Abstract

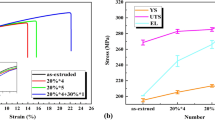

Significant tension-compression (T–C) yield asymmetry in common wrought Mg alloys hinders their widespread applications. A double extrusion process with variable speed and partially substituted yttrium (Y) (2 wt%) for Sn was proposed to improve the T–C asymmetry of Mg–2.5Sn (wt%) alloy, and then to explore the critical grain size parameter for T–C symmetry. The result showed that the individual double extrusion or partial substitution of Sn by Y slightly refined the grains of Mg–2.5Sn alloy (from ~ 42.5 µm to 35.5 µm and 31.2 µm, respectively), along with the improved T–C asymmetry (CYS/TYS) from 0.44 to 0.51 and 0.75, respectively. When combining the above two factors, the double-extruded Mg–Sn–Y alloys obtained fine grains with ~ 8.8 µm and gained a T–C yield symmetry (CYS/TYS = 1.01). By tailoring the extrusion speed from the previous 1.2 mm/s to 2 mm/s, the grain size of double-extruded Mg–Sn–Y further deduced to ~ 5.6 µm and turned to be a reversed T–C asymmetry (CYS/TYS) of 1.37. The refined grain size combined with weakened texture led to a decreased activation or even inhibition of tension twinning and increased activation of non-basal slip, which might be the main reason for the improved or even reversed T–C asymmetry in double-extruded Mg–0.5Sn–2Y.

Graphical Abstract

Similar content being viewed by others

References

X. Zhuo, L. Zhao, W. Gao, Y. Wu, H. Liu, P. Zhang, Z. Hu, J. Jiang, A. Ma, J. Mater. Res. Technol. 21, 186–211 (2022)

C. Liu, H. Chen, M. Song, J.-F. Nie, J. Magnes. Alloy. 10, 1909–1914 (2022)

D. Bovand, H. Abdollah-Pour, O. Mirzaee, S. Bagherifard, J. Mater. Eng. Perform. 31, 6835–6845 (2022)

L. Zhong, Y. Wang, Y. Dou, J. Magnes. Alloy. 7, 637–647 (2019)

A. Orozco-Caballero, D. Lunt, J.D. Robson, and J. Quinta da Fonseca. Acta Mater. 133, 367–379 (2017)

S.A. Habib, A.S. Khan, T. Gnäupel-Herold, J.T. Lloyd, S.E. Schoenfeld, Int. J. Plasticity 95, 163–190 (2017)

H. Li, C. Yu, G. Kang, Int. J. Plasticity 152, 103242 (2022)

T. Li, J. Rao, J. Zheng, D. Yin, H. Shou, Y. Zhang, R. Shi, W. Jing, L. Xia, J. Magnes. Alloy. 10, 1581–1597 (2022)

B. Shi, C. Yang, Y. Peng, F. Zhang, F. Pan, J. Magnes. Alloy. 10, 1476–1510 (2022)

Q. Wang, B. Jiang, D. Chen, Z. Jin, L. Zhao, Q. Yang, G. Huang, F. Pan, J. Mater. Sci. 56, 12965–12998 (2021)

S. Sandlöbes, S. Zaefferer, I. Schestakow, S. Yi, R. Gonzalez-Martinez, Acta Mater. 59, 429–439 (2011)

X. Wang, L. Jiang, D. Zhang, I.J. Beyerlein, S. Mahajan, T.J. Rupert, E.J. Lavernia, J.M. Schoenung, Acta Mater. 146, 12–24 (2018)

E. Dogan, I. Karaman, G. Ayoub, G. Kridli, Mater. Sci. Eng. A 610, 220–227 (2014)

X.Y. Qian, Y. Zeng, B. Jiang, Q.R. Yang, Y.J. Wan, G.F. Quan, F.S. Pan, J. Alloy. Compd. 820, 153122 (2020)

A.E. Davis, J.D. Robson, M. Turski, Mater. Sci. Eng. A 744, 525–537 (2019)

D.D. Yin, C.J. Boehlert, L.J. Long, G.H. Huang, H. Zhou, J. Zheng, Q.D. Wang, Int. J. Plasticity 136, 102878 (2021)

H.D. Zhao, G.W. Qin, Y.P. Ren, W.L. Pei, Y. Guo, J. Alloy. Compd. 481, 140–143 (2009)

L. Wang, G. Huang, Q. Quan, P. Bassani, E. Mostaed, M. Vedani, F. Pan, Mater. Design 63, 177–184 (2014)

G. Shi, J. Yuan, T. Li, K. Zhang, X. Li, Y. Li, M. Ma, Mater. Sci. Eng. A 774, 138906 (2020)

I. Basu, T. Al-Samman, Acta Mater. 96, 111–132 (2015)

N. Stanford, M.R. Barnett, Mater. Sci. Eng. A 496, 399–408 (2008)

C.J. Geng, B.L. Wu, X.H. Du, Y.D. Wang, Y.D. Zhang, F. Wagner, C. Esling, Mater. Sci. Eng. A 559, 307–313 (2013)

J. Jain, W.J. Poole, C.W. Sinclair, M.A. Gharghouri, Scripta Mater. 62, 301–304 (2010)

M. Lentz, M. Klaus, I.J. Beyerlein, M. Zecevic, W. Reimers, M. Knezevic, Acta Mater. 86, 254–268 (2015)

Z. Fan, F. Gao, Y. Wang, H. Men, L. Zhou, Prog. Mater. Sci. 123, 100809 (2022)

Z. Fan, Y. Wang, M. Xia, S. Arumuganathar, Acta Mater. 57, 4891–4901 (2009)

B.S. Murty, S.A. Kori, M. Chakraborty, Int. Mater. Rev. 47, 3–29 (2013)

D. Shu, B. Sun, J. Mi, P.S. Grant, Acta Mater. 59, 2135–2144 (2011)

T.E. Quested, A.T. Dinsdale, A.L. Greer, Acta Mater. 53, 1323–1334 (2005)

Y. Zeng, B. Jiang, M.X. Zhang, H.M. Yin, R.H. Li, F.S. Pan, Intermetallics 45, 18–23 (2014)

M.R. Barnett, Z. Keshavarz, A.G. Beer, D. Atwell, Acta Mater. 52, 5093–5103 (2004)

A. Akhtar, E. Teghtsoonian, Acta Metall. 17, 1339–1349 (1969)

Y.Z. Du, M.Y. Zheng, X.G. Qiao, K. Wu, X.D. Liu, G.J. Wang, X.Y. Lv, M.J. Li, X.L. Liu, Z.J. Wang, Y.T. Liu, Mater. Sci. Eng. A 583, 69–77 (2013)

J.D. Robson, N. Stanford, M.R. Barnett, Scripta Mater. 63, 823–826 (2010)

J.D. Robson, Acta Mater. 121, 277–287 (2016)

Z. Wu, R. Ahmad, B. Yin, S. Sandlöbes, W.A. Curtin, Science 359, 447–452 (2018)

D. Zhang, H. Wen, M.A. Kumar, F. Chen, L. Zhang, I.J. Beyerlein, J.M. Schoenung, S. Mahajan, E.J. Lavernia, Acta Mater. 120, 75–85 (2016)

Acknowledgments

The authors gratefully acknowledge the National Natural Science Foundation of China (52004227, 52171125 and U1764253), Jihua Laboratory and GuangDong Basic and Applied Basic Research Foundation (2020A1515110262), Fundamental Research Funds for the Central Universities (2682020ZT114), and the Fundamental Research Funds for Southwest Jiaotong University (2682021ZTPY001). We also thank the Analytical and Testing Center of Southwest Jiaotong University for assistance with EBSD experiments.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic Supplementary Material

Below is the link to the electronic supplementary material

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zeng, Y., Xiong, X., Qian, X. et al. Achieving Improved/Reversed Tension–Compression Asymmetry by Tailoring Extrusion Processing for Mg–Sn(–Y) Alloy. Met. Mater. Int. 29, 1885–1895 (2023). https://doi.org/10.1007/s12540-022-01357-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-022-01357-8