Abstract

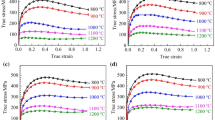

Although additive manufacturing with 3XX austenitic stainless steel has been widely established owing to its high strength, good corrosion resistance and weldability, the substitution of Mn for Ni is required to overcome the price increment of stainless steels due to the high demand for Ni. In this study, the mechanical properties of a laser-powder bed fusion processed Fe-15Cr-6Ni-6Mn alloy were investigated. Because appropriate processing parameters (e.g., laser power and laser scan speed) for this alloy have not yet been established, the optimized processing parameters were obtained using a response surface method. Based on the processing optimization, the present additively manufactured Fe-15Cr-6Ni-66Mn alloy achieved 800 MPa tensile strength and 40% elongation, which can be compared to recent additively manufactured 3XX stainless steels. In addition, the low stacking fault energy of the Fe-15Cr-6Ni-6Mn alloy induces a subsequent γ-austenite → ε-martensite → α’-martensite phase transformation, which provides an extra-strain-hardening capability in the middle of plastic deformation stage. Meanwhile, in a cryogenic temperature, accelerated martensitic transformation occurs due to the reduced stacking fault energy at a low temperature that degrades ductility after tensile test. The results show that the substitution of Ni with Mn is a good solution for the development of low-cost stainless steel, but additional chemical content tuning required to overcome ductility degradation at a cryogenic environment.

Graphical Abstract

Similar content being viewed by others

Data Availability

The raw/processed data required to reproduce these findings cannot be shared at this time as the data also forms part of an ongoing study.

References

Z. Wang, T.A. Palmer, A.M. Beese, Effect of processing parameters on microstructure and tensile properties of austenitic stainless steel 304L made by directed energy deposition additive manufacturing. Acta Mater. 110, 226 (2016)

J.V. Gordon, C.V. Haden, H.F. Nied, R.P. Vinci, D.G. Harlow, Fatigue crack growth anisotropy, texture and residual stress in austenitic steel made by wire and arc additive manufacturing. Mater. Sci. Eng. A 724, 431 (2018)

X. Chen, J. Li, X. Cheng, H. Wang, Z. Huang, Effect of heat treatment on microstructure, mechanical and corrosion properties of austenitic stainless steel 316L using arc additive manufacturing. Mater. Sci. Eng. A 715, 307 (2018)

Y.M. Wang, T. Voisin, J.T. McKeown, J. Ye, N.P. Calta, Z. Li, Z. Zeng, Y. Zhang, W. Chen, T.T. Roehling, R.T. Ott, M.K. Santala, P.J. Depond, M.J. Matthews, A.V. Hamza, T. Zhu, Additively manufactured hierarchical stainless steels with high strength and ductility. Nat. Mater. 17, 63 (2018)

J. Jeong, Y. Lee, J.M. Park, D.J. Lee, I. Jeon, H. Sohn, H.S. Kim, T.-H. Nam, H. Sung, J.B. Seol, J.G. Kim, Metastable δ-ferrite and twinning-induced plasticity on the strain hardening behavior of directed energy deposition-processed 304L austenitic stainless steel. Addit. Manuf. 47, 102363 (2021)

G.M. Karthik, E.S. Kim, P. Sathiyamoorthi, A. Zargaran, S.G. Jeong, R. Xiong, S.H. Kang, J.-W. Cho, H.S. Kim, Delayed deformation-induced martensite transformation and enhanced cryogenic tensile properties in laser additive manufactured 316L austenitic stainless steel. Addit. Manuf. 47, 102314 (2021)

C.J. Todaro, M.A. Easton, D. Qiu, M. Brandt, D.H. StJohn, M. Qian, Grain refinement of stainless steel in ultrasound-assisted additive manufacturing. Addit. Manuf. 37, 101632 (2021)

J.G. Kim, J.B. Seol, J.M. Park, H. Sung, S.H. Park, H.S. Kim, Effect of cell network structure on the strength of additively manufactured stainless steels. Met. Mater. Int. 27, 2614 (2021)

L. Liu, Q. Ding, Y. Zhong, J. Zou, J. Wu, Y.-L. Chiu, J. Li, Z. Zhang, Q. Yu, Z. Shen, Dislocation network in additive manufactured steel breaks strength-ductility trade off. Mater. Today 21, 354 (2018)

S.-W. Baek, E.J. Song, J.H. Kim, M. Jung, U.B. Baek, S.H. Nahm, Hydrogen embrittlement of 3-D printing manufactured austenitic stainless steel part for hydrogen service. Scr. Mater. 130, 87 (2017)

D.-H. Lee, B. Sun, S. Lee, D. Ponge, E.A. Jagle, D. Raabe, Comparative study of hydrogen embrittlement resistance between additively and conventionally manufactured 304L austenitic stainless steels. Mater. Sci. Eng. A 803, 140499 (2021)

K.M. Bertsch, A. Nagao, B. Rankouhi, B. Kuehl, D.J. Thoma, Hydrogen embrittlement of additively manufactured austenitic stainless steel 316L. Corros. Sci. 192, 109790 (2021)

B. Clausen, C.R. D’Elia, M.B. Prime, M.R. Hill, J.E. Bishop, K.L. Johnson, B.H. Jared, K.M. Allen, D.K. Balch, R.A. Roach, D.W. Brown, Complementary measurements of residual stresses before and after base plate removal in an intricate additively-manufactured stainless-steel valve housing. Addit. Manuf. 36, 101555 (2020)

T. Peng, Y. Wang, Y. Zhu, Y. Yang, Y. Yang, R. Tang, Life cycle assessment of selective-laser-melting-produced hydraulic valve body with integrated design and manufacturing optimization: a cradle-to-gate study. Addit. Manuf. 36, 101530 (2020)

J.M. Waller, R.L. Saulsberry, B.H. Parker, K.L. Hodges, E.R. Burke, M. Taminger, Summary of NDE of additive manufacturing efforts in NASA. AIP Conf. Proc. 51, 1650 (2015)

A.C. Ozdemir, K. Bulus, K. Zor, Medium- to long-term nickel price forecasting using LSTM and GRU networks. Resour. Policy 78, 102906 (2022)

A. Pardo, M.C. Merino, A.E. Coy, F. Viejo, R. Arrabal, E. Matykina, Pitting corrosion behaviour of austenitic stainless steels—combining effects of Mn and Mo additions. Corros. Sci. 50, 1796 (2008)

J.A. Brooks, Weldability of high N, high Mn austenitic stainless steel. Weld. J. 54, 189 (1975)

D.B. Lee, Atmospheric oxidation of Fe-16Cr-6Ni-6Mn-1.7Mo stainless steel between 700 and 900 ℃. Korean J. Met. Mater. 49, 153 (2011)

X. Liu, L. Liu, F. Sui, H. Bi, E. Chang, M. Li, Influence of Cu on the microstructure and corrosion resistance of cold-rolled type 204 stainless steels. J. Solid State Electrochem. 24, 1197 (2020)

M.J. Joseph, M.A. Jabbar, Effect of aging process on the microstructure, corrosion resistance and mechanical properties of stainless steel AISI 204. Case Stud. Constr. Mater. 11, e00253 (2019)

W. Chuaiphan, L. Srijaroenpramong, Microstructure, mechanical properties and pitting corrosion of TIG weld joints alternative low-cost austenitic stainless steel grade 216. J. Adv. Join. Process. 2, 100027 (2020)

J. Richter, G. Bartzsch, S. Scherbring, A. Bolender, M. Vollmer, J. Mola, O. Volkova, T. Niendorf, Metastable CrMnNi steels processed by laser powder bed fusion: experimental assessment of elementary mechanisms contributing to microstructure, properties and residual stress. Sci. Rep. 12, 21862 (2022)

J. Günther, R. Lehnert, R. Wagner, C. Burkhardt, M. Wendler, O. Volkova, H. Biermann, T. Niendorf, Effect of compositional variation induced by EBM processing on deformation behavior and phase stability of austenitic Cr-Mn-Ni TRIP steel. JOM 72, 1052 (2020)

Q.-X. Dai, A.-D. Wang, X.-N. Cheng, X.-M. Luo, Stacking fault energy of cryogenic austenitic steels. Chin. Phys. 11, 596 (2002)

H. Irrinki, M. Dexter, B. Barmore, R. Enneti, S. Pasebani, S. Badwe, J. Stitzel, R. Malhotra, S.V. Atre, Effects of powder attributes and laser powder bed fusion (L-PBF) process conditions on the densification and mechanical properties of 17–4 PH stainless steel. JOM 68, 860 (2016)

C. Garcia-Cabezon, M.A. Castro-Sastre, A.I. Fernandez-Abia, M.-L. Rodriguez-Mendez, F. Martin-Pedrosa, Microstructure–hardness–corrosion performance of 17–4 precipitation hardening stainless steels processed by selective laser melting in comparison with commercial alloy. Met. Mater. Int. 28, 2652 (2022)

M. Leary, M. Mazur, J. Elambasseril, M. McMillan, T. Chirent, Y. Sun, M. Qian, M. Easton, M. Brandt, Selective laser melting (SLM) of AlSi12Mg lattice structures. Mater. Des. 98, 344 (2016)

J.-H. Park, G.B. Bang, K.-A. Lee, Y. Son, Y.H. Song, B.-S. Lee, W.R. Kim, H.G. Kim, Effect of preheating temperature on microstructural and mechanical properties of Inconel 718 fabricated by selective laser melting. Met. Mater. Int. 28, 2836 (2022)

Y. Lee, E.S. Kim, S. Park, J.M. Park, J.B. Seol, H.S. Kim, T. Lee, H. Sung, J.G. Kim, Effects of laser power on the microstructure evolution and mechanical properties of Ti–6Al–4V alloy manufactured by direct energy deposition. Met. Mater. Int. 28, 197 (2022)

B. AlMangour, J. Cheng, D. Grzesiak, Y.-J. Hwang, K.-A. Lee, Fundamental study on the development of pure magnesium parts by additive manufacturing: an experimental and computational analysis. Met. Mater. Int. 29, 429 (2023)

T. Bhardwaj, M. Shukla, C.P. Paul, K.S. Bindra, Direct energy deposition—laser additive manufacturing of titanium-molybdenum alloy: parametric studies, microstructure and mechanical properties. J. Alloy. Compd. 787, 1238 (2019)

M. Gwak, J.Y. Park, S.G. Jeong, J.B. Seol, H. Sung, S. Kim, H.S. Kim, J.G. Kim, Optimization of laser-powder bed fusion processed Fe–4.5Si alloy via response surface methodology. Steel Res. Int. 94, 2200155 (2023)

P. Zhou, M.X. Huang, On the mechanisms of different work-hardening stages in twinning-induced plasticity steels. Metall. Mater. Trans. A 46, 5080 (2015)

H.D. Park, J.W. Won, J. Moon, H.S. Kim, H. Sung, J.B. Seol, J.W. Bae, J.G. Kim, Fe55Co17.5Ni10Cr12.5Mo5 high-entropy alloy with outstanding cryogenic mechanical properties driven by deformation-induced phase transformation behavior. Met. Mater. Int. 29, 95 (2023)

H. Idrissi, K. Renard, D. Schryvers, P.J. Jacques, On the relationship between the twin internal structure and the work-hardening rate of TWIP steels. Scr. Mater. 63, 961 (2010)

J.W. Bae, J.B. Seol, J. Moon, S.S. Sohn, M.J. Jang, H.Y. Um, B.-J. Lee, H.S. Kim, Exceptional phase-transformation strengthening of ferrous medium-entropy alloys at cryogenic temperatures. Acta Mater. 161, 388 (2018)

R.M. Latanision, A.W. Ruff, The temperature dependence of stacking fault energy in Fe-Cr-Ni alloys. Metall. Trans. 2, 505 (1971)

J. Hou, W. Chen, Z. Chen, K. Zhang, A. Huang, Microstructure, tensile properties and mechanical anisotropy of selective laser melted 304L stainless steel. J. Mater. Sci. Technol. 48, 63 (2020)

K. Guan, Z. Wang, M. Gao, X. Li, X. Zeng, Effects of processing parameters on tensile properties of selective laser melted 304 stainless steel. Mater. Des. 50, 581 (2013)

T.R. Smith, J.D. Sugar, C.S. Marchi, J.M. Schoenung, Strengthening mechanisms in directed energy deposited austenitic stainless steel. Acta Mater. 164, 728 (2019)

S. Wei, J. Kim, C.C. Tasan, Boundary micro-cracking in metastable Fe45Mn35Co10Cr10 high-entropy alloys. Acta Mater. 168, 76 (2019)

D. Molnár, X. Sun, S. Lu, W. Li, G. Engberg, L. Vitos, Effect of temperature on the stacking fault energy and deformation behaviour in 316L austenitic stainless steel. Mater. Sci. Eng. A 759, 490 (2019)

S. Allain, J.-P. Chateau, O. Bouaziz, S. Migot, N. Guelton, Correlations between the calculated stacking fault energy and the plasticity mechanisms in Fe–Mn–C alloys. Mater. Sci. Eng. A 387–389, 158 (2004)

R. Fussik, M. Walter, W. Theisen, S. Weber, Investigation of austenitic FeCrNi steels with regard to stacking-fault energy and thermal austenite stability. Materialia 3, 265 (2018)

H. Song, D.G. Kim, D.W. Kim, M.C. Jo, Y.H. Jo, W. Kim, H.S. Kim, B.-J. Lee, S. Lee, Effects of strain rate on room- and cryogenic-temperature compressive properties in metastable V10Cr10Fe45Co35 high-entropy alloy. Sci. Rep. 9, 6163 (2019)

Y.H. Jo, J. Yang, K.-Y. Doh, W. An, D.W. Kim, H. Sung, D. Lee, H.S. Kim, S.S. Sohn, S. Lee, Analysis of damage-tolerance of TRIP-assisted V10Cr10Fe45Co30Ni5 high-entropy alloy at room and cryogenic temperatures. J. Alloy. Compd. 844, 156090 (2020)

S. Martin, S. Wolf, S. Decker, L. Krüger, U. Martin, Deformation bands in high-alloy austenitic 16Cr6Mn6Ni TRIP steel: phase transformation and its consequences on strain hardening at room temperature. Steel Res. Int. 86, 1187 (2015)

S. Martin, S. Wolf, U. Martin, L. Krüger, D. Rafaja, Deformation mechanisms in austenitic TRIP/TWIP steel as a function of temperature. Metall. Mater. Trans. A 47, 49 (2016)

M.C. McGrath, D.C. Van Aken, N.I. Medvedeva, J.E. Medvedeva, Work hardening behavior in steel with multiple TRIP mechanisms. Metall. Mater. Trans. A 44, 4634 (2013)

G. Song, N.K. Aragon, I. Ruy, S.W. Lee, Low-temperature failure mechanism of [001] niobium micropillars under uniaxial tension. J. Mater. Res. 36, 2371 (2021)

Acknowledgements

J.G.K. acknowledges the financial support from the National Research Foundation of Korea (NRF) grant funded by the Korean government (MSIT) (NRF-2022R1G1A1007479) and the kind support of the POSCO Science Fellowship of the POSCO TJ Park Foundation.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Park, J.Y., Kim, B.J. & Kim, J.G. Mechanical Properties of Laser-Powder Bed Fusion Processed Fe-15Cr-6Ni-6Mn Multi-phase Steel at Room and Cryogenic Temperatures. Met. Mater. Int. 29, 3521–3531 (2023). https://doi.org/10.1007/s12540-023-01477-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-023-01477-9