Abstract

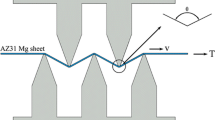

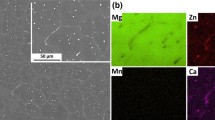

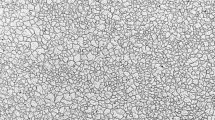

The pulsed current effect on the bending formability and microstructure evolution of the Mg–2.5Nd–0.5Zn–0.5Zr (wt%) alloy sheet was systematically studied at near room temperature (20 ~ 45 ℃). The results showed that the bending ability of the alloy could be significantly improved by the pulsed current. Specifically, compared with the non-electrically-assisted bending, the limiting bending depth (from 5.05 to 14.82 mm) and limiting bending angle(from 57 to 145°) of the alloy were increased by 193.5% and 154.3%, respectively, and the bending yield strength (from 252 to 162 MPa) decreased by 35.7%. When the peak current density was 12.1 A/mm2 (EA12), the limiting bending angle reached 145°, and there was no crack on the outer surface of the bending sample. The main reason was that the pulsed current promoted the dislocation movement, which was conducive to the activation of basal slip and non-basal slip to maintain deformation compatibility. The deformation mechanism of electrically-assisted bending samples showed that {10–12} twin dominated in the compression zone, while basal slip dominated in the tension zone. In addition, the effects of peak current density on microstructure, texture evolution and fracture mechanism were analyzed in detail. It provided important theoretical guidance for mastering the bending-forming mechanism of rare-earth magnesium alloys.

Graphical Abstract

Similar content being viewed by others

References

L. Hu, M. Lang, L. Shi, M. Li, T. Zhou, C. Bao, M. Yang, J. Magnes. Alloy (2021). https://doi.org/10.1016/j.jma.2021.07.008

W. Sun, X. Qiao, M. Zheng, C. Xu, S. Kamado, X. Zhao, H. Chen, N. Gao, M. Starink, Acta Mater. 151, 260–270 (2018)

C. He, J. Zhou, Y. Yang, B. Jiang, M. Yuan, Z. Dong, Y. Chai, W. He, G. Huang, D. Zhang, F. Pan, J. Mater. Sci. Technol. 131, 167–176 (2022)

X. Liu, H. Yang, B. Zhu, Y. Wu, W. Liu, C. Tang, J. Magnes. Alloy. 10, 1096–1108 (2022)

R. Li, H. Li, H. Pan, D. Xie, J. Zhang, D. Fang, Y. Dai, D. Zhao, H. Zhang, Scripta Mater. 193, 142–146 (2021)

J. Hu, Y. Su, J. He, D. Fang, J. Zhu, X. Meng, Mater. Res. Express. 9, 016508 (2022)

X. Wang, J. Xu, D. Shan, B. Guo, J. Cao, Int. J. Plast. 85, 230–257 (2016)

H. Xie, X. Dong, F. Peng, Q. Wang, K. Liu, X. Wang, F. Chen, J. Mater. Process. Tech. 227, 88–95 (2016)

A. Jordan, B. Kinsey, J. Mater. Process. Tech. 221, 1–12 (2015)

Y. Liu, M. Wan, B. Meng, Int. J. Mach. Tool. Manu. 162, 103689 (2021)

K. Mori, T. Maeno, K. Mongkolkaji, J. Mater. Process. Tech. 213, 508–514 (2013)

Z. Xu, T. Jiang, J. Huang, L. Peng, X. Lai, M. Fu, Int. J. Mach. Tool. Manu. 175, 103871 (2022)

Z. Deng, X. Li, S. Wang, X. Li, D. Chen, X. Xiao, Mater. Character 190, 112046 (2022)

G. Zhao, J. Fan, H. Zhang, Q. Zhang, J. Yang, H. Dong, B. Xu, Mater. Sci. Eng. A 731, 54–60 (2018)

J. Kuang, X. Du, X. Li, Y. Yang, A. Luo, G. Tang, Scripta Mater. 114, 151–155 (2016)

X. Li, X. Li, J. Zhu, X. Ye, G. Tang, Scripta Mater. 112, 23–27 (2016)

H. Xiao, X. Xia, S. Huang, Q. Chen, G. Zhao, Z. Zhao, Y. Wang, S. Chai, F. Peng, J. Alloy. Compd. 900, 163425 (2022)

H. Xiao, S. Jiang, K. Zhang, Y. Jia, C. Shi, Z. Lu, J. Jiang, J. Alloy. Compd. 814, 152257 (2020)

X. Xie, H. Yu, J. Mater. Process. Tech. 310, 117771 (2022)

H. Xie, Q. Wang, K. Liu, F. Peng, X. Dong, J. Wang, J. Mater. Process. Tech. 219, 321–327 (2015)

X. Wang, J. Xu, D. Shan, B. Guo, J. Cao, Mater. Des. 127, 134–143 (2017)

T. Lee, J. Magargee, M. Ng, J. Cao, Int. J. Plast. 94, 44–56 (2017)

M. Lee, J. Yu, M. Bae, J. Won, T. Lee, J. Mater. Res. Technol. 15, 5706–5711 (2021)

J. Magargee, F. Morestin, J. Cao, J. Eng. Mater. Technol. 135, 041003 (2013)

J. Lee, S. Kim, Y. Kim, S. Park, J. Alloy. Compd. 787, 519–526 (2019)

J. Lee, Y. Kim, S. Kim, J. Lee, M. Kim, S. Choi, B. Moonm, Y. Kim, S. Park, J. Magnes. Alloy. 7, 648–660 (2019)

J.U. Lee, G.M. Lee, S.H. Park, J. Magnes. Alloy. 10, 2238–2251 (2022). https://doi.org/10.1016/j.jma.2021.01.011

W. Wang, W. Zhang, W. Chen, G. Cui, E. Wang, J. Alloy. Compd. 737, 505–514 (2018)

S. Wang, J. Yang, J. Pan, H. Wang, W. Zhang, Y. Sun, X. Dai, J. Alloy. Compd. 911, 164987 (2022)

S. Hong, S. Park, Chong S. Lee, Acta Mater. 58, 5873–5885 (2010)

B. Guan, Y. Xin, X. Huang, P. Wu, Q. Liu, Acta Mater. 173, 142–152 (2019)

X. Xiao, S. Xu, D. Sui, H. Zhang, Mater. Lett. 288, 129362 (2021)

S. Sahoo, S. Biswas, L. Toth, P. Gautam, B. Beausir, Int. J. Plast. 128, 102660 (2020)

W. Feather, S. Ghorbanpour, D. Savage, M. Ardeljan, M. Jahedi, B. McWilliams, N. Gupta, C. Xiang, S. Vogel, M. Knezevic, Int. J. Plast. 120, 180–204 (2019)

X. Wang, B. Zhou, H. Huang, J. Niu, S. Guan, G. Yuan, J. Magnes. Alloy. (2022). https://doi.org/10.1016/j.jma.2022.07.007

J. Yan, W. Li, H. Liu, Y. Shen, Scripta Mater. 167, 86–90 (2019)

S. Wang, W. Zhang, H. Wang, J. Yang, W. Chen, G. Cui, G. Wang, Mater. Sci. Eng. A 803, 140488 (2021)

Z. Shan, J. Yang, J. Fan, H. Zhang, Q. Zhang, Y. Wu, W. Li, H. Dong, B. Xu, J. Magnes. Alloy. 9, 548–559 (2021)

H. Guo, X. Zeng, J. Fan, H. Zhang, Q. Zhang, W. Li, H. Dong, B. Xu, J. Mater. Sci. Technol. 35, 1113–1120 (2019)

Q. Xu, G. Tang, Y. Jiang, Mater. Sci. Eng. A 528, 4431–4436 (2011)

Q. Ma, B. Li, W. Whittington, A. Oppedal, P. Wang, M. Horstemeyer, Acta Mater. 67, 102–115 (2014)

G. Lee, J. Lee, S. Park, J. Mater. Res. Technol. 12, 1039–1050 (2021)

G. Lee, J. Lee, S. Park, J. Alloys. Compd. 918, 165613 (2022)

G.M. Lee, J.U. Lee, S.H. Park, J. Magnes. Alloy. (2022). https://doi.org/10.1016/j.jma.2021.11.029

J.U. Lee, S.-H. Kim, D.H. Lee, H.J. Kim, Y.M. Kim, S.H. Park, J. Magnes. Alloy. 10, 2475–2490 (2022)

G.M. Lee, J.U. Lee, S.H. Park, Mater. Sci. Eng. A 855, 143940 (2022)

L. Jin, J. Dong, J. Sun, A. Luo, Int. J. Plast. 72, 218–232 (2015)

J. Singh, M. Kim, S. Choi, Int. J. Plast. 117, 33–57 (2019)

M. Zhou, Y. Xu, Y. Liu, M. Duan, Z. Xia, L. Huang, R. Zhu, H. Ye, L. Peng, Y. Wu, Y. Liu, Mater. Sci. Eng. A 828, 141881 (2021)

Acknowledgements

This work was supported by National Natural Science Foundation of China (No. 51905123) and the Development Plan in Shandong Province (Grant No. 2020CXGC010303).

Author information

Authors and Affiliations

Contributions

WZ: Conceptualization, Formal analysis, Supervision. SW: Conceptualization, Writing-original draft, Formal analysis, carried out the experiment, planned the experiments. JY: Conceptualization, Writing-original draft, Formal analysis, planned the experiments. JP: carried out the experiment.

Corresponding author

Ethics declarations

Conflict Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhang, W., Wang, S., Pan, J. et al. Extraordinary Bending Formability of Mg–2.5Nd–0.5Zn–0.5Zr Alloy Sheet Through Pulsed Current. Met. Mater. Int. 29, 3371–3384 (2023). https://doi.org/10.1007/s12540-023-01450-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-023-01450-6