j.matchar.2020.110801

C.L. Xu, J.W. Huang, F.Q. Jiang, Y.G. Jiang, Mater. Charact. 183, 111629 (2022). https://doi.org/10.1016/j.matchar.2021.111629

J.J. Zhang, Y.P. Yi, H.L. He, S.Q. Huang, X.C. Mao, W.F. Guo, W. You, Y.L. Guo, F. Dong, J.G. Tang, Mater. Charact. 181, 111492 (2021). https://doi.org/10.1016/j.matchar.2021.111492

X. Xu, X.W. Ma, S.B. Yu, G.Q. Zhao, Y.X. Wang, X.X. Chen, Mater. Charact. 167, 110486 (2020). https://doi.org/10.1016/j.matchar.2020.110486

T.F. Chung, Y.L. Yang, C.L. Tai, M. Shiojiri, C.N. Hsiao, C.S. Tsao, W.C. Li, Z. Shi, J. Lin, H.R. Chena, J.R. Yang, Mater. Sci. Eng. A 815, 141213 (2021). https://doi.org/10.1016/j.msea.2021.141213

Q.H. Zang, D. Feng, Y.S. Lee, H.M. Chen, M.S. Kim, H.W. Kim, J. Alloy. Compd. 847, 156481 (2020). https://doi.org/10.1016/j.jallcom.2020.156481

R.J. Dai, K.K. Deng, C.J. Wang, K.B. Nie, G.W. Zhang, W. Liang, Mater. Sci. Eng. A 848, 143388 (2022). https://doi.org/10.1016/j.msea.2022.143388

S. Choi, J. Jeon, N. Seo, S.B. Son, S.J. Lee, Met. Mater.-Int. 27, 449–455 (2021). https://doi.org/10.1007/s12540-020-00910-7

A. Abolhasani, A. Zarei-Hanzaki, H.R. Abedi, M.R. Rokni, Mater. Des. 34, 631–636 (2012). https://doi.org/10.1016/j.matdes.2011.05.019

G.S. Peng, K.H. Chen, S.Y. Chen, H.C. Fang, Mater. Sci. Eng. A 641, 237–241 (2015). https://doi.org/10.1016/j.msea.2015.06.058

Y. Zhang, J.F. Jiang, Y. Wang, G.F. Xiao, Y.Z. Liu, M.J. Huang, J. Alloy. Compd. 893, 162311 (2022). https://doi.org/10.1016/j.jallcom.2021.162311

J.C. Li, X.D. Wu, B. Liao, X.M. Lin, L.F. Cao, Trans. Nonferrous Met. Soc. China 31, 1902–1915 (2021). https://doi.org/10.1016/S1003-6326(21)65625-X

S. Jin, B. Kang, T. Kong, S.H. Hong, H.J. Shin, R.S. Ruoff, J. Alloy. Compd. 853, 157390 (2021). https://doi.org/10.1016/j.jallcom.2020.157390

L.Y. Zhou, W.X. Chen, S.B. Feng, M.Y. Sun, B. Xu, D.Z. Li, J. Mater. Sci. Technol. 43, 92–103 (2020). https://doi.org/10.1016/j.jmst.2020.01.010

R. Fu, Y.C. Huang, Y. Liu, H. Li, Met. Mater. Int. 29, 2605–2622 (2023). https://doi.org/10.1007/s12540-023-01397-8

B.C. Xie, B.Y. Zhang, Y.Q. Ning, M.W. Fu, J. Alloy. Compd. 786, 636–647 (2019). https://doi.org/10.1016/j.jallcom.2019.01.334

J.J. Zhang, Y.P. Yi, S.Q. Huang, X.C. Mao, H.L. He, J.G. Tang, W.F. Guo, F. Dong, Mater. Sci. Eng. A 804, 140650 (2021). https://doi.org/10.1016/j.msea.2020.140650

K. Huang, R.E. Logé, Mater. Des. 111, 548–574 (2016). https://doi.org/10.1016/j.matdes.2016.09.012

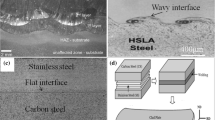

B.X. Liu, J.Y. Wei, M.X. Yang, F.X. Yin, K.C. Xu, Vacuum 154, 250–258 (2018). https://doi.org/10.1016/j.vacuum.2018.05.022

S. Wang, B.X. Liu, C.X. Chen, J.H. Feng, F.X. Yin, J. Alloy. Compd. 766, 517–526 (2018). https://doi.org/10.1016/j.jallcom.2018.06.109

X. Zhang, Z.A. Luo, Z.S. Liu, M.K. Wang, H. Yu, Y.Y. Feng, G.M. Xie, Mater. Sci. Eng. A 860, 144310 (2022). https://doi.org/10.1016/j.msea.2022.144310

B.J. Xie, M.Y. Sun, B. Xu, C.Y. Wang, D.Z. Li, Y.Y. Li, Mater. Des. 157, 437–446 (2018). https://doi.org/10.1016/j.matdes.2018.08.003

Acknowledgements

This work was financially supported by the National Key Research and Development Program of China (Grant No. 2018YFA0707300), the National Natural Science Foundation of China (Grant No. 52105322) and the Key Research and Development Program projects of Shandong (Grant No. 2020CXGC010304).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhang, X., Luo, Za., Yang, Js. et al. Effect of Vacuum Degrees on Interfacial Bonding Behavior of 7050 Aluminum Alloy Clad Plates During Hot-Roll Cladding. Met. Mater. Int. 30, 469–482 (2024). https://doi.org/10.1007/s12540-023-01505-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-023-01505-8