Abstract

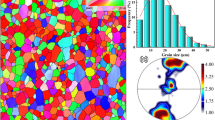

In this work, a bimodal grain structure was developed for commercial purity Ti(CP-Ti) via powder metallurgy processing, followed by free hot forging and then heat treatment. The bi-modal grains were characterized with electron backscatter diffraction. The mechanical tests showed that in comparison to the uniform and equiaxed grain structure, the bimodal grains improved the yield strength of CP-Ti significantly, while it maintains a merely changed ultimate tensile strength and elongation to failure. In addition, an interesting yield plateau was observed in the bimodal CP-Ti. To explore underlying mechanisms behind the phenomenon, the microstructures of the samples before and after testing were carefully examined. The results revealed that geometrically necessary dislocations accumulating at the interface between coarse and fine grains induced back stress hardening, which together with the statistically stored dislocations also accounted for the yield plateau in the bimodal CP-Ti.

Graphical abstract

Similar content being viewed by others

Data Availability

The raw/processed data required to reproduce these findings cannot be shared at this time as the data also forms part of an ongoing study.

References

X.-Q. Wang, Y.-S. Zhang, W.-Z. Han, Design of high strength and wear-resistance β-Ti alloy via oxygen-charging. Acta Mater. 227, 117686 (2022)

Z. Yang, W. Xu, W. Zhang, Y. Chen, D. Shan, Effect of power spinning and heat treatment on microstructure evolution and mechanical properties of duplex low-cost titanium alloy. J. Mater. Sci. Technol. 136, 121–139 (2023)

G. Zheng, B. Tang, S. Zhao, W.Y. Wang, X. Chen, L. Zhu, J. Li, Evading the strength-ductility trade-off at room temperature and achieving ultrahigh plasticity at 800 ℃ in a TiAl alloy. Acta Mater. 225, 117585 (2022)

C.W. Shao, P. Zhang, Y.K. Zhu, Z.J. Zhang, Y.Z. Tian, Z.F. Zhang, Simultaneous improvement of strength and plasticity: additional work-hardening from gradient microstructure. Acta Mater. 145, 413–428 (2018)

H.H. Lee, H.K. Park, J. Jung, K.J. Hwang, H.S. Kim, Microstructural tailoring in reverse gradient-structured copper sheet using single-roll angular-rolling and subsequent annealing. Mater. Sci. Eng. A 764, 138258 (2019)

J. Yan, Q. Lai, J. Wang, Y. Shen, Saturation controlled softening/hardening in pure aluminum processed by surface rotation rolling. Scr. Mater. 182, 104–108 (2020)

P. Wang, Z. Chen, H. Huang, J. Lin, B. Li, Q. Liu, Fabrication of Ti/Al/Mg laminated composites by hot roll bonding and their microstructures and mechanical properties. Chin. J. Aeronaut. 34(8), 192–201 (2021)

M. Zha, X.H. Zhang, H. Zhang, J. Yao, C. Wang, H.Y. Wang, T.T. Feng, Q.C. Jiang, Achieving bimodal microstructure and enhanced tensile properties of Mg–9Al–1Zn alloy by tailoring deformation temperature during hard plate rolling (HPR). J. Alloys Compd. 765, 1228–1236 (2018)

R. Ma, C. Peng, Z. Cai, R. Wang, Z. Zhou, X. Li, X. Cao, Effect of bimodal microstructure on the tensile properties of selective laser melt Al–Mg–Sc–Zr alloy. J. Alloys Compd. 815, 152422 (2020)

Y. Wang, M. Chen, F. Zhou, E. Ma, High tensile ductility in a nanostructured metal. Nature 419(6910), 912–915 (2002)

S. Fu, J. Liu, Z. Wang, Strain hardening behavior of Ni-carbonyl Chemical Vapor Deposited (CVD) material with bimodal grain structures: ultrafine (UF) grains and large grains with UF/nano twins. Mater. Sci. Eng. A 751, 253–262 (2019)

X. Wu, M. Yang, F. Yuan, G. Wu, Y. Wei, X. Huang, Y. Zhu, Heterogeneous lamella structure unites ultrafine-grain strength with coarse-grain ductility. Proc. Natl. Acad. Sci. U S A 112(47), 14501–14505 (2015)

X.L. Wu, M.X. Yang, F.P. Yuan, L. Chen, Y.T. Zhu, Combining gradient structure and TRIP effect to produce austenite stainless steel with high strength and ductility. Acta Mater. 112, 337–346 (2016)

H. Du, Y. An, Y. Wei, X. Liu, L. Hou, B.-S. Liu, M.-M. Liu, P.K. Liaw, Experimental and numerical studies on strength and ductility of gradient-structured iron plate obtained by surface mechanical-attrition treatment. Mater. Sci. Eng. A 744, 471–480 (2019)

Y. Zhang, Z. Cheng, L. Lu, T. Zhu, Strain gradient plasticity in gradient structured metals. J. Mech. Phys. Solids 140, 103946 (2020)

X. Fu, Z. Yu, Z. Tan, G. Fan, P. Li, M. Wang, D.-B. Xiong, Z. Li, Enhanced strain hardening by bimodal grain structure in carbon nanotube reinforced Al–Mg composites. Mater. Sci. Eng. A 803, 140726 (2021)

N. Tsuchida, H. Masuda, Y. Harada, K. Fukaura, Y. Tomota, K. Nagai, Effect of ferrite grain size on tensile deformation behavior of a ferrite-cementite low carbon steel. Mater. Sci. Eng. A 488(1–2), 446–452 (2008)

M.R. Barnett, M.D. Nave, A. Ghaderi, Yield point elongation due to twinning in a magnesium alloy. Acta Mater. 60(4), 1433–1443 (2012)

R. Schwab, V. Ruff, On the nature of the yield point phenomenon. Acta Mater. 61(5), 1798–1808 (2013)

H. Shi, X. Guo, J. Li, J. Mao, W. Lu, The gradual disappearance of yield plateau in Zr–Sn–Nb–Fe–Mo alloy by the trace addition of Cr and V. Mater. Sci. Eng. A 760, 407–414 (2019)

H. Shi, J. Li, J. Mao, W. Lu, The elimination of the yield point phenomenon in a new zirconium alloy: influence of degree of recrystallization on the tensile properties. Scr. Mater. 169, 28–32 (2019)

H. Shi, J. Li, J. Mao, W. Lu, The gradual disappearance and re-appearance of yield drop by modulating the pre-strain history in a new zirconium alloy: dislocation decomposition and recombination. Scr. Mater. 188, 280–284 (2020)

W. Wen, J.G. Morris, The effect of cold rolling and annealing on the serrated yielding phenomenon of AA5182 aluminum alloy. Mater. Sci. Eng. A 373(1–2), 204–216 (2004)

A. Momeni, S.M. Abbasi, M. Morakabati, A. Akhondzadeh, Yield point phenomena in TIMETAL 125 beta Ti alloy. Mater. Sci. Eng. A 643, 142–148 (2015)

J. Wang, M.R.G. Ferdowsi, S.R. Kada, C.R. Hutchinson, M.R. Barnett, Influence of precipitation on yield elongation in Mg–Zn alloys. Scr. Mater. 160, 5–8 (2019)

Z. Li, L. Fu, B. Fu, A. Shan, Yield point elongation in fine-grained titanium. Mater. Lett. 96, 1–4 (2013)

M. Rezaee, A. Zarei-Hanzaki, A. Mohamadizadeh, E. Ghasemi, High-temperature flow characterization and microstructural evolution of Ti6242 alloy: yield drop phenomenon. Mater. Sci. Eng. A 673, 346–354 (2016)

X. Shi, Z. Cao, Z. Fan, R. Guo, J. Qiao, Probing into the yield plateau phenomenon in commercially pure Titanium during Tensile tests. Acta Metall. Sin. (Engl. Lett.) 34(5), 701–709 (2020)

J. Shen, B. Chen, J. Umeda, J. Zhang, Y. Li, K. Kondoh, An in-situ study on deformation and cracking initiation in oxygen-doped commercial purity titanium. Mech. Mater. 148, 103519 (2020)

K. Chen, D.J. Huang, H. Li, N. Jia, W. Chong, Avoiding abnormal grain growth when annealing selective laser melted pure titanium by promoting nucleation. Scr. Mater. 209, 114377 (2022)

J. Zhang, Y. Liu, M. Bayat, Q. Tan, Y. Yin, Z. Fan, S. Liu, J.H. Hattel, M. Dargusch, M.-X. Zhang, Achieving high ductility in a selectively laser melted commercial pure-titanium via in-situ grain refinement. Scr. Mater. 191, 155–160 (2021)

F. Yan, W. Xiong, E. Faierson, G.B. Olson, Characterization of nano-scale oxides in austenitic stainless steel processed by powder bed fusion. Scr. Mater. 155, 104–108 (2018)

O.O. Salman, C. Gammer, A.K. Chaubey, J. Eckert, S. Scudino, Effect of heat treatment on microstructure and mechanical properties of 316L steel synthesized by selective laser melting. Mater. Sci. Eng. A 748, 205–212 (2019)

T. Kusama, T. Omori, T. Saito, S. Kise, T. Tanaka, Y. Araki, R. Kainuma, Ultra-large single crystals by abnormal grain growth. Nat. Commun. 8(1), 354 (2017)

X. Li, J.J. Shi, G.H. Cao, A.M. Russell, Z.J. Zhou, C.P. Li, G.F. Chen, Improved plasticity of Inconel 718 superalloy fabricated by selective laser melting through a novel heat treatment process. Mater. Des. 180, 107915 (2019)

M. Jafari, M. Jamshidian, S. Ziaei-Rad, D. Raabe, F. Roters, Constitutive modeling of strain induced grain boundary migration via coupling crystal plasticity and phase-field methods. Int. J. Plast. 99, 19–42 (2017)

H. Wang, Q. Chao, L. Yang, M. Cabral, Z.Z. Song, B.Y. Wang, S. Primig, W. Xu, Z.B. Chen, S.P. Ringer, X.Z. Liao, Introducing transformation twins in titanium alloys: an evolution of α-variants during additive manufacturing. Mater. Res. Lett. 9(3), 119–126 (2020)

G.C. Obasi, S. Birosca, J. Quinta da Fonseca, M. Preuss, Effect of β grain growth on variant selection and texture memory effect during α→β→α phase transformation in Ti–6 Al–4V. Acta Mater. 60(3), 1048–1058 (2012)

Y. Chen, L. Jin, J. Dong, Z. Zhang, F. Wang, Twinning effects on the hot deformation behavior of AZ31Mg alloy. Mater. Charact. 118, 363–369 (2016)

J. Fan, J. Li, Y. Zhang, H. Kou, L. Germain, N. Siredey-Schwaller, C. Esling, Microstructure and crystallography of α phase nucleated dynamically during thermo-mechanical treatments in metastable β. Titan. Alloy Adv. Eng. Mater. 19(7), 1600859 (2017)

L.P. Kubin, A. Mortensen, Geometrically necessary dislocations and strain-gradient plasticity: a few critical issues. Scr. Mater. 48(2), 119–125 (2003)

C. Moussa, M. Bernacki, R. Besnard, N. Bozzolo, About quantitative EBSD analysis of deformation and recovery substructures in pure Tantalum. IOP Conf. Ser. Mater. Sci. Eng. 89, 012038 (2015)

W.G. Johnston, J.J. Gilman, D. Velocities, Dislocation densities, and Plastic Flow in Lithium Fluoride crystals. J. Appl. Phys. 30(2), 129–144 (1959)

H. Conrad, Effect of interstitial solutes on the strength and ductility of titanium. Prog. Mater. Sci. 26(2), 123–403 (1981)

J. Kacher, B.P. Eftink, B. Cui, I.M. Robertson, Dislocation interactions with grain boundaries. Curr. Opin. Solid State Mater. Sci. 18(4), 227–243 (2014)

M.-S. Lee, A.R. Jo, S.-K. Hwang, Y.-T. Hyun, T.-S. Jun, The role of strain rate and texture in the deformation of commercially pure titanium at cryogenic temperature. Mater. Sci. Eng. A 827, 142042 (2021)

W. Shi, S. Lu, J. Shen, B. Chen, J. Umeda, Q. Wei, K. Kondoh, Y. Li, ASB induced phase transformation in high oxygen doped commercial purity Ti. Mater. Sci. Eng. A 830, 142321 (2022)

A.H. Cottrell, B.A. Bilby, Dislocation theory of yielding and strain ageing of iron. Proc. Phys. Soc. Sect. A 62(1), 49–62 (1949)

G. Schoeck, A. Seeger, The flow stress of iron and its dependence on impurities. Acta Metall. 7(7), 469–477 (1959)

N.G. Turner, W.T. Roberts, Dynamic strain ageing in titanium. J. Less Common Met. 16(1), 37–44 (1968)

A.T. Santhanam, R.E. Reed-Hill, Work hardening peaks in α-titanium. Scr. Metall. 4(7), 529–531 (1970)

S.N. Monteiro, R.E. Reed-Hill, An empirical analysis of titanium stress-strain curves. Metall. Trans. 4(4), 1011–1015 (1973)

A.T. Churchman, The yield phenomena, kink bands and geometric softening in titanium crystals. Acta Metall. 3(1), 22–29 (1955)

H. Mughrabi, On the current understanding of strain gradient plasticity. Mater. Sci. Eng. A 387–389, 209–213 (2004)

D. Akama, N. Nakada, T. Tsuchiyama, S. Takaki, A. Hironaka, Discontinuous yielding induced by the addition of nickel to interstitial-free steel. Scr. Mater. 82, 13–16 (2014)

X. Ma, C. Huang, J. Moering, M. Ruppert, H.W. Höppel, M. Göken, J. Narayan, Y. Zhu, Mechanical properties of copper/bronze laminates: role of interfaces. Acta Mater. 116, 43–52 (2016)

H. Zhi, C. Zhang, S. Antonov, H. Yu, T. Guo, Y. Su, Investigations of dislocation-type evolution and strain hardening during mechanical twinning in Fe–22Mn–0.6 C twinning-induced plasticity steel. Acta Mater. 195, 371–382 (2020)

N. Wang, Y. Chen, G. Wu, Q. Zhao, Z. Zhang, L. Zhu, J. Luo, Non-equivalence contribution of geometrically necessary dislocation and statistically stored dislocation in work-hardened metals. Mater. Sci. Eng. A 836, 142728 (2022)

Acknowledgements

This work is supported by the National Natural Science Foundation of China (11802247) and the 111 Project (No. BP0719007).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no financial and personal relationships with other people or organizations that can inappropriately influence our work.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Shi, X., Wang, X., Chen, B. et al. Effect of Bimodal Grain Structure on the Yielding Behavior of Commercial Purity Titanium Under Quasi-static Tension. Met. Mater. Int. 29, 2207–2215 (2023). https://doi.org/10.1007/s12540-022-01373-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-022-01373-8